Self-energizing inertia lock key type synchronizer

A self-energizing and synchronizer technology, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., to achieve the effects of reduced ring-setting force, simple mold manufacturing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

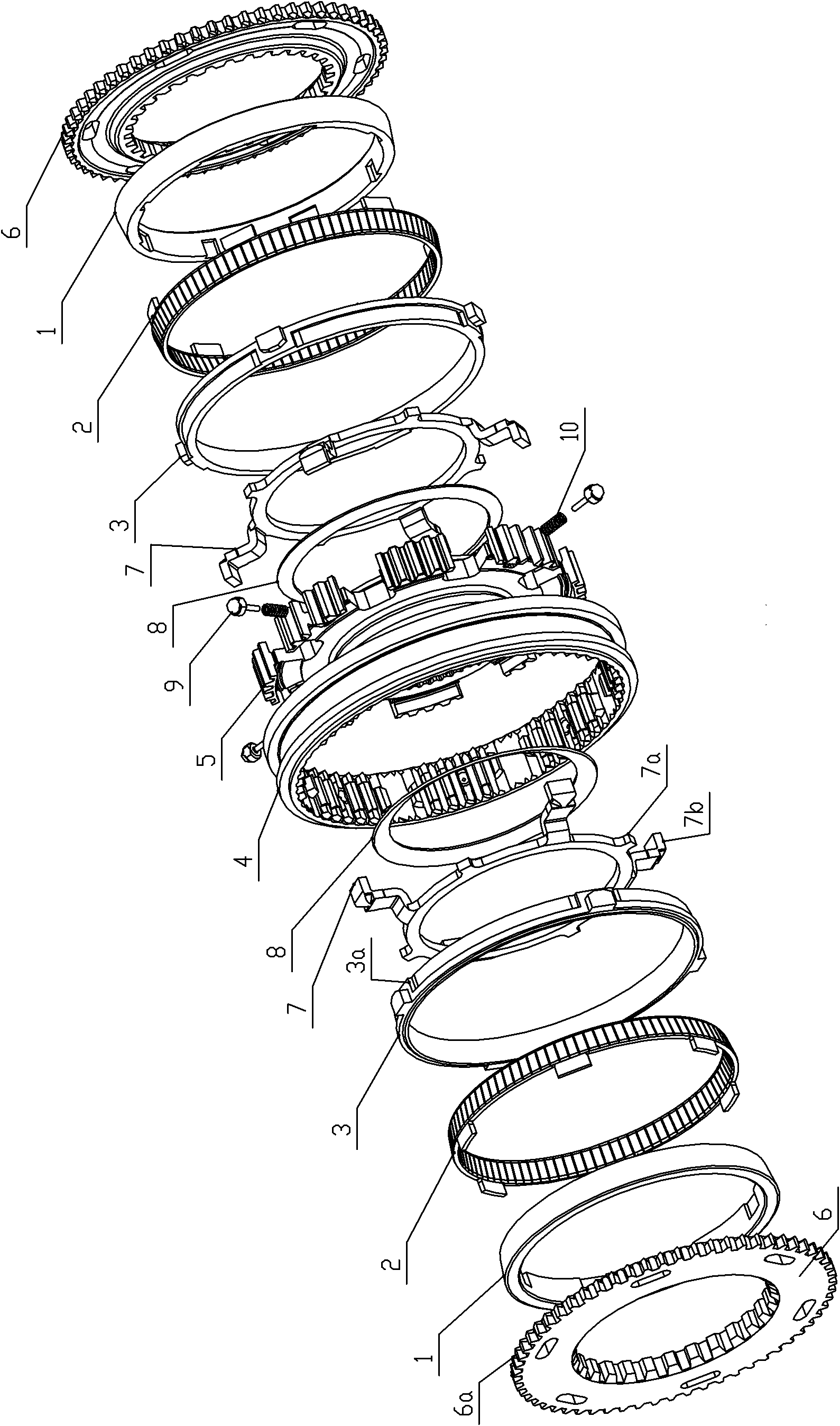

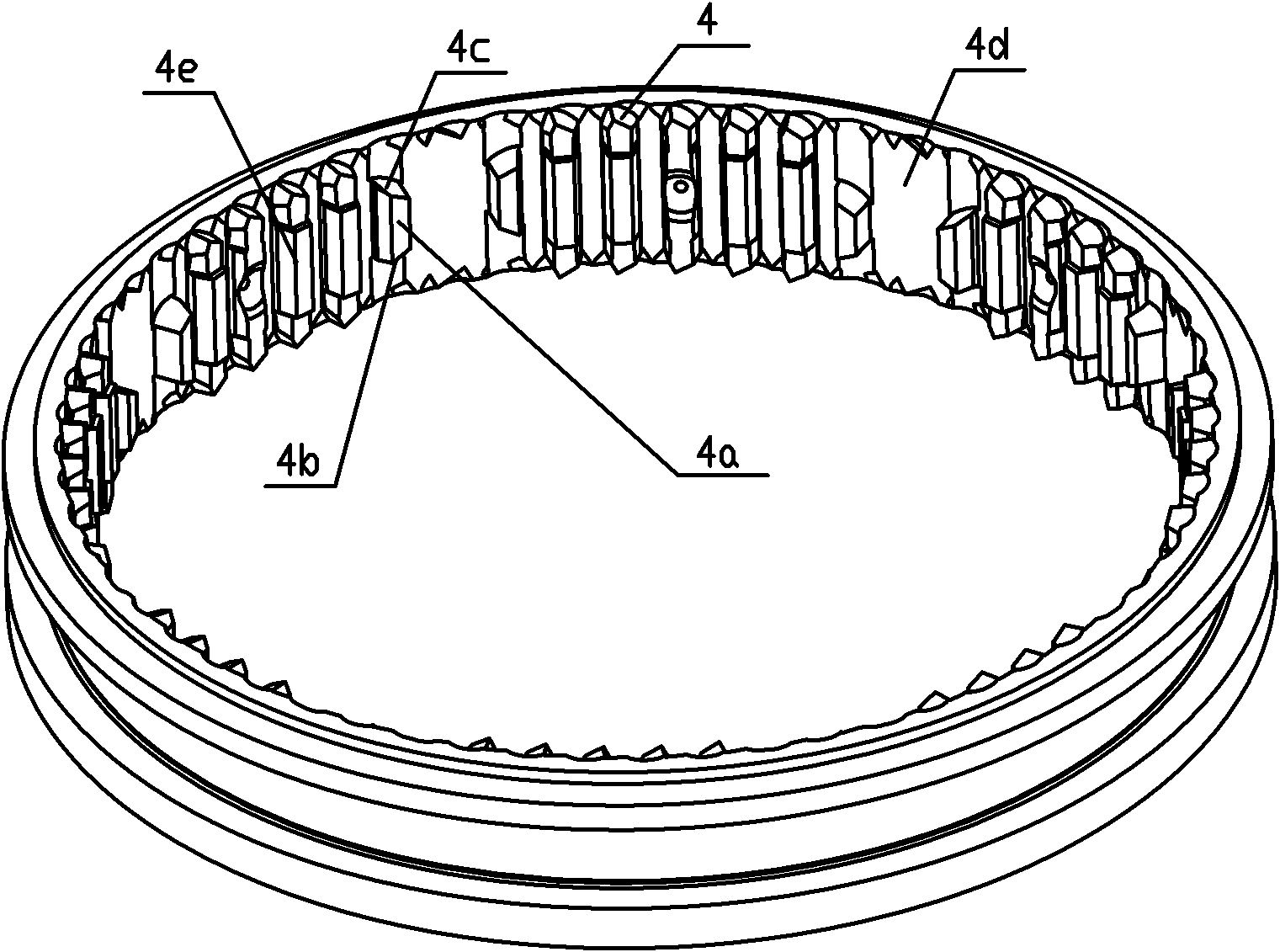

[0022] Such as figure 1 As shown, this embodiment includes double-cone synchronous ring friction components: two inner rings 1, two intermediate rings 2 and two outer rings 3; teeth meshing components: a sliding sleeve 4, a tooth seat 5 and two combined Teeth 6; pre-synchronization components: evenly distributed push blocks 9 and springs 10; double-cone synchronous ring friction components use conical surface friction to roughly synchronize the coupling teeth 6 and sliding sleeve 4, the sliding sleeve 4 enters the coupling teeth 6, and the sliding sleeve 4 is connected with the gear seat 5 by sliding splines, and also includes self-energizing components: two stamping rings 7 and two disc springs 8, and the disc springs 8 are arranged between the tooth seat 5 and the stamping ring 7;

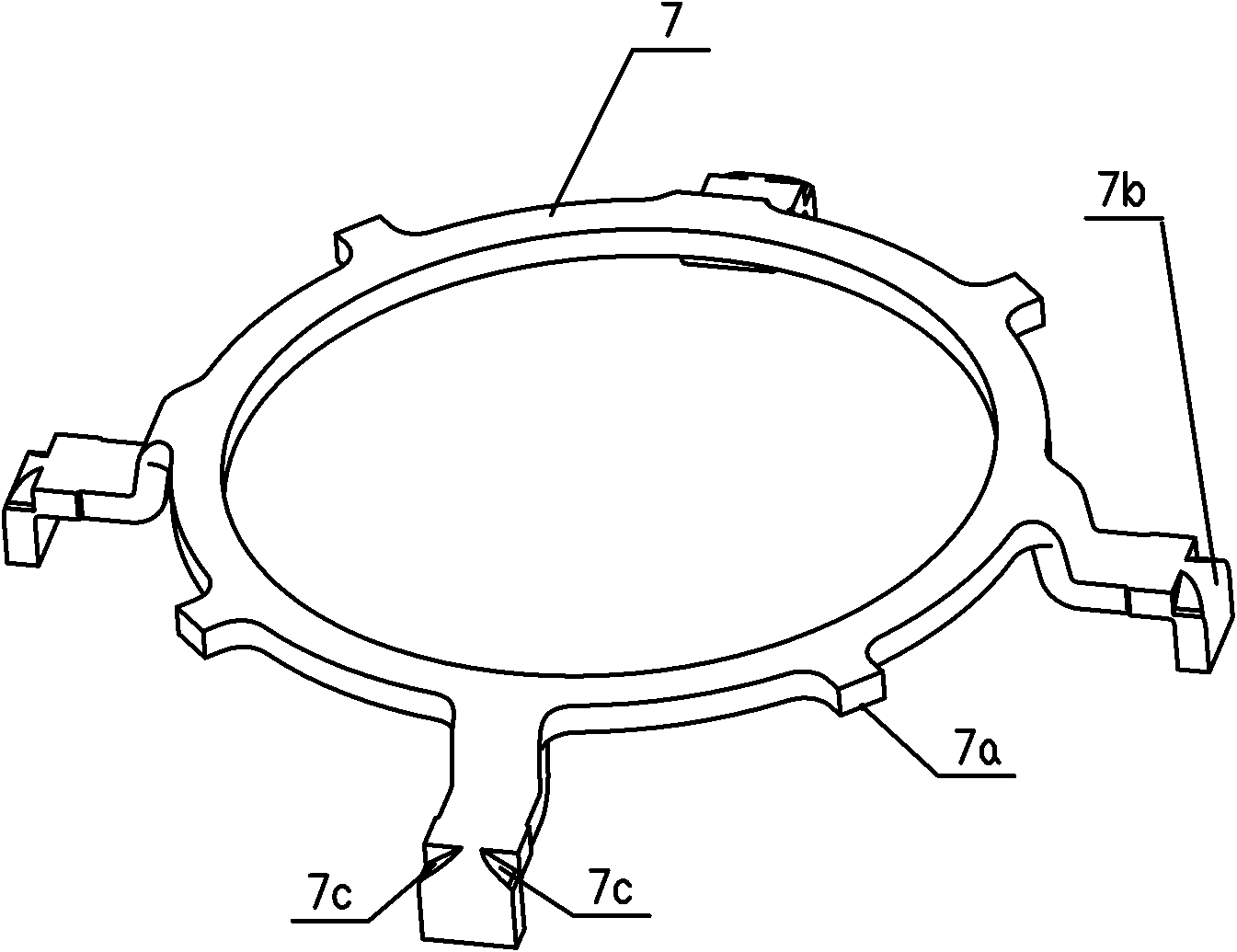

[0023] Such as figure 2 As shown, the stamping ring 7 is a ring structure with a mounting boss 7a on the outer ring, claws 7b are evenly arranged on the outer ring of the stamping ring 7, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com