Fuel oil heater of fuel oil filters

A fuel heater and fuel filter technology, applied in fuel heat treatment devices, combustion air/combustion-air treatment, machines/engines, etc., can solve the problem that the temperature control temperature cannot reflect the change of fuel temperature in time, PTC sheet and Problems such as poor contact of the electrode plate and uneven force on the PTC sheet achieve the effects of self-control of temperature, saving raw materials, and firm and reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further explain in detail in conjunction with accompanying drawings;

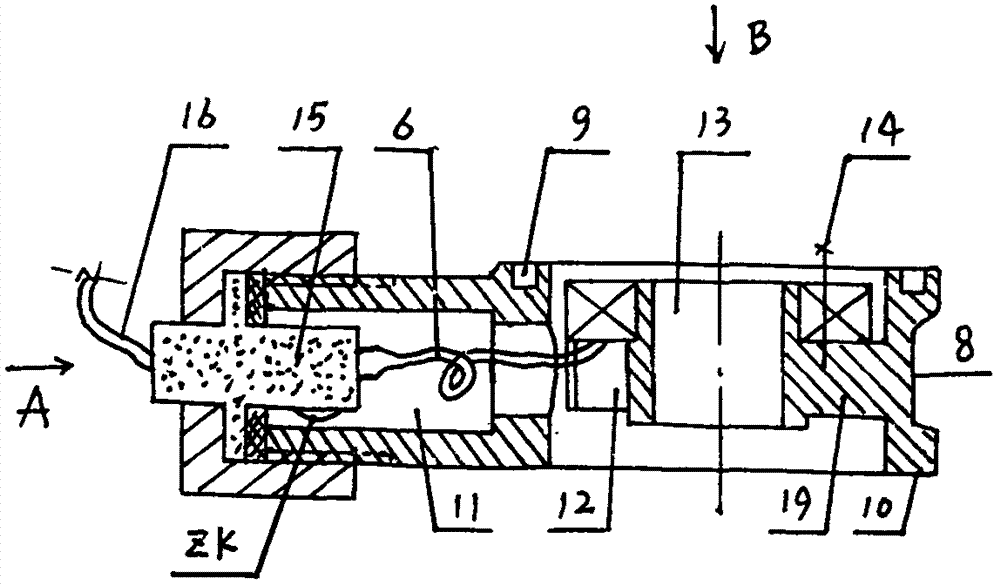

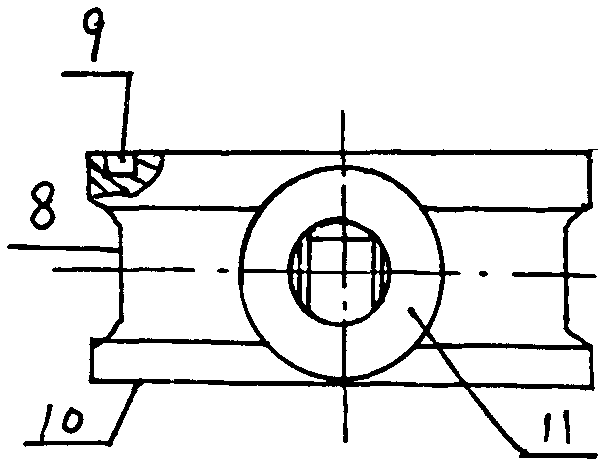

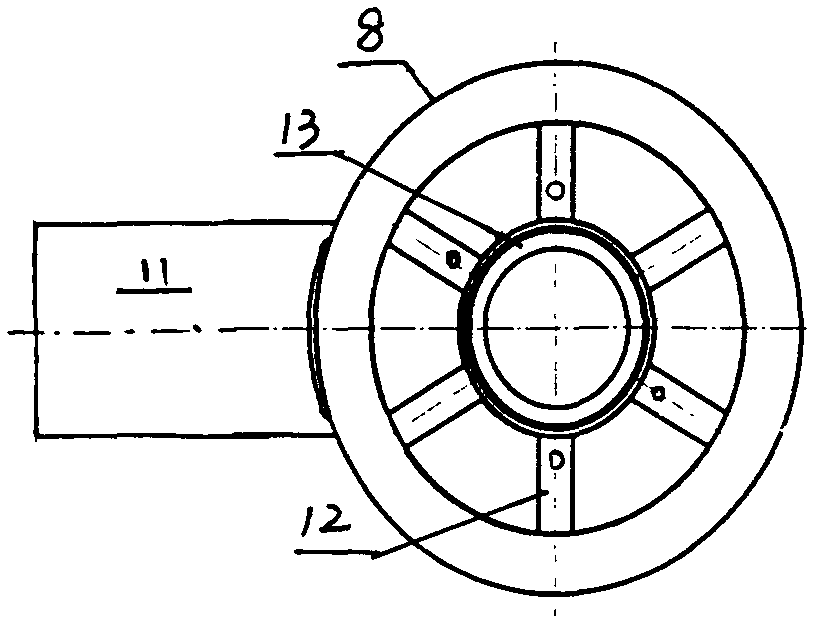

[0019] Such as Figure 1~5 As shown, each thermistor heating chip PTC and its corresponding electrode plate G and electrode lead L in the heater circuit are called heating units 2. After each heating unit 2 is connected in parallel and / or in series regularly, the external insulation and sealing and regularly distributed in the heating body, and the electrode plates of each heating unit 2 are integrally pre-compressed and electrically connected with the corresponding thermistor heating sheet PTC, and the heating body is drawn out from the external insulation and sealing Two electrode wiring;

[0020] The heating body is detachably installed on the mounting frame, which is integrally processed with metal material, and the cylindrical main body 8 with the upper and lower sealing ports 9, 10 has a lead wire 16 for external power supply and holds the sealing The threaded bypass interface 11 of the intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com