Water cooling structure for multi-cylinder engine

A multi-cylinder engine, water cooling technology, applied in the direction of engine cooling, engine components, machine/engine, etc., can solve the problem of independent cooling, cooling uniformity and cooling performance consistency cannot be well guaranteed, and can not achieve uniform cooling of the combustion chamber And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

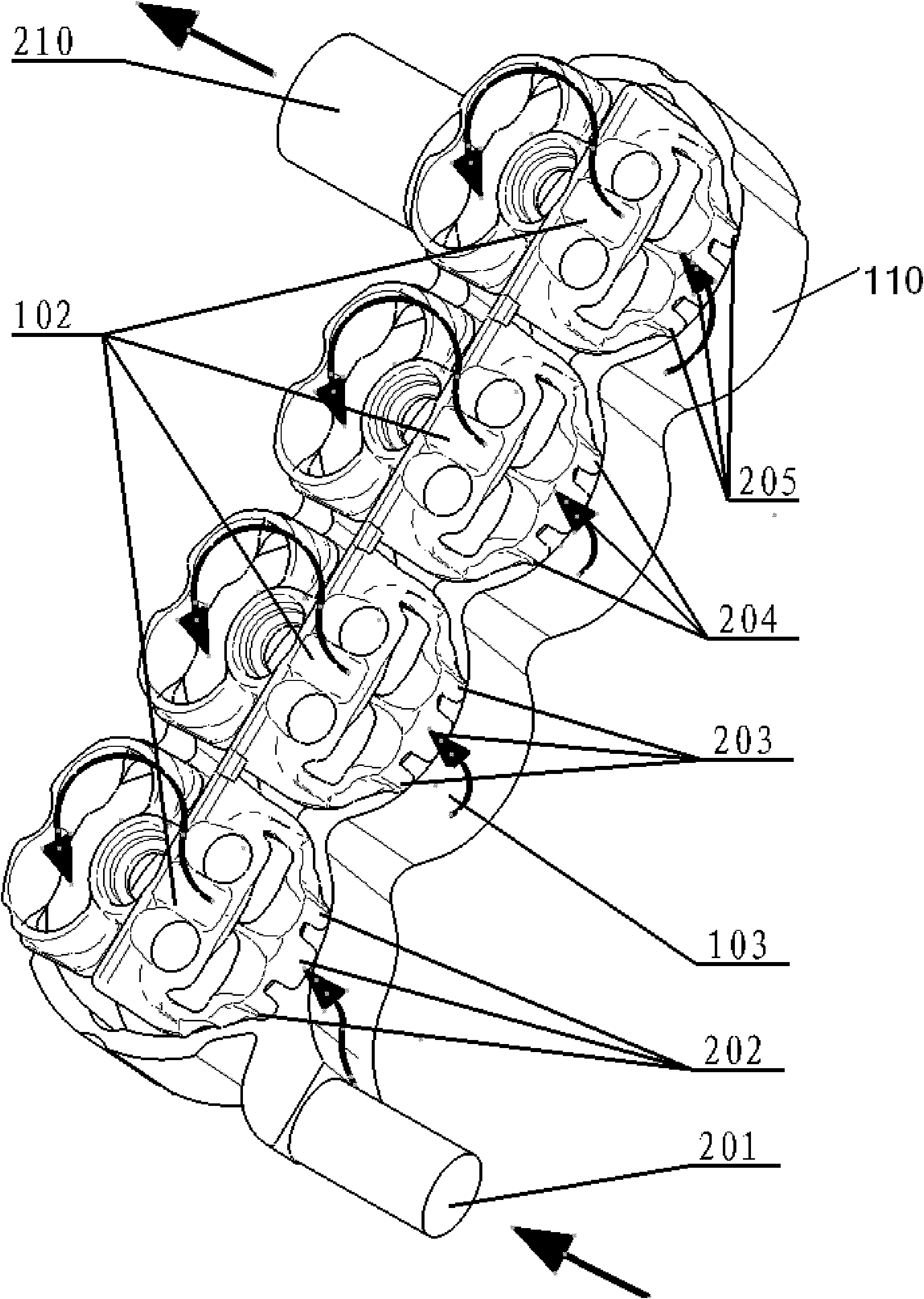

[0021] Such as figure 1 As shown, the cooling system for the multi-cylinder engine includes a water pump 101, a cylinder block cooling water flow channel 103, a cylinder head cooling water flow channel 102, a thermostat 104, a radiator 109, an oil cooler 106, a liquid storage bottle 108, and a heating ventilator 105 and small circulation pipe 107. Wherein thermostat 104, radiator 109, engine oil cooler 106, liquid storage bottle 108, heating ventilator 105 and small circulation pipe 107 adopt existing common arrangement form to communicate with each other.

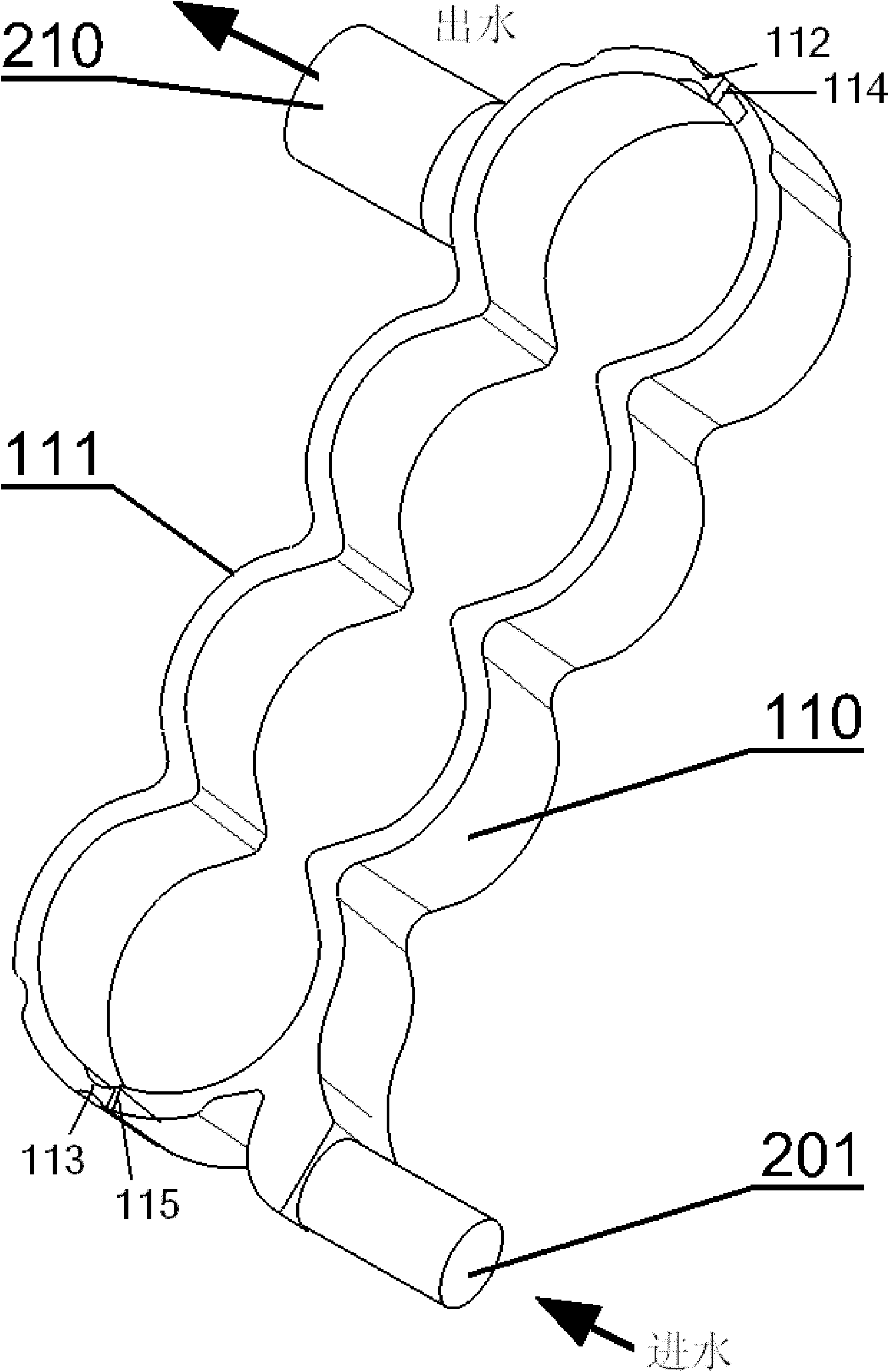

[0022] Such as image 3 As shown, the cylinder block cooling water channel 103 is cast in the area surrounding the piston cylinder in the multi-cylinder engine block, and the cylinder block cooling water channel 103 is divided into the front exhaust side cylinder cooling water channel section 110 and the rear intake side cylinder block Two damping holes 112, 113 are provided between the cooling water flow passage section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com