Rectification and recovery system of alcohol with high purity

A recovery system and high-purity technology are applied in the field of high-purity alcohol rectification recovery systems to achieve the effects of reasonable method and design, simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

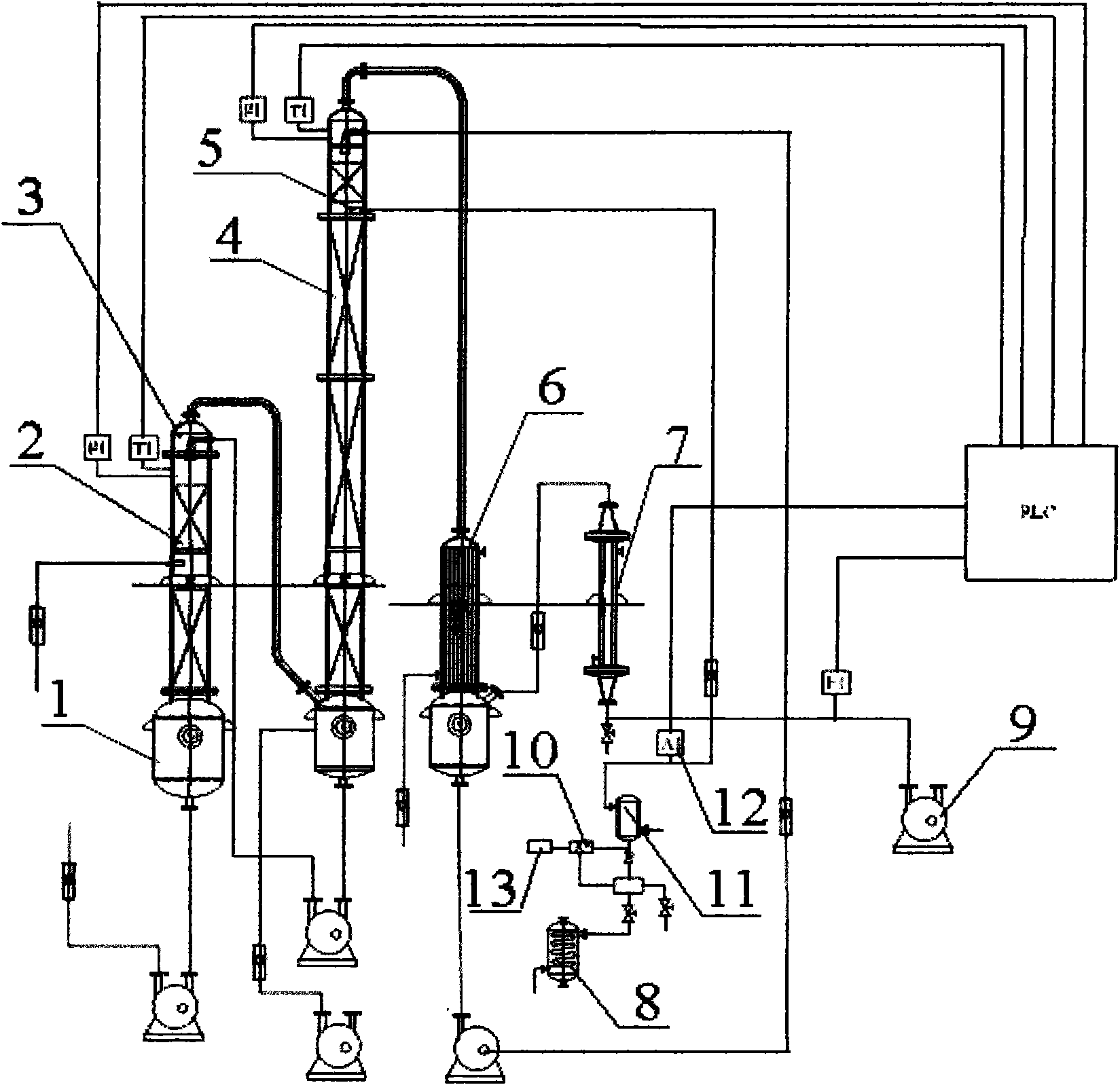

Method used

Image

Examples

Embodiment 1

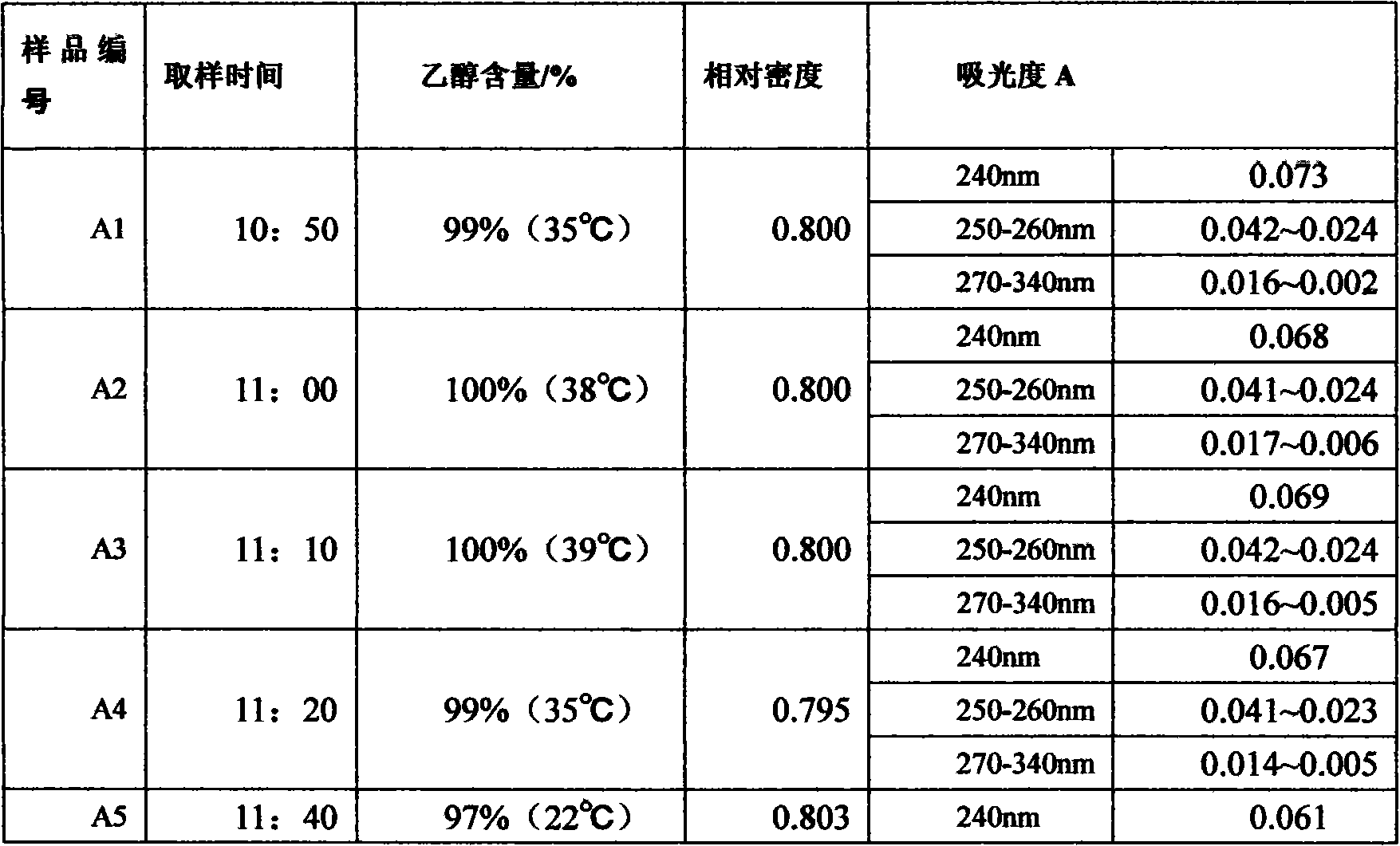

[0020] Investigate the effect of tail gas suction on rectification effect, The untreated dilute alcohol is pumped into the distillation kettle, the minimum must not be lower than the steam heating pipe in the kettle, and the highest must not exceed the tower kettle 2 / 3 of the diameter, open the condenser and cooler water inlet valves, and confirm that there is water flowing normally, Fully open the return valve, then turn on the tail gas suction pump, and open the steam valve for heating. During the implementation process, instrument parameters such as start-up time, feed time, stabilization time, tower top temperature, condensation outlet temperature, and condenser return water temperature were recorded. The results are shown in Table 1. A total of six samples were taken from one sample, and the sample numbers were A1, A2, A3, A4, and A5. The ethanol content, relative density, and absorbance were measured respectively, and the experimental data were recorded. The experime...

Embodiment 2

[0025] Investigate the influence of tail gas suction speed on rectification effect, The untreated dilute alcohol is pumped into the distillation kettle, the minimum must not be lower than the steam heating pipe in the kettle, and the highest must not exceed the tower kettle 2 / 3 of the diameter, open the condenser and cooler water inlet valves, and confirm that there is water flowing normally, Fully open the return valve, then open the steam valve for heating. The specific implementation steps are the same as in Example 1. In the implementation process, when the concentration of the finished product meets the requirements, the first sample is taken, and one sample is taken per hour later. The first three samples (the tail gas flow rate is 0.8m 3 / h) Adjust the tail gas flow rate after taking, and still take one sample per hour (the tail gas flow rate is 0.5m 3 / h), the sample numbers are respectively B1, B2, B3, B4, B5, B6, B7, measure its ethanol content, relative density...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com