Construction method for pre-laying tunnel waterproof coiled material

A technology of waterproofing membrane and construction method, which is applied in tunnels, tunnel lining, earth-moving drilling, etc., can solve the problems of easily damaged waterproofing layer, little problem of sticking waterproofing membrane, difficult construction of waterproofing layer, etc. tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

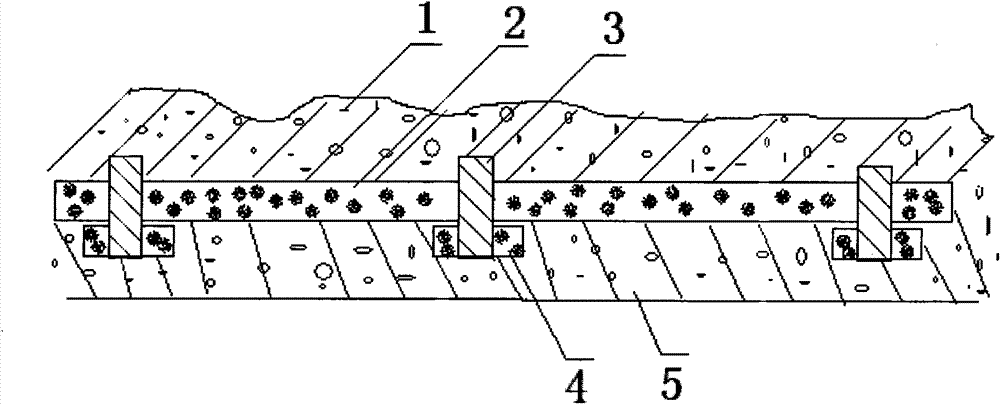

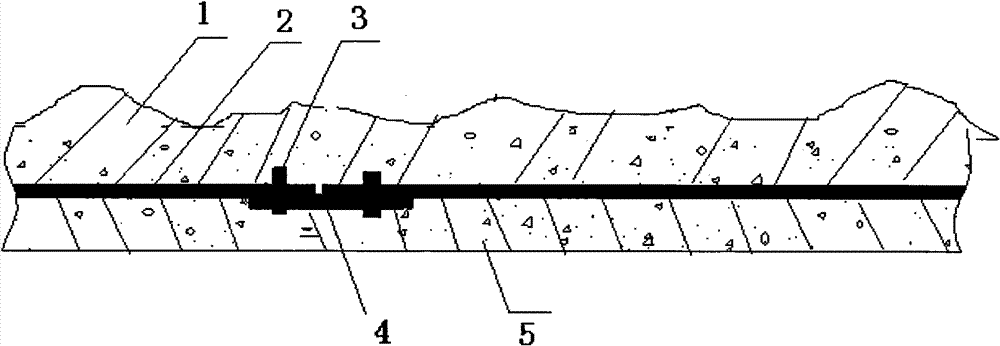

[0032] For the construction of a highway tunnel in Guangxi, a layer of concrete with a thickness of 10 cm was sprayed on the top of the tunnel, and the wet-laid pre-laid waterproof membrane was laid after the concrete dried. Each time a section (one piece) of waterproof membrane was laid, composite nailing was used The method is to fasten the waterproof coiled material on the top surface or side wall of the project. The composite nailing method is to put a small piece of gasket or gasket on the surface of the waterproof coiled material before nailing, and then The nail gun shoots nails into the waterproof membrane and the concrete layer above the gasket or gasket, so that the waterproof membrane and the concrete layer are firmly combined and difficult to separate, and then pour a layer of concrete on the surface of the waterproof membrane, and the Play a very good role in waterproof and anti-seepage.

Embodiment 2

[0034] In March 2010, the basement of an office building in Guangxi was under construction. The office building had been built for 8 years. Since the groundwater in the office building was abundant, there was water seepage in some walls of the basement. The inventor first treated the side walls and wiped them A layer of concrete with a thickness of 1-2 cm, and then lay the wet-laid pre-laid waterproof membrane. When laying a section (one piece) of waterproof membrane, the composite nailing method is used to nail the waterproof membrane to the top or side of the project. On the wall, the composite nail shooting method is to put a small piece of gasket or strip on the surface of the waterproof membrane before nailing, and then use a nail gun to shoot nails into the surface of the gasket or strip. In the waterproof membrane and the concrete layer, the waterproof membrane and the concrete layer are firmly combined and not easy to separate, and then a layer of 2 cm concrete is spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com