Magneto-plumbite type permanent magnetic ferrite and manufacturing method thereof

A technology of permanent magnet ferrite and magnetoplumbite, applied in the field of permanent magnet ferrite and its manufacture, can solve the problem of low magnetic performance, and achieve the effects of improving magnetic performance, increasing utilization rate and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

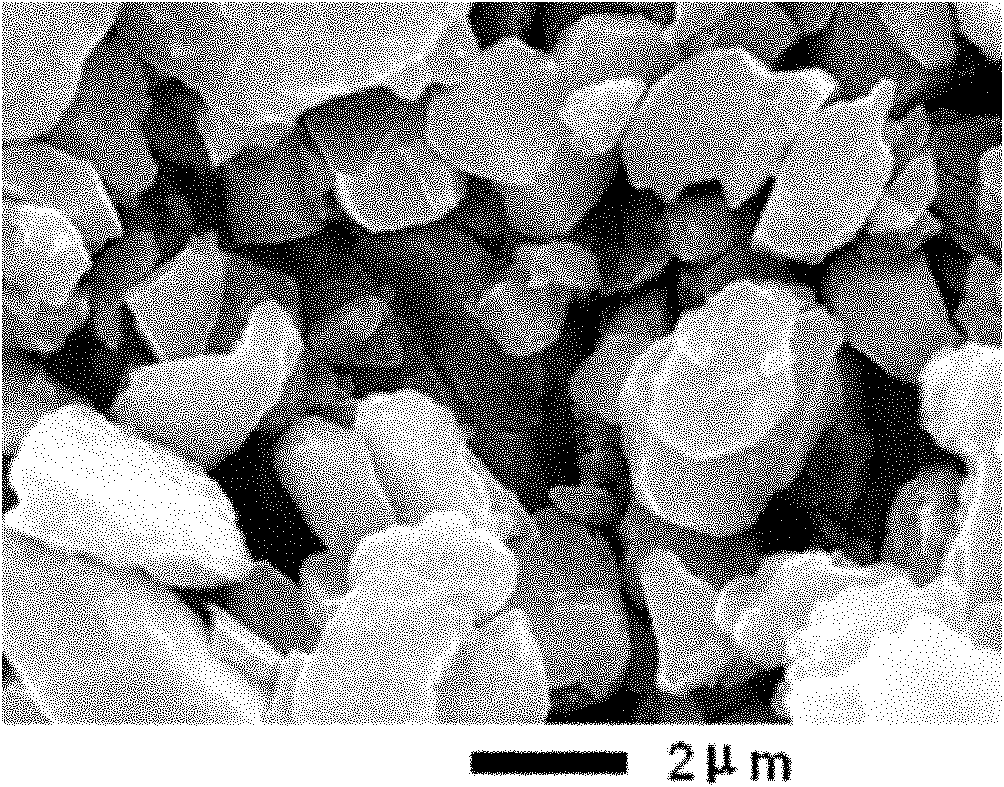

Image

Examples

Embodiment 1

[0050] Iron scale (mass percentage: TFe≥73%, FeO≥38%, MnO≤0.2%, SiO 2 ≤0.1%, S≤0.1%), after being ground to an average particle size of 1.5μm, the powder after oxidation treatment in an oxidation kiln at 880°C for 1.5 hours is Fe as its main component 2 o 3 , and prepare SrCO with a mass fraction of more than 98% 3 Powder, more than 98.5% CaCO 3 Powder, more than 99% La 2 o 3 Powder, cobalt oxide powder with a mass fraction of Co of more than 72%; secondary component Sr m m p B z o m+p+2z Preparation: take m=0.9, p=2.7, z=0.3, mix them uniformly by dry or wet method, keep warm at 950°C in air for 2 hours, and then finely pulverize to a powder with an average particle size of 1.5μm.

[0051] The principal component of the material, (Ca0) X ·(R 2 o 3 ) Y ·(Fe 2 o 3 ) n , wherein x=0.4, y=0.55, and n is 5.9 to calculate the addition amount of each main raw material. And be 2.3% by weighing the Sr by the mass fraction of the calcined material to be generated m m ...

Embodiment 2

[0054] Subcomponent Sr as a material m m p B z o m+p+2z , added in the finely pulverized stage after pre-burning, the others are the same as in Example 1, and the magnetic properties of the prepared samples are shown in Table 1.

Embodiment 3

[0056] Subcomponent Sr as a material m m p B z o m+p+2z , added directly in the mixing stage before pre-burning, kept in air at 950°C for 2 hours, and then raised to 1295°C for 2 hours. The rest are the same as in Example 1, and the magnetic properties of the prepared samples are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com