Foam carbon biological support, and preparation method and application thereof

A bio-scaffold and carbon foam technology, applied in animal cells, vertebrate cells, medical science, etc., can solve the problem of degradability, absorbability, low compressive strength, high density of cells in vitro, and long-term culture of scaffolds Material and other issues, to achieve long-term stable mechanical strength, high activity three-dimensional culture, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

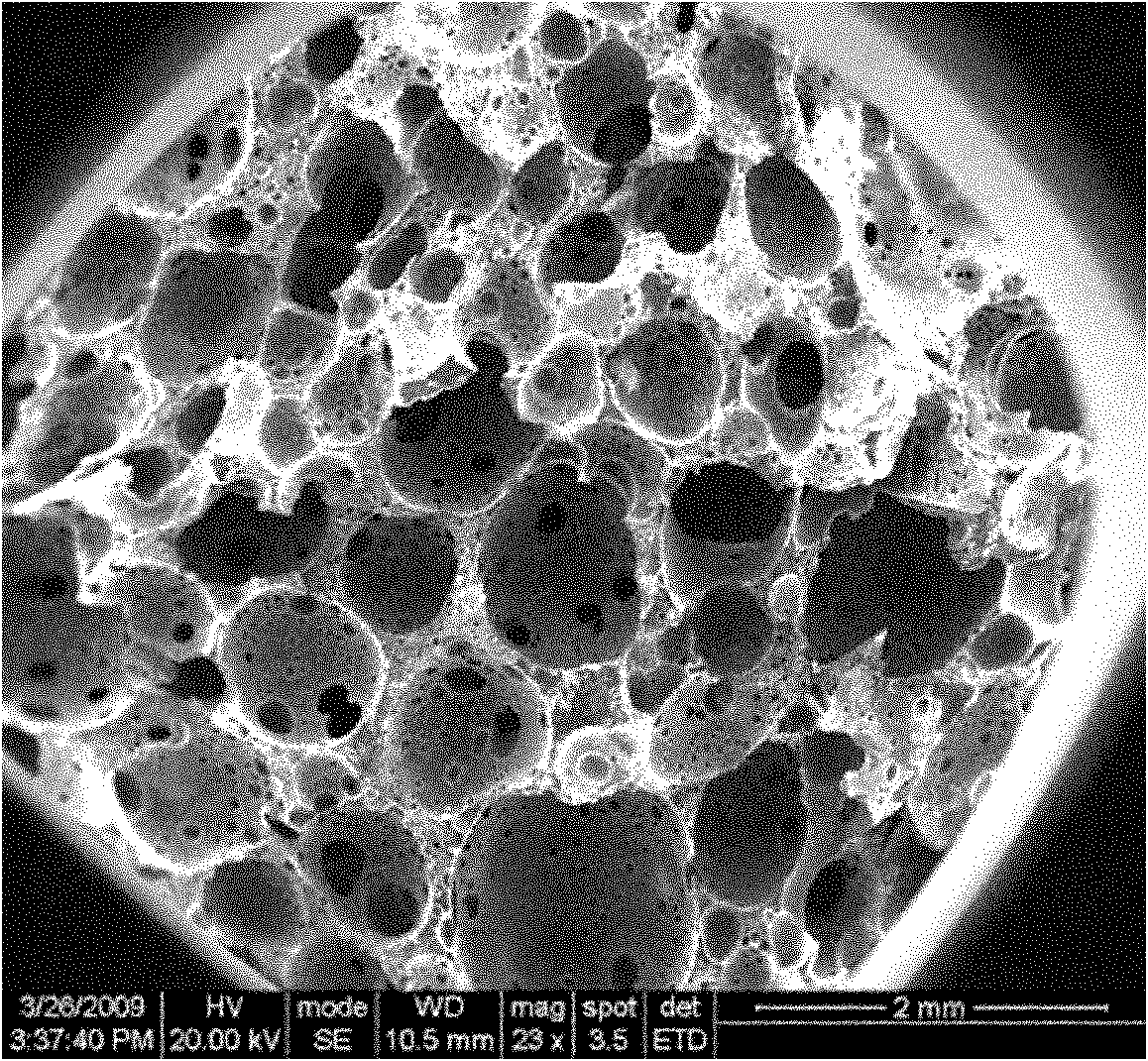

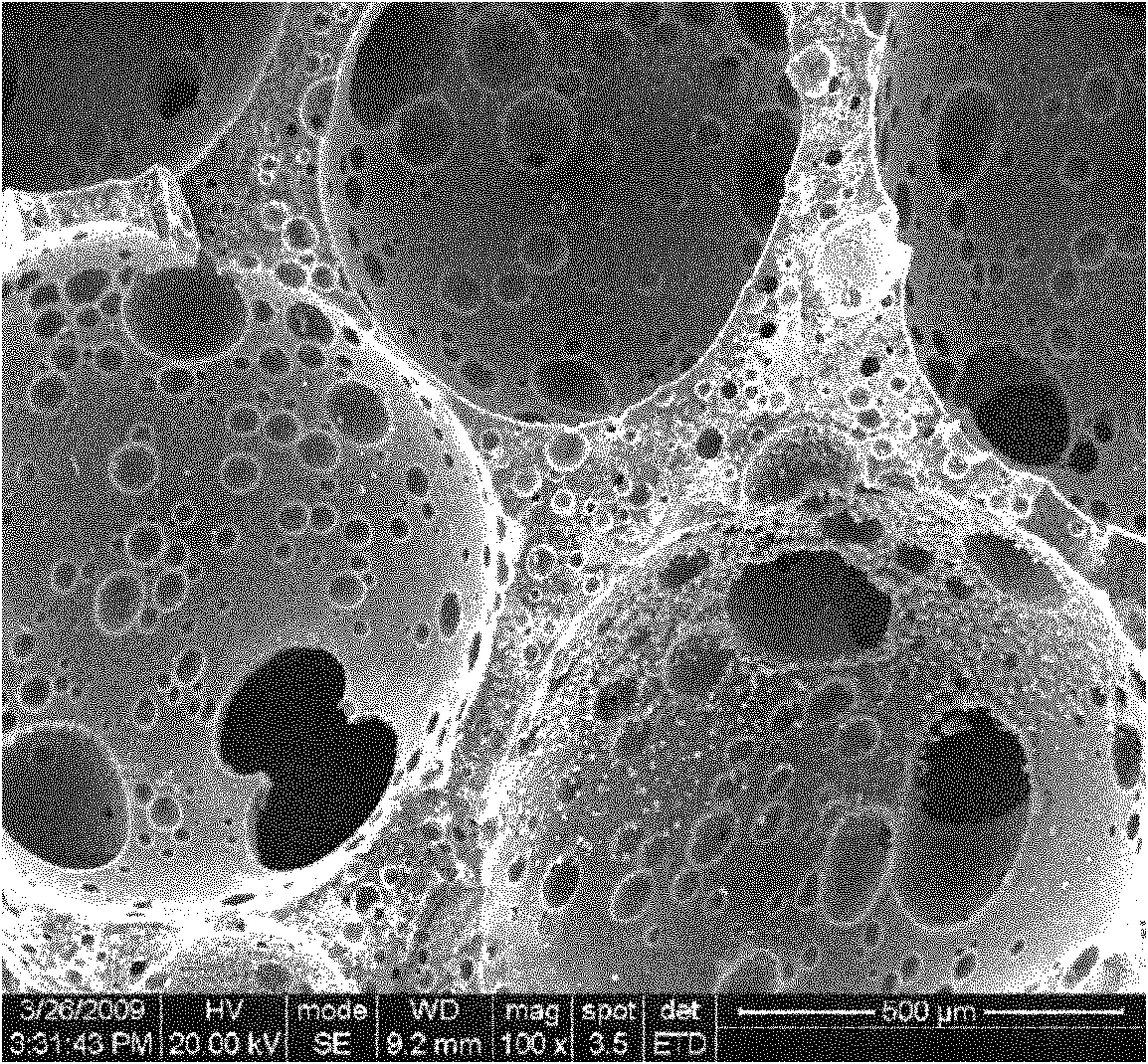

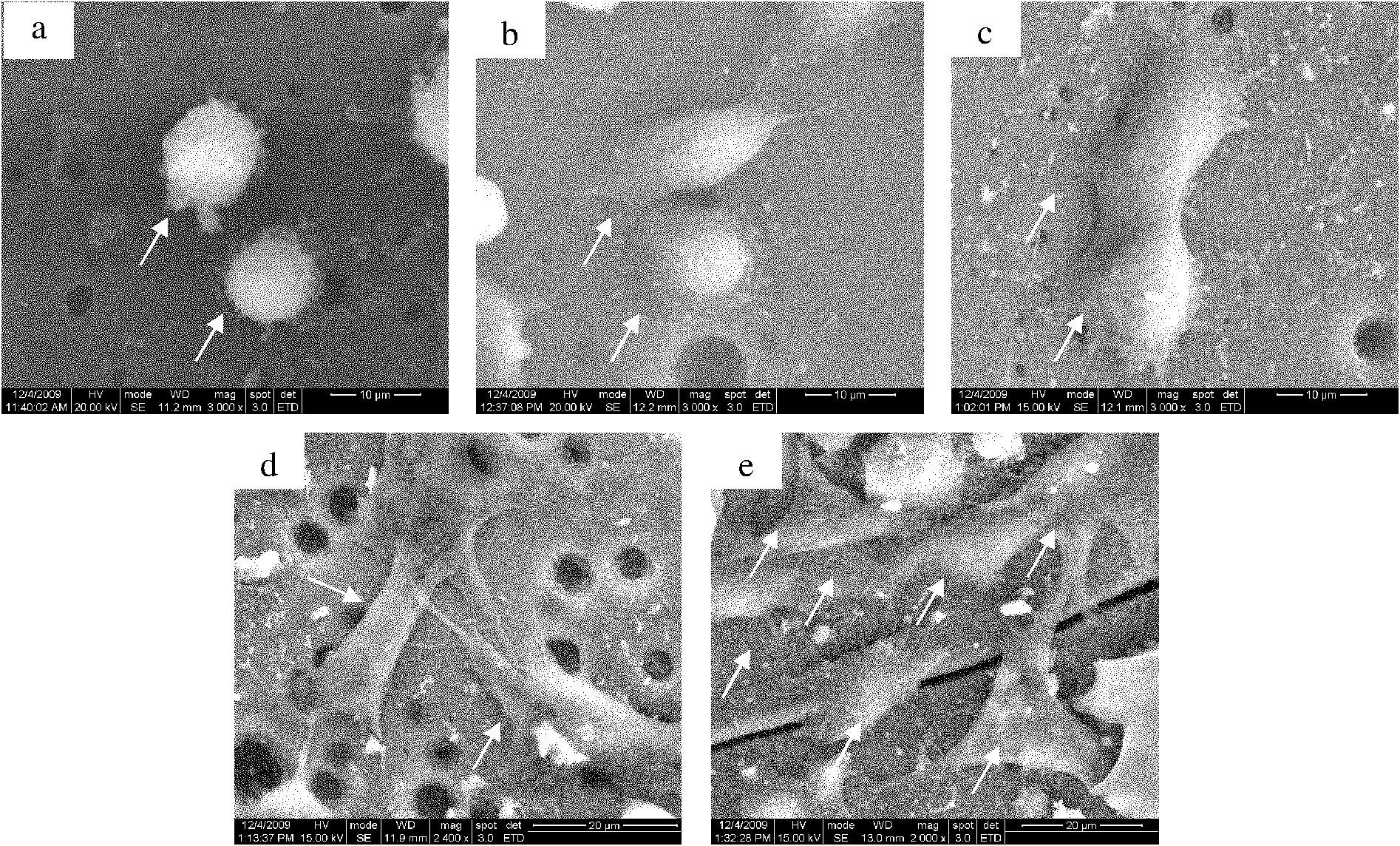

[0023] a kind of like Figure 1 ~ Figure 2 The foamed charcoal bioscaffold of the present invention is shown, the foamed charcoal bioscaffold is formed by carbonization of the precursor formed by phenolic resin, and the precursor is formed by foaming and curing the phenolic resin under normal pressure. The carbon foam bio-stent of this embodiment has a three-dimensional interconnected pore structure, the diameter of the interconnected pores is about 220 microns, and the opening ratio is 80±2%.

[0024] The preparation method of the foamed charcoal bioscaffold of the present embodiment mainly includes the following steps:

[0025] (1) Batching: get 100 parts of phenolic resins (adopted in the present embodiment is 2130 brand phenolic resins), first add 30 parts of foaming agent n-pentane, then add 0.5 parts of emulsifying agent cetyl Sodium benzenesulfonate and 0.9 parts of filler graphite powder (graphite powder crosses 200 mesh sieves), stir and mix to obtain resin mixture; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com