Coal distributing system and coal feeder used in same

A technology of coal blending system and coal feeder, applied in mixers, mixer accessories, dissolving and other directions, can solve the problems of inability to realize coal blending operation and simple structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention clearer, the best implementation modes of the present invention will be further described in detail below in conjunction with the accompanying drawings.

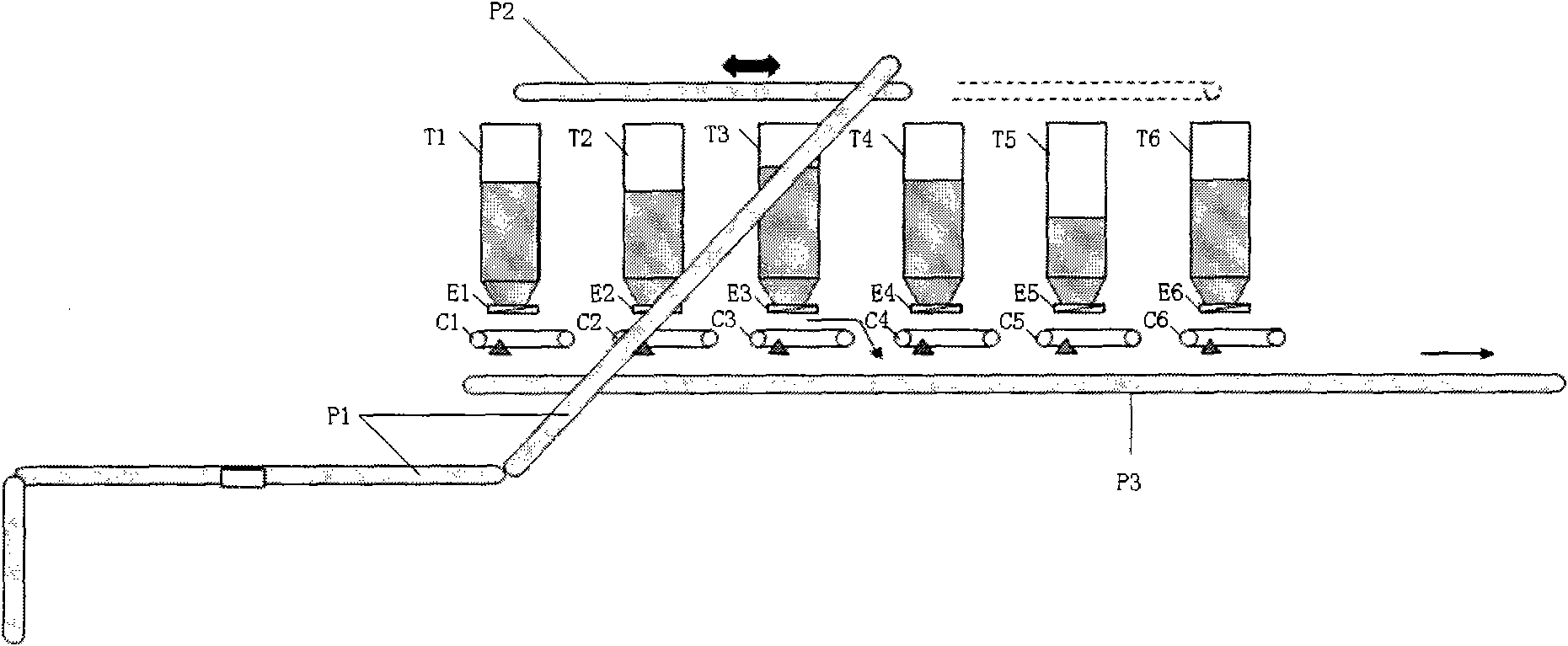

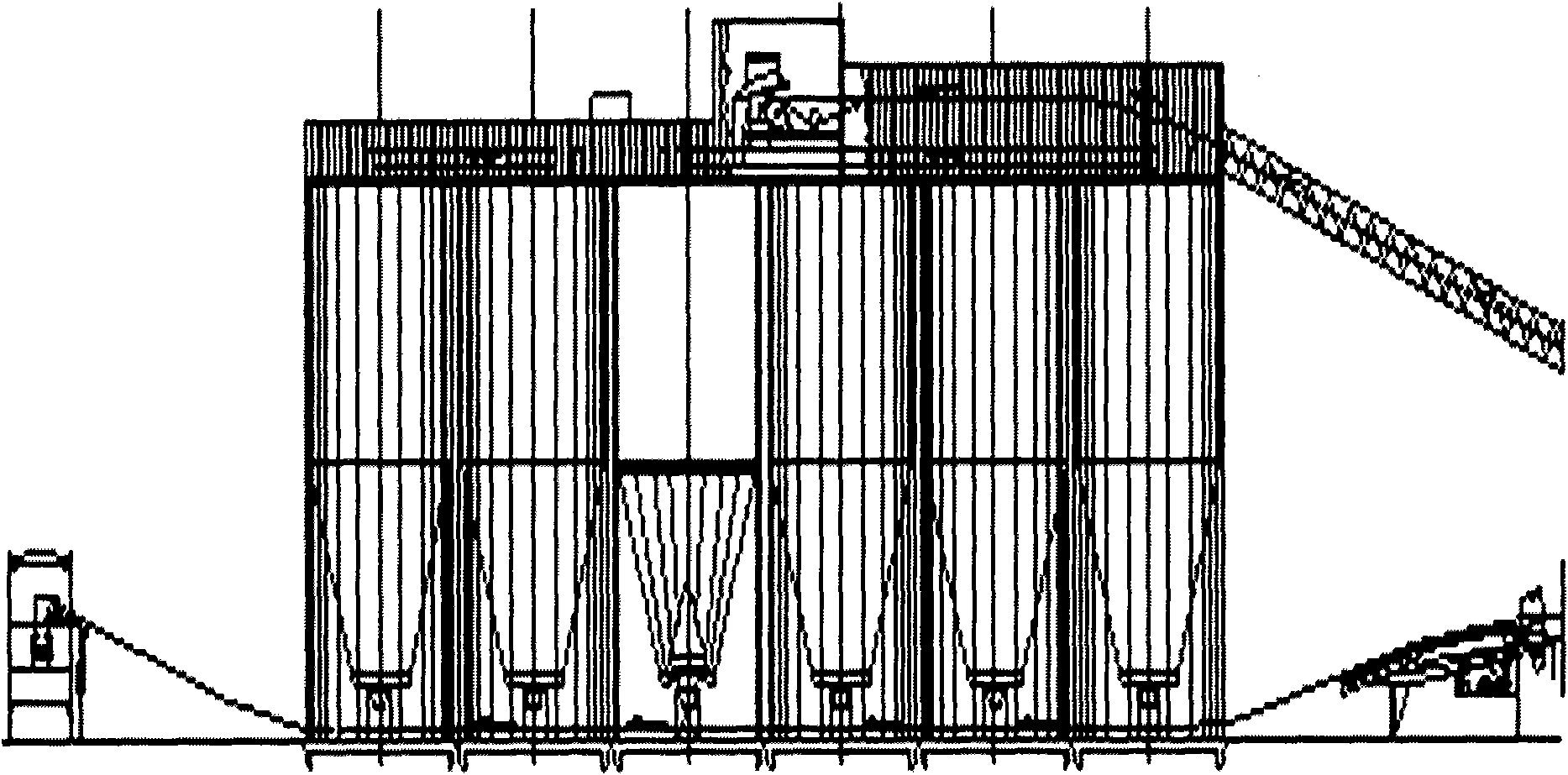

[0021] First, refer to figure 2 The overall structure of the coal blending system involved in the present invention is introduced in detail. As shown in the figure, the coal blending system includes six raw coal silos T1-T6 arranged side by side, and each raw coal silo T1-T6 is filled with one kind of raw coal. Above the six raw coal silos T1-T6, there is a second raw coal conveyor belt P2 that can move horizontally with a reversible trolley not shown in the figure, and one end of the second raw coal conveyor belt P2 is connected to a storage tank for stacking on the ground. Various raw coals are lifted and transported to the first raw coal conveyor belt P1 on the second raw coal conveyor belt P2. The reversible trolley is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com