Anti-pollution flashover normal-temperature cured fluorocarbon resin coating and preparation method thereof

A room temperature curing, fluorocarbon resin technology, used in epoxy resin coatings, antifouling/underwater coatings, chemical instruments and methods, etc., can solve inconvenient preventive tests and maintenance work, short service life of silicone oil, difficult to clean and other problems, to achieve the effect of excellent hydrophobicity and hydrophobic migration performance, good chemical resistance and good hot water performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 Antifouling flash fluorocarbon resin coating (with primer)

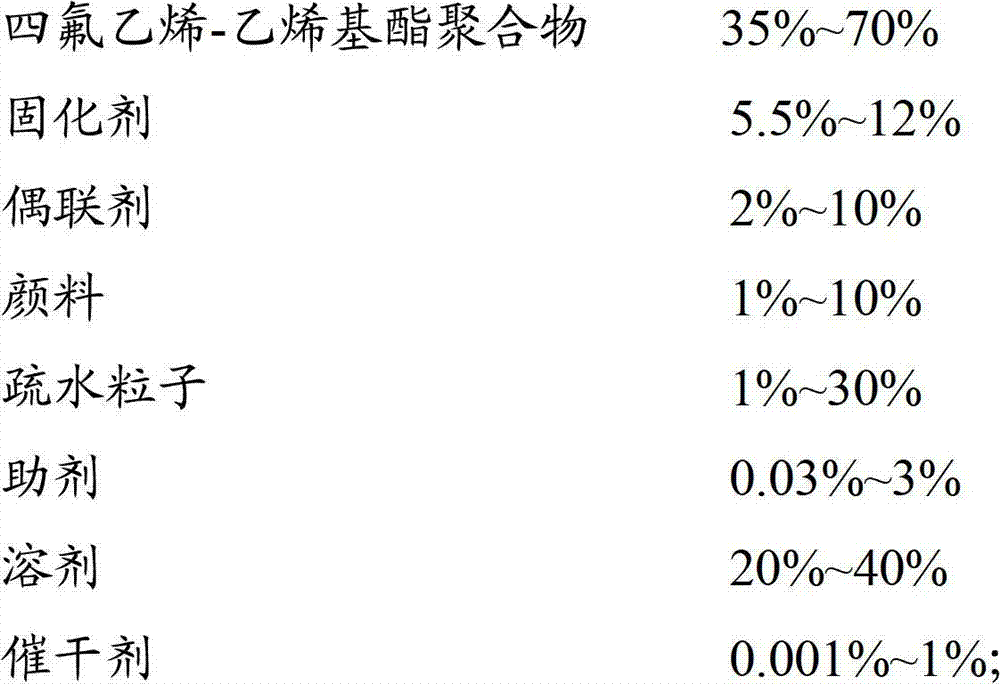

[0042] top coat

[0043] Tetrafluoroethylene-vinyl ester polymer 70kg

[0044] HDI trimer N3390 (curing agent) 9kg

[0045] Coupling agent 4kg

[0046]Rutile TiO 2 (Pigment) 4.5kg

[0047] Vapor SiO 2 (hydrophobic particles) 7kg

[0048] Leveling agent BYK310 (auxiliary) 1kg

[0049] Defoamer 100# (auxiliary) 0.7kg

[0050] Dispersant FC-4430 (auxiliary) 0.1kg

[0051] Butyl acetate: MIBK=2:1 (solvent) 51kg

[0052] Dibutyltin dilaurate (drying agent) 1kg

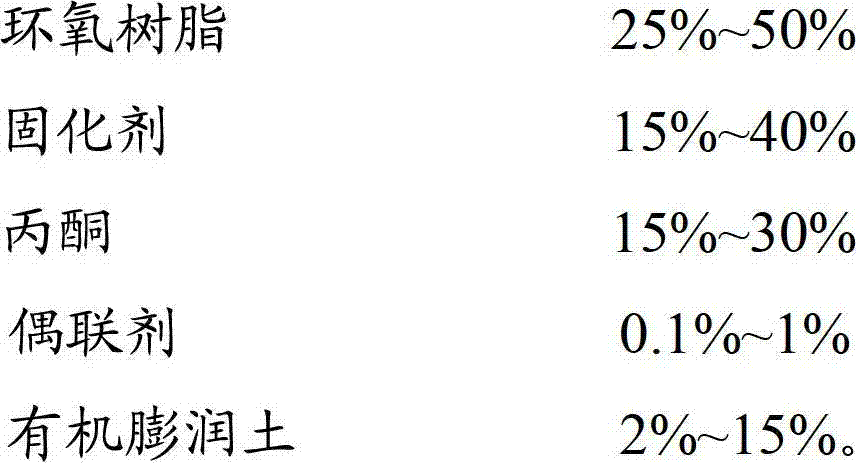

[0053] Primer

[0054] E-44 (epoxy resin) 100kg

[0055] Modified amine: polyamide 650=3:4 (curing agent) 70kg

[0056] KH550 (coupling agent) 1kg

[0057] BK-886 (bentonite) 20kg

[0058] Acetone 60kg

[0059] The preparation method of the coating of embodiment 1 is:

[0060] (1) Add acetone to E-44, add polyamide 650 and stir evenly;

[0061] (2) Add bentonite BK-886 into the system of step (1), stir well, then add silane co...

Embodiment 2

[0067] Embodiment 2 Antifouling flash fluorocarbon resin coating (with primer)

[0068] Topcoat:

[0069] Tetrafluoroethylene-vinyl ester polymer 250kg

[0070] HDI trimer N3390 (curing agent) 30kg

[0071] Coupling agent 30kg

[0072] Rutile TiO 2 (Pigment) 15kg

[0073] PTFE micropowder (hydrophobic particles) 70kg

[0074] Vapor SiO 2 (hydrophobic particles) 7kg

[0075] Leveling agent BYK310 (auxiliary) 2.5kg

[0076] Defoamer 100# (auxiliary) 1.5kg

[0077] Dispersant FC-4430 (auxiliary) 0.4kg

[0078] Butyl acetate: MIBK=2:1 (solvent) 120kg

[0079] Dibutyltin dilaurate (drying agent) 2kg

[0080] Primer:

[0081] E-44 (epoxy resin) 150kg

[0082] Modified amine: polyamide 650=3:7 (curing agent) 100kg

[0083] KH550 (coupling agent) 2kg

[0084] BK-886 (bentonite) 35kg

[0085] Acetone 100kg

[0086] The preparation method of the coating of embodiment 2 is:

[0087] (1) Add acetone to E-44, add polyamide 650 and stir evenly;

[0088] (2) Add bentonite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com