Method for preparing single polyelectrolyte microcapsule based on ferrocene hydrophobic interaction

A hydrophobic interaction, polyelectrolyte technology, applied in the field of preparing hollow microcapsules, can solve the problems of waste of raw materials, limited promotion and application, and many steps, and achieve the effects of enhanced permeability, wide material sources, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

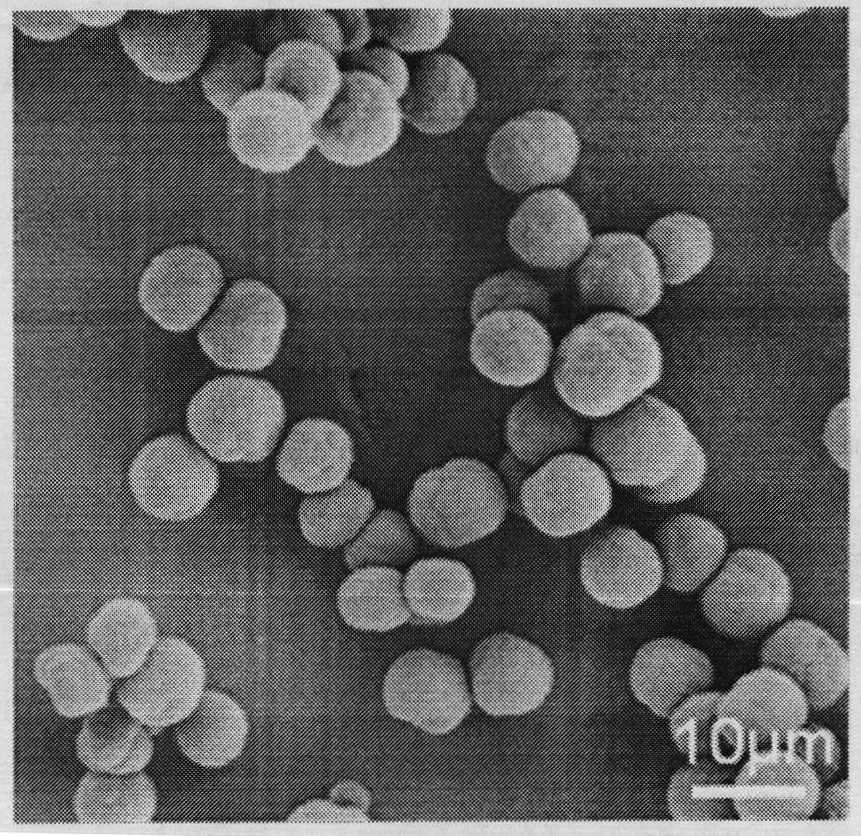

[0023] 1) Ca(NO 3 ) 2 and Na 2 CO 3 To make 0.33M aqueous solution respectively, take 100mL Ca(NO 3 ) 2 Add PAH to the solution, PAH is in Ca(NO 3 ) 2 The concentration in the solution is 2mg / mL, stir to make it evenly mixed; quickly add 100mL Na 2 CO 3 Aqueous solution, keep stirring for 40 seconds, and then let it stand to react until all the generated particles are completely precipitated; the obtained particles are collected by centrifugation, washed 3 times with water, and CaCO with a diameter of about 5.5 microns is obtained. 3 Particles, whose scanning electron microscope pictures are shown in figure 1 ; this CaCO 3 The microparticles are templates for colloidal particles doped with PAH.

[0024] 2) The CaCO doped with PAH obtained in step 1) 3 Put the microparticles into 20 mL of ferrocene formaldehyde methanol solution with a concentration of 20 mg / mL, shake to form a suspension, and keep shaking for 3 hours to react the amino group of PAH with the Schiff b...

Embodiment 2

[0027] 1) Ca(NO 3 ) 2 and Na 2 CO 3 To make 0.33M aqueous solution respectively, take 70mL Ca(NO 3 ) 2 Add PAH to the solution, PAH is in Ca(NO 3 ) 2 The concentration in the solution is 5mg / mL, stir to make it evenly mixed; quickly add 70mL Na 2 CO 3 Aqueous solution, keep stirring for 50 seconds, and then let it stand to react until all the generated particles are completely precipitated; the obtained particles are collected by centrifugation, washed 3 times with water, and colloidal CaCO doped with PAH is obtained 3 particle.

[0028] 2) The CaCO doped with PAH obtained in step 1) 3 Put the microparticles into 30 mL of ferrocene formaldehyde methanol solution with a concentration of 10 mg / mL, shake to form a suspension, and keep shaking for 4 hours to react the amino group of PAH with the Schiff base of ferrocene formaldehyde. Then centrifuge, wash and disperse the colloidal particles with ethanol; add excess NaBH to the ethanol suspension of the colloidal particl...

Embodiment 3

[0031] 1) Ca(NO 3 ) 2 and Na 2 CO 3 To make 0.33M aqueous solution respectively, take 50mL Ca(NO 3 ) 2 Add PAH to the solution, PAH is in Ca(NO 3 ) 2 The concentration in the solution is 10mg / mL, stir to make it evenly mixed; quickly add 50mL Na 2 CO 3 Aqueous solution, keep stirring for 60 seconds, and then let it stand for reaction until all the generated particles are completely precipitated; the obtained particles are collected by centrifugation and washed 3 times with water to obtain colloidal CaCO doped with PAH 3 particle.

[0032] 2) The CaCO doped with PAH obtained in step 1) 3 Put the microparticles into 20 mL of ferrocene formaldehyde methanol solution with a concentration of 30 mg / mL, shake to form a suspension, and keep shaking for 4 hours to react the amino group of PAH with the Schiff base of ferrocene formaldehyde. Then centrifuge, wash and disperse the colloidal particles with ethanol; add excess NaBH to the ethanol suspension of the colloidal partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com