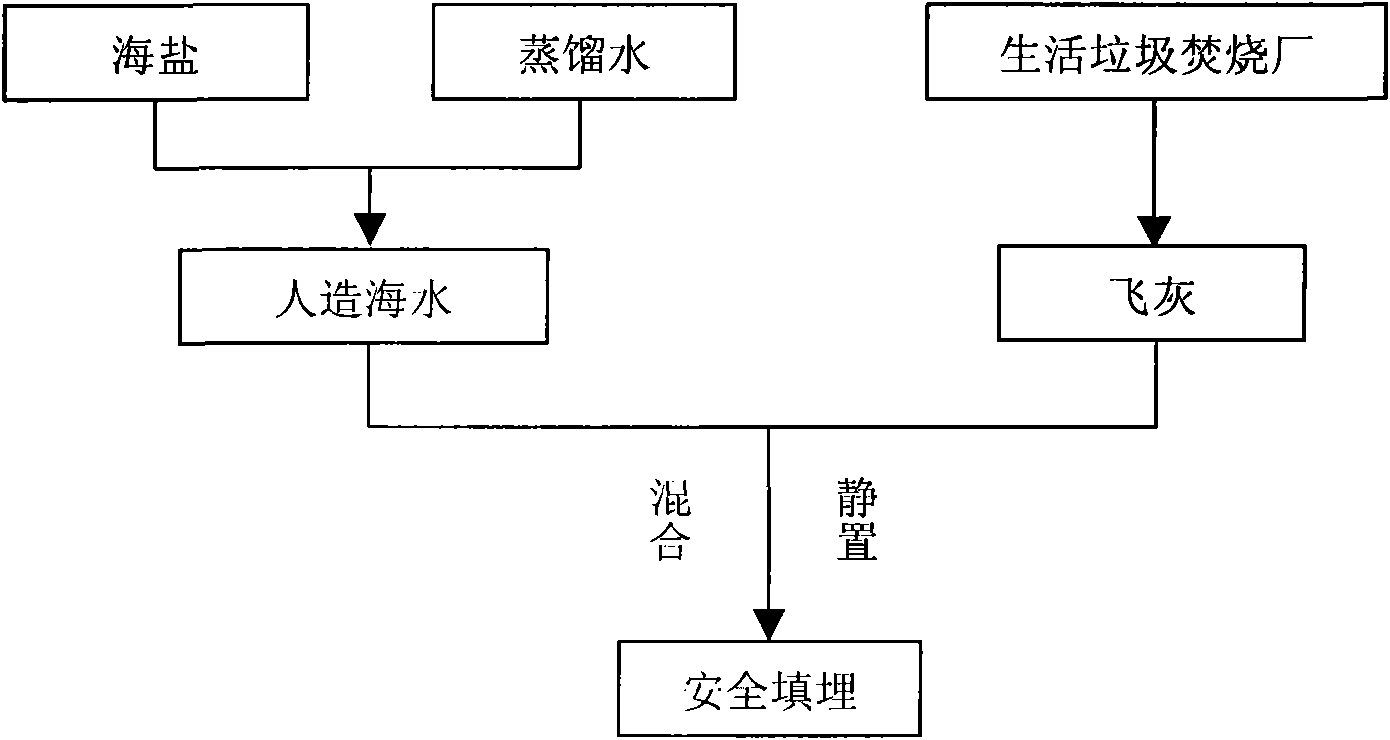

Method for stabilizing fly ash of municipal solid waste incinerator by using artificial sea water

A technology of domestic waste incineration and artificial seawater, applied in the direction of solid waste removal, etc., can solve the problem of high cost, and achieve the effect of simple operation and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

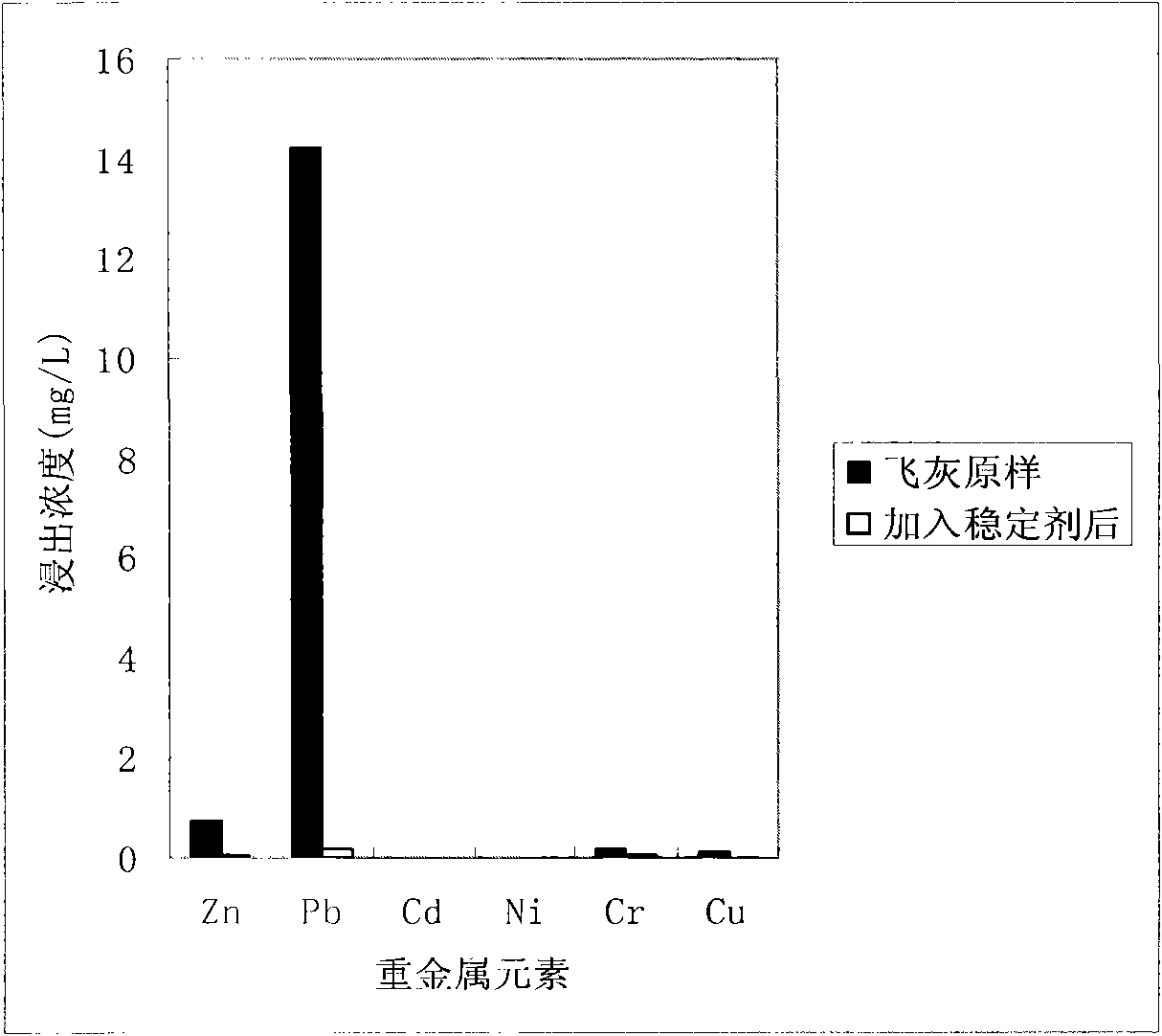

[0027] Take 100g of the above-mentioned fly ash as a sample, take 100ml of the above-mentioned stabilizer (artificial seawater), add the stabilizer to the fly ash, and stir for 10 minutes to fully mix the stabilizer solution with the fly ash to form a thick mortar substance, and the heavy metal in the fly ash The ions react completely with the stabilizer solution, and then the above mixture is dried under natural ventilation conditions, and then it can be landfilled in a hazardous waste landfill. According to the hazardous waste identification standard (GB5086.2-1997), the toxic leaching test was carried out on the treated fly ash, and the results were as follows: figure 2 Shown: show that the leaching concentration of the exceeding standard element lead (lead=14.23mg / L) is 0.21mg / L, the rest, the concentration of zinc is 0.10mg / L, the concentration of chromium is 0.03mg / L, cadmium, nickel, copper None of them were detected, reaching the pollution control standard of hazardou...

Embodiment 2

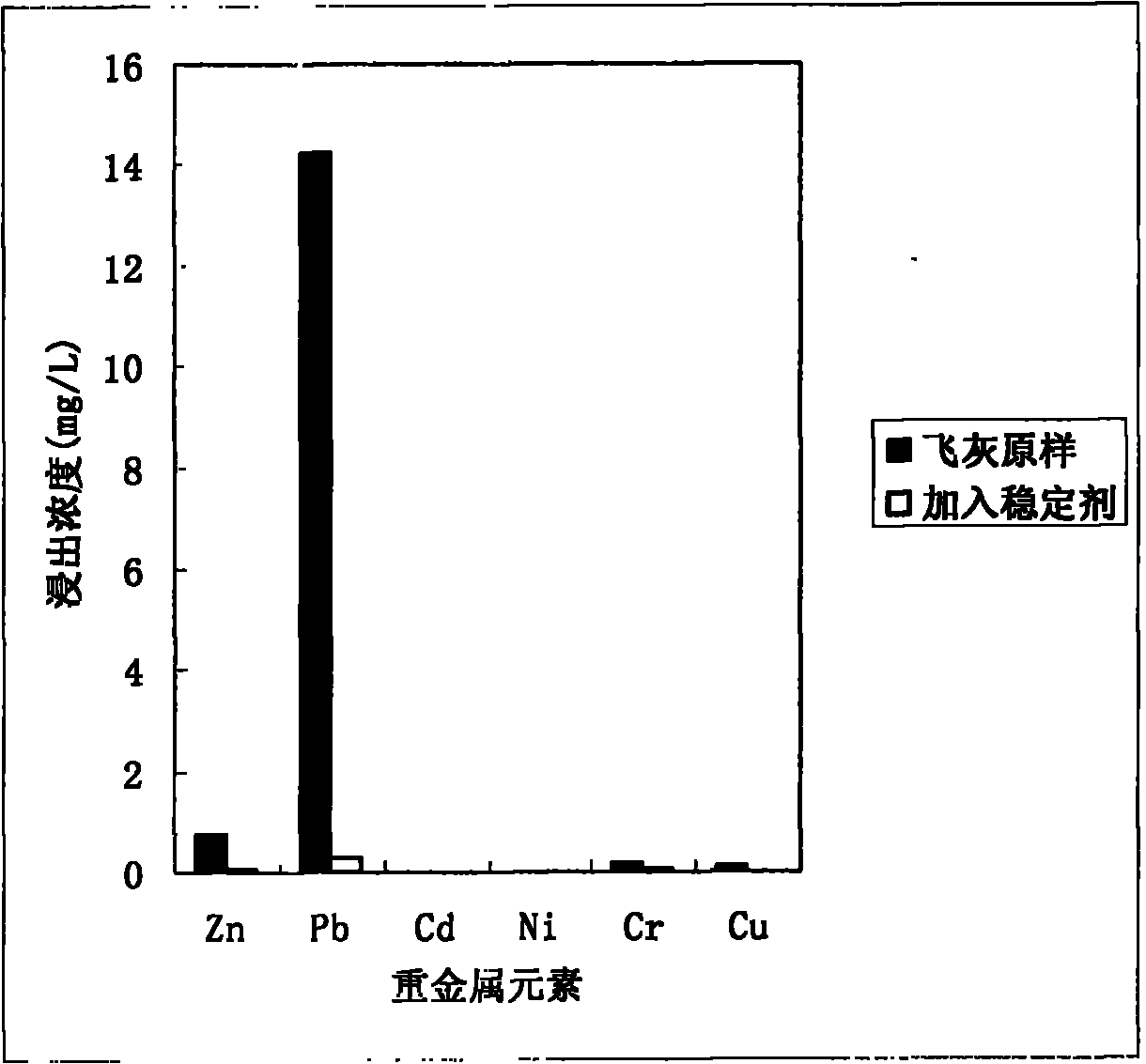

[0029] Get fly ash sample 100g, stabilizer 50ml, fly ash and stabilizer are identical with embodiment 1. Add the stabilizer to the fly ash and stir for 20 minutes to make the stabilizer and fly ash fully mixed to form a thick substance. The heavy metal ions in the fly ash react with the stabilizer solution completely, and then the above mixture is dried under natural ventilation. can enter the hazardous waste landfill. According to the hazardous waste identification standard (GB5086.2-1997), the fly ash after the treatment was carried out the toxicity leaching test, the result showed that the leaching concentration of lead exceeding the standard was 0.15mg / L, and the concentration of the rest, zinc was 0.06mg / L, The concentration of chromium is 0.035mg / L, and cadmium, nickel and copper are not detected, reaching the pollution control standard of hazardous waste landfill (GB18598-2001). Such as image 3 shown.

Embodiment 3

[0031] Take 100g of fly ash sample, 25ml of stabilizer, add the stabilizer into the fly ash, stir for 30min, make the stabilizer and fly ash fully mixed to form a thick substance, the heavy metal ions in the fly ash react completely with the stabilizer solution, and then The above-mentioned mixture is dried under the condition of natural ventilation, and can enter the hazardous waste landfill for landfilling. According to the hazardous waste identification standard (GB5086.2-1997), the fly ash after the treatment was carried out the toxicity leaching test, the result showed that the leaching concentration of lead exceeding the standard was 0.29mg / L, and the concentration of the rest, zinc was 0.045mg / L, The concentration of chromium is 0.08mg / L, and cadmium, nickel and copper are not detected, reaching the pollution control standard of hazardous waste landfill (GB18598-2001). Such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com