Self-cooling guide vane downdraft type submersible pump

A submersible pump, self-cooling technology, applied in the direction of non-variable pumps, pumps, pump devices, etc., can solve the problems of high motor temperature, high cost, complex structure, etc., achieve hydraulic efficiency improvement, low manufacturing cost, and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings.

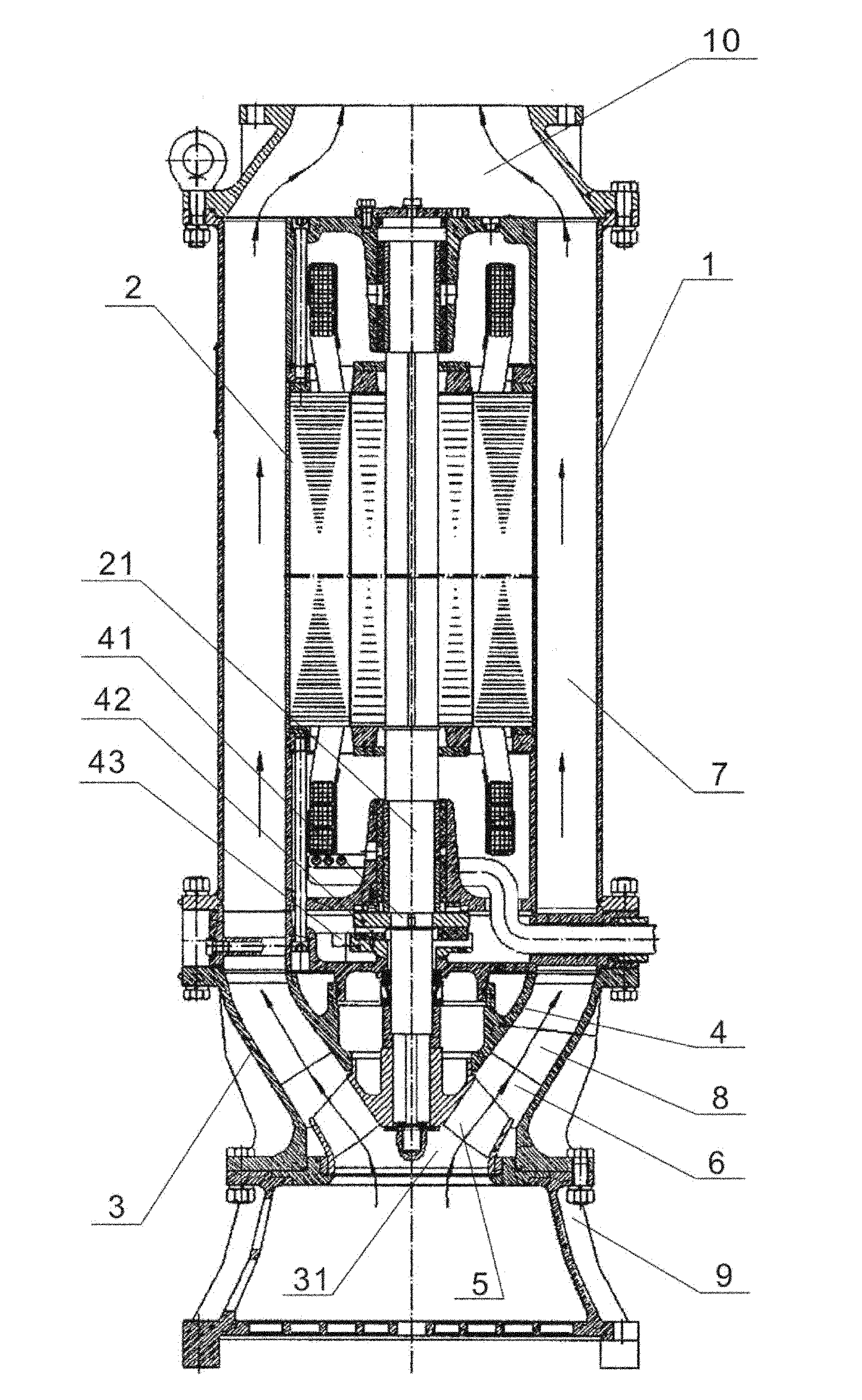

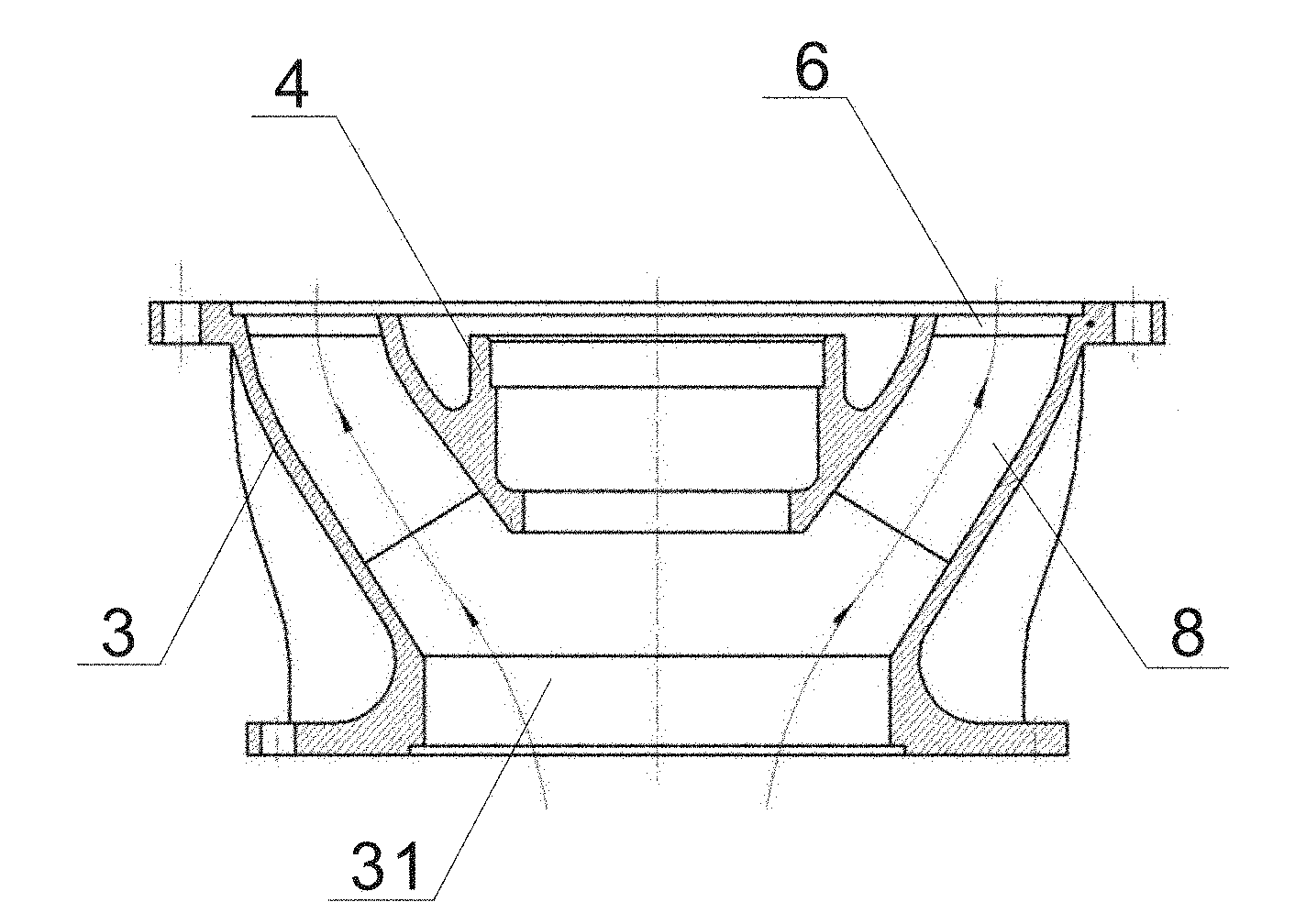

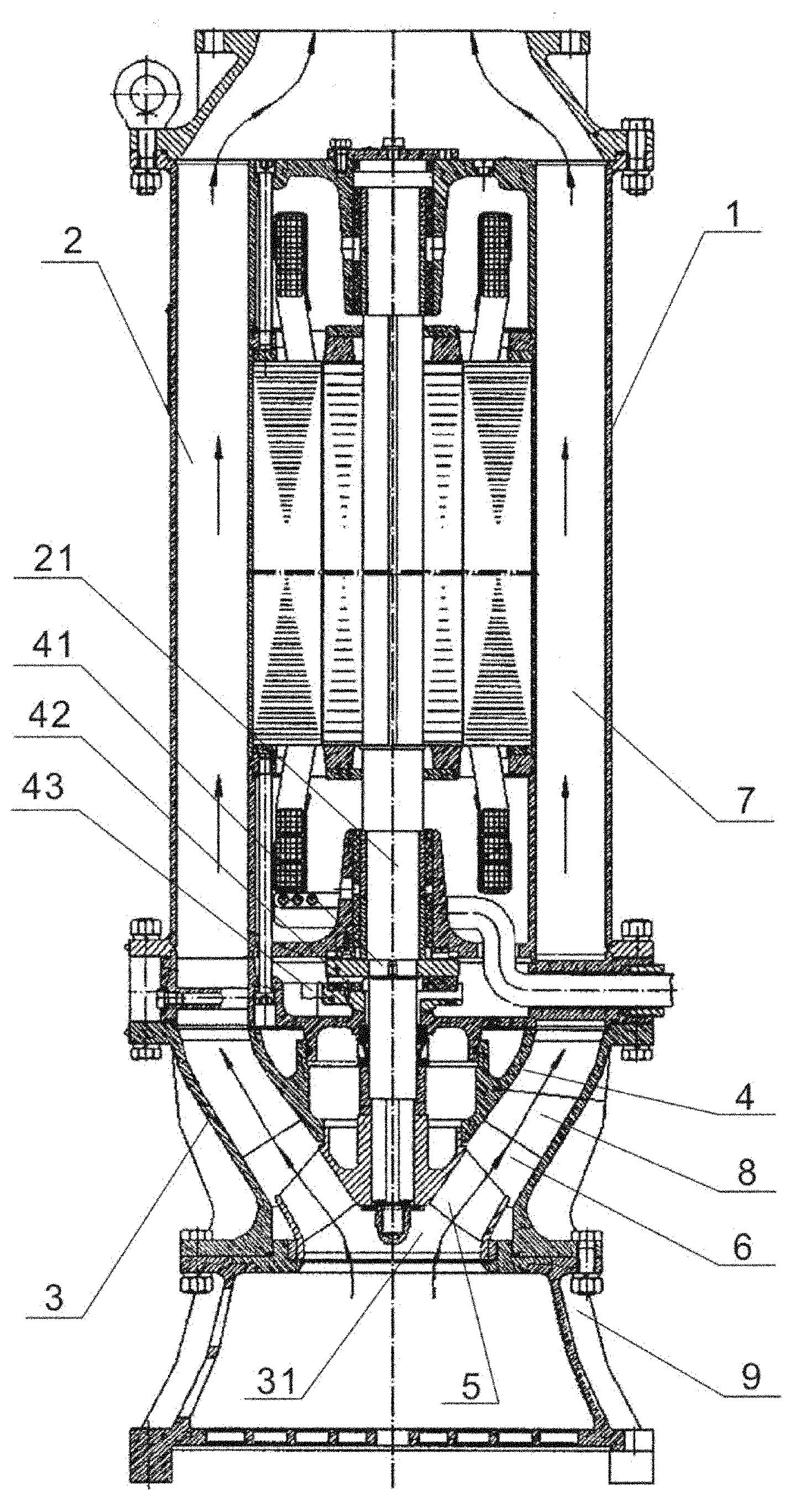

[0018] like figure 1 As shown, a self-cooling guide vane down-suction submersible pump provided by the present invention is mainly composed of a pump casing 1 and a motor 2. In order to ensure the working efficiency of the submersible pump, the motor 2 is preferably a water-filled motor, wherein The motor 2 is set inside the pump body shell 1, and then the water outlet joint 10 is set on the pump body shell 1. In addition, the submersible pump is also provided with a diversion shell 3, and the diversion shell 3 is sealed and fixed under the pump body shell 1. It The bottom of the bottom is provided with a water suction port 31 from which water can enter the submersible pump. In order to ensure that the water flow passes through the diversion shell 3 more smoothly, it is better to arrange several guide vanes 8 in the annular diversion channel 7 inside it. The water su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com