Manufacturing method for planetary support of electric power tool gear box

A technology for planetary brackets and electric tools, which is applied to belts/chains/gears, mechanical equipment, transmission parts, etc. It can solve the problems of inability to manufacture structural parts, poor assembly accuracy, and difficult processing, so as to avoid cracks, Improved torsional performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

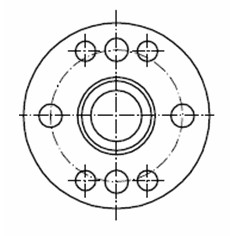

Image

Examples

Embodiment 1

[0025] The ingredient weight composition of the upper cover and the lower cover: 0.5%C, 3%Ni, 1.5%Mo, and the rest is Fe.

[0026] The batching weight composition of solder: 40% Ni, 40% Cu, 20% Mn.

[0027] Preparation methods include:

[0028] (1) Ingredients: Do ingredients according to the above formula.

[0029] (2) Forming: The planetary bracket of the electric tool gearbox is decomposed into two independent powder metallurgy parts: an upper cover with a flange and a lower cover with a support section, and a 60-ton powder extrusion molding machine is used to convert the powder metallurgy The component materials are formed individually by cavity extrusion. The density of the supporting legs of the lower cover reaches 6.9~7.0g / cm 3 , and ensure that there are no cracks at the root of the two supporting legs. A groove is provided on the end face of the upper cover.

[0030] (3) Pre-sintering: The upper cover and the lower cover are respectively placed in a common mesh b...

Embodiment 2

[0038] The weight composition of the top cover and the bottom cover: 1.0%C, 1.0%Ni, 0.5%Mo, and the rest is Fe.

[0039] The batch weight composition of solder: 45% Ni, 30% Cu, 25% Mn.

[0040] Preparation methods include:

[0041] (1) Ingredients: Do ingredients according to the above formula.

[0042] (2) Forming: The planetary bracket of the electric tool gearbox is decomposed into two independent powder metallurgy parts: an upper cover with a flange and a lower cover with a support section, and a 60-ton powder extrusion molding machine is used to convert the powder metallurgy The component materials are formed individually by cavity extrusion. The density of the supporting legs of the lower cover reaches 6.9~7.0g / cm 3 , and ensure that there are no cracks at the root of the two supporting legs. A groove is provided on the end face of the upper cover.

[0043] (3) Pre-sintering: The upper cover and the lower cover are respectively placed in a common mesh belt furnace a...

Embodiment 3

[0051] The weight composition of the upper cover and the lower cover: 0.2%C, 2.0%Ni, 2.0%Mo, and the rest is Fe.

[0052] The batch weight composition of solder: 30% Ni, 45% Cu, 25% Mn.

[0053] Preparation methods include:

[0054] (1) Ingredients: Do ingredients according to the above formula.

[0055] (2) Forming: The planetary bracket of the electric tool gearbox is decomposed into two independent powder metallurgy parts: an upper cover with a flange and a lower cover with a support section, and a 60-ton powder extrusion molding machine is used to convert the powder metallurgy The component materials are formed individually by cavity extrusion. The density of the supporting legs of the lower cover reaches 6.9~7.0g / cm 3 , and ensure that there are no cracks at the root of the two supporting legs. A groove is provided on the end face of the upper cover.

[0056] (3) Pre-sintering: The upper cover and the lower cover are respectively placed in a common mesh belt furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com