Acrylic acid non-aqueous dispersoid containing amino ester bonds and siloxy groups and preparation method thereof

A non-aqueous dispersion and siloxane-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of not much polar group content, solvent resistance, chemical resistance, and water resistance of the coating film Not as good as other problems, to achieve excellent solvent resistance, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares the acrylic acid non-aqueous dispersion A containing urethane bond and siloxane group

[0027] ① Preparation of dispersion stabilizer

[0028](1) Preparation of raw materials

[0029] The raw material formula that is used to synthesize the prepolymer containing urethane bond is shown in Table 1

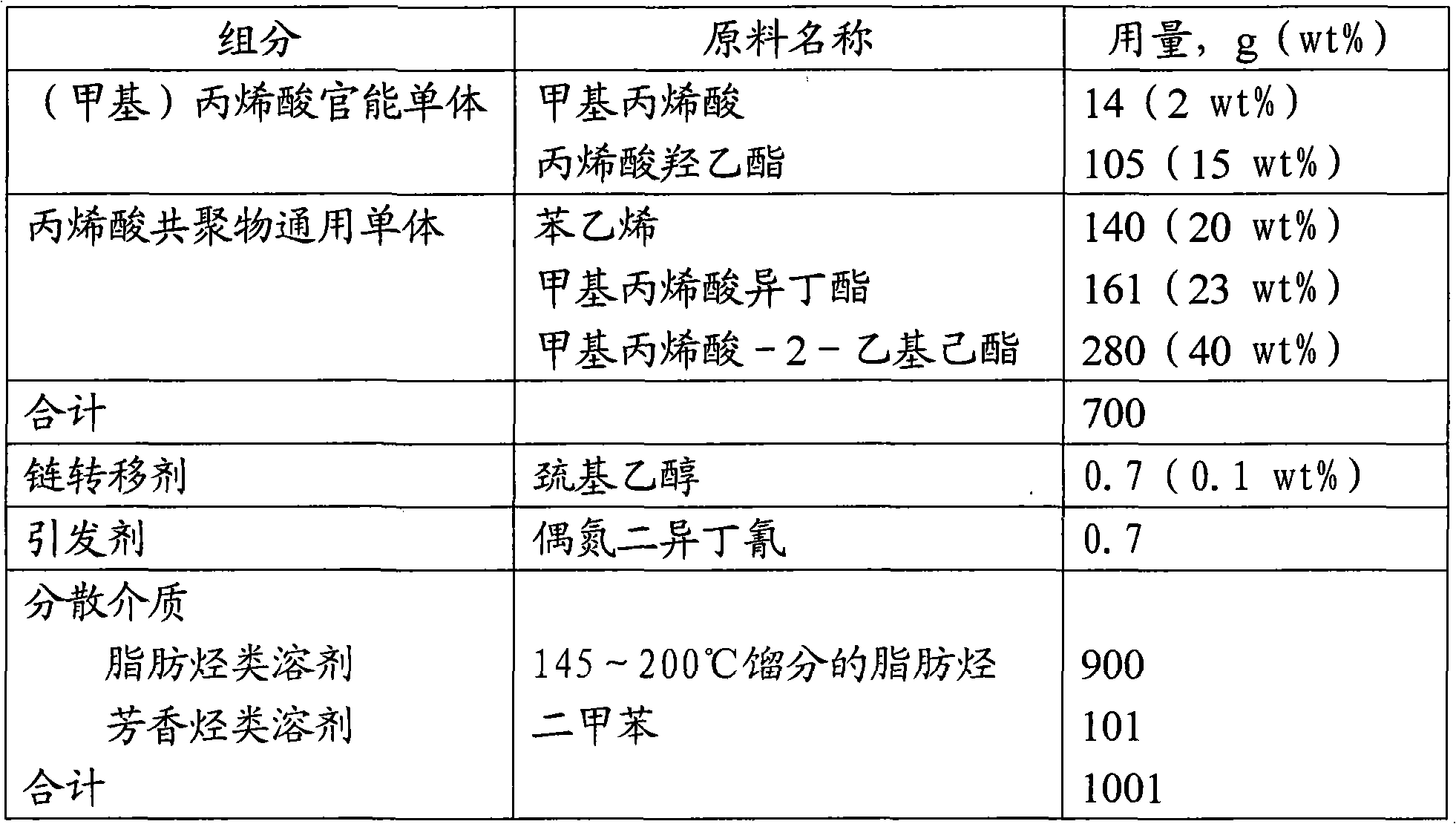

[0030] Table 1

[0031] raw material name

Dosage, g (equivalent to mol)

Hexamethylene diisocyanate (molecular weight 168)

158(0.941)

Propylene glycol (molecular weight 76)

47.6(0.627)

Hydroxyethyl Acrylate (Molecular Weight 116)

36.31(0.313=1 / 3×0.941)

Dodecyl ammonia (molecular weight 185)

57.91(0.313=1 / 3×0.941)

total

300g

[0032] Explanation: In Table 4, the molar ratio of hexamethylene diisocyanate to propylene glycol is 0.941:0.627, which is equivalent to 3:2, that is, n=3;

[0033] All the other raw material formulations for the synthesis of dispersion stabilizer are sh...

Embodiment 2

[0045] Embodiment 2 prepares the acrylic acid nonaqueous dispersion B containing urethane bond and siloxane group

[0046] ① Preparation of dispersion stabilizer

[0047] (1) Preparation of raw materials

[0048] The raw material formulation that is used to synthesize the prepolymer containing urethane bond is shown in Table 4

[0049] Table 4

[0050] raw material name

Dosage, g (equivalent to mol)

Hexamethylene diisocyanate (molecular weight 168)

168.0(1)

Butanediol (molecular weight 90)

72.0(0.8)

Hydroxyethyl Acrylate (Molecular Weight 116)

23.2(0.2=1 / 5×1)

Dodecyl ammonia (molecular weight 185)

37.0(0.2=1 / 5×1)

total

300g

[0051] Explanation: In Table 4, the molar ratio of hexamethylene diisocyanate to propylene glycol is 1:0.8, which is equivalent to 5:4, that is, n=5;

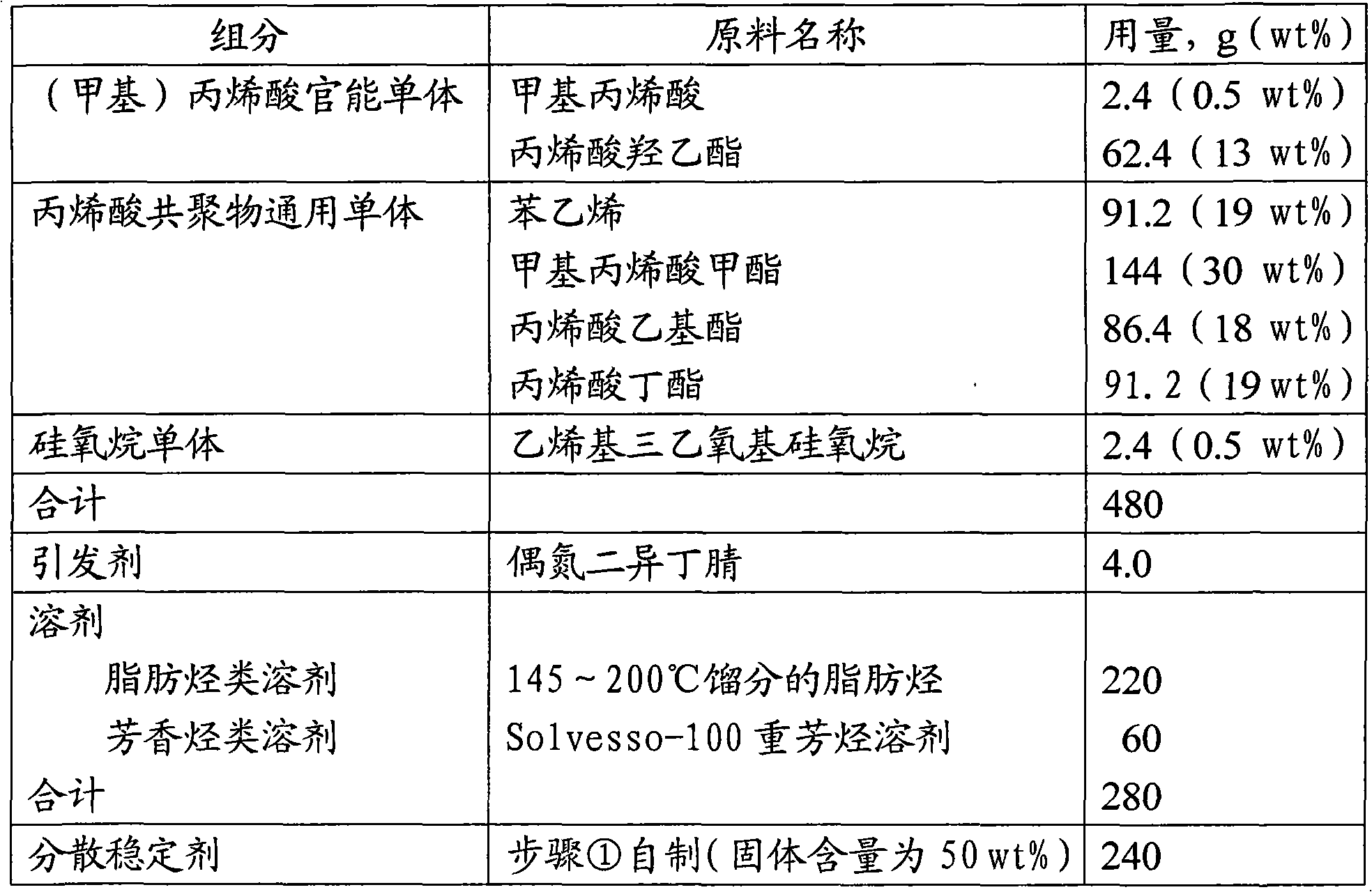

[0052] All the other raw material formulations for the synthesis of dispersion stabilizer are shown in Table 5

[0053] t...

Embodiment 3

[0064] Embodiment 3 prepares the acrylic acid nonaqueous dispersion C containing urethane bond and siloxane group

[0065] ① Preparation of dispersion stabilizer

[0066] (1) Preparation of raw materials

[0067] The raw material formula table 7 that is used for synthesizing the prepolymer containing urethane bond.

[0068] Table 7

[0069] raw material name

Dosage, g (equivalent to mol)

[0070] Hexamethylene diisocyanate (molecular weight 168)

174.89(1.041)

Butanediol (molecular weight 90)

80.28(0.892)

Hydroxyethyl Acrylate (Molecular Weight 116)

17.28(0.149=1 / 7×1.041)

Dodecyl ammonia (molecular weight 185)

27.57(0.149=1 / 7×1.041)

total

300g

[0071] Explanation: In Table 7, the molar ratio of hexamethylene diisocyanate to propylene glycol is 1.041:0.892, which is equivalent to 7:6, that is, n=7;

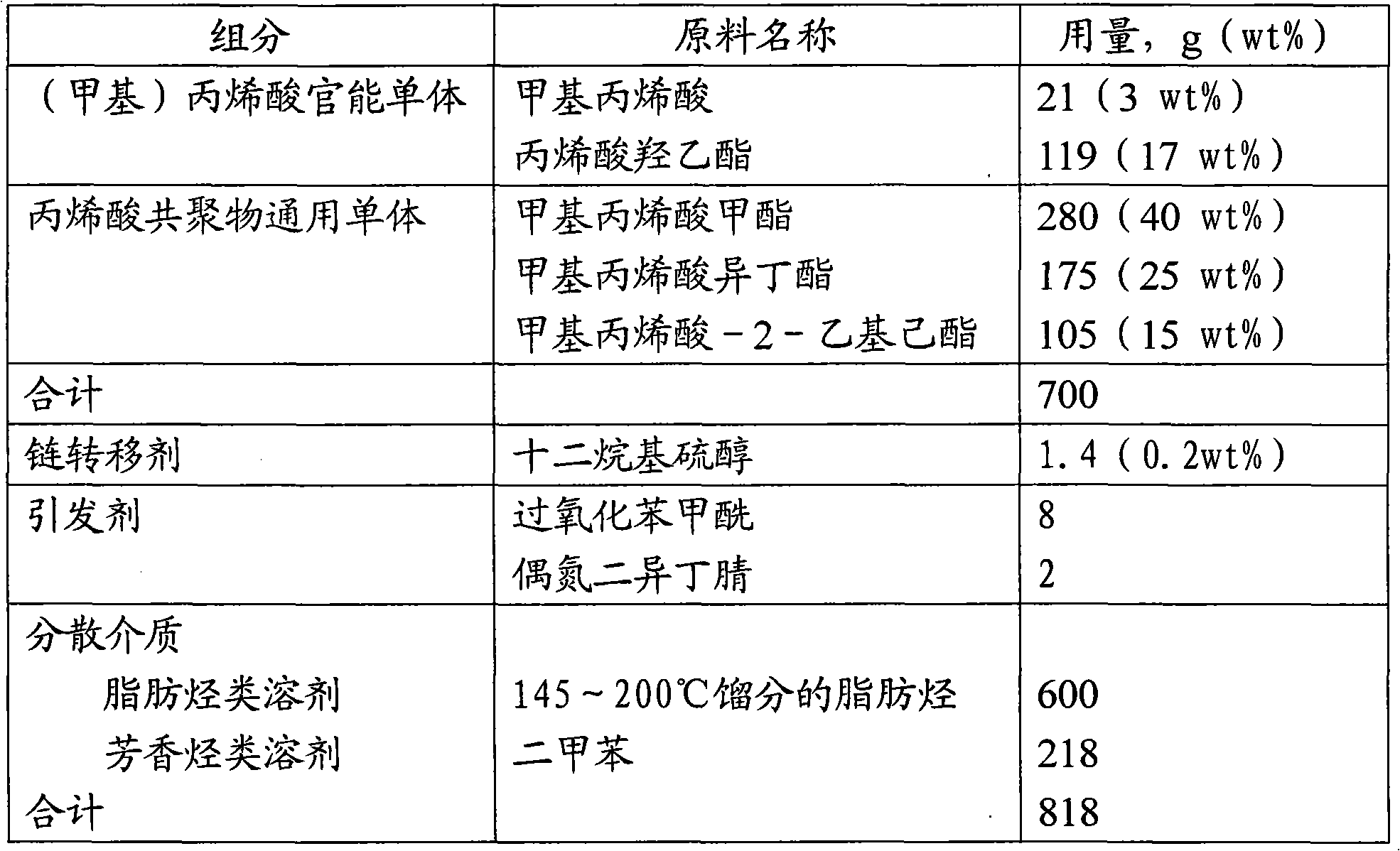

[0072] All the other raw material formulations for the synthesis of dispersion stabiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com