Tool for rotary cutting machining

A technology for cutting and cutting tools, which is applied in the field of replaceable cutting heads, tool bodies and cutting heads, and can solve the problems of high surface tolerance requirements and troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

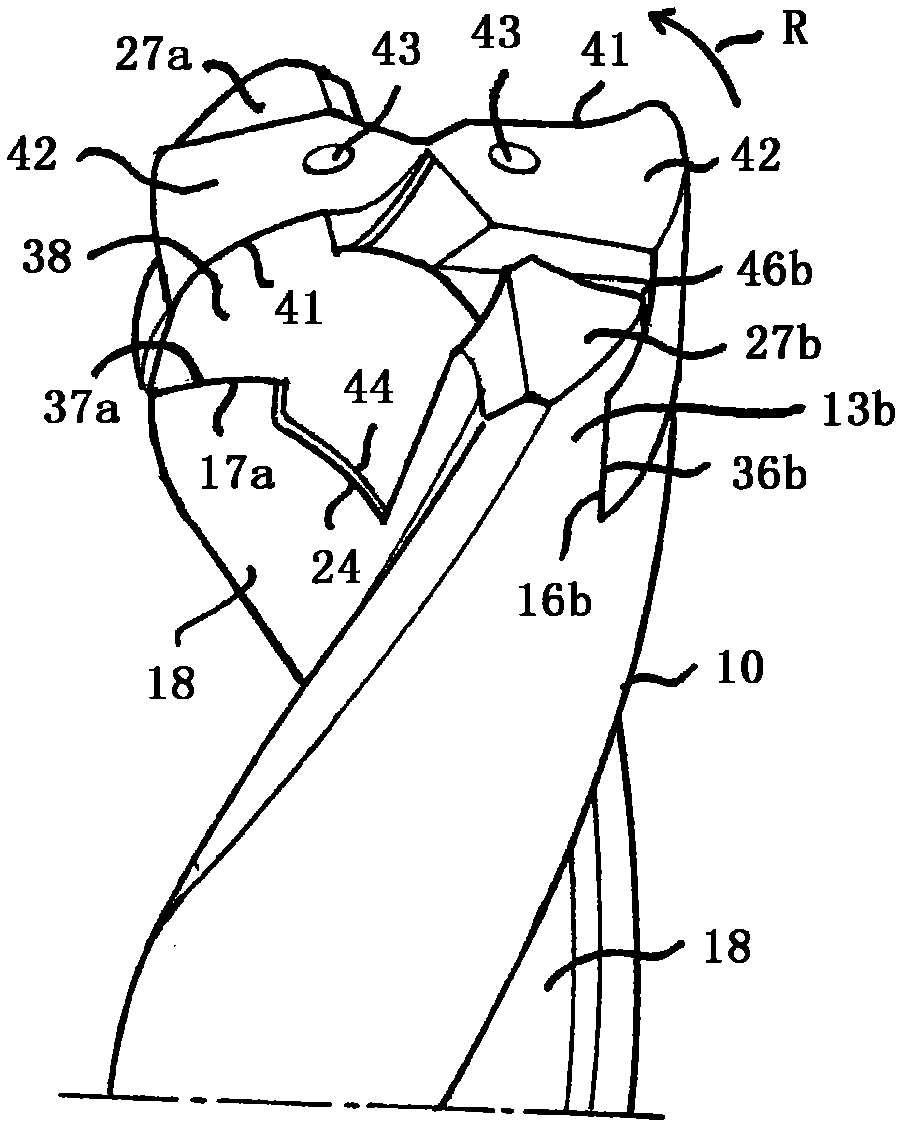

[0029] The tool 1 of the present invention is intended to rotate, for the machining of workpieces. In the example shown, the tool is designed as an auger, but it is also possible to design the tool according to the invention as another tool for rotary cutting machining, for example a milling cutter or the like.

[0030] The intended direction of rotation of tool 1 for machining is in figure 2 , Figure 4 as well as Figure 11-12 Marked by arrow R. This direction of rotation is hereinafter named "rotary machining direction" and thus constitutes the direction of rotation in which the tool rotates for cutting machining of workpieces, preferably metal. Alternatively, the workpiece can be rotated while the tool remains stationary.

[0031] The tool 1 comprises a tool body 10 and a replaceable cutting head 30 detachably attachable to the tool body.

[0032] The cutting head 30 is formed in one piece of suitable cemented carbide, ie made of pressed or injection molded cemented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com