Graphite boat and graphite boat group for hard alloy sintering technology

A graphite boat and cemented carbide technology, which is applied in the field of tools, can solve the problems of uneven atmosphere, unstable sintered product quality, and poor removal of molding agents, and can ensure product performance, uniform atmosphere density distribution, and product composition. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

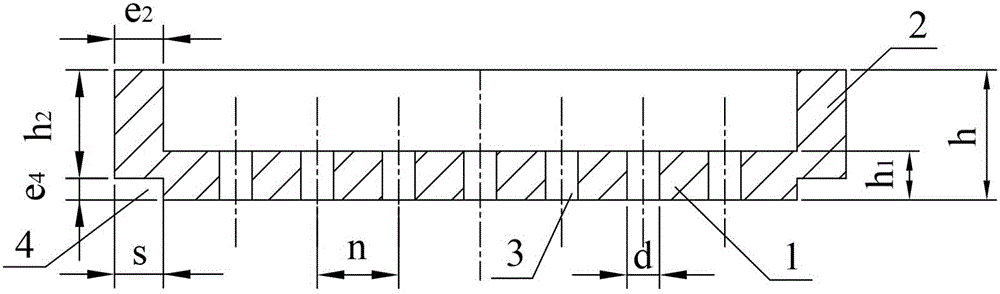

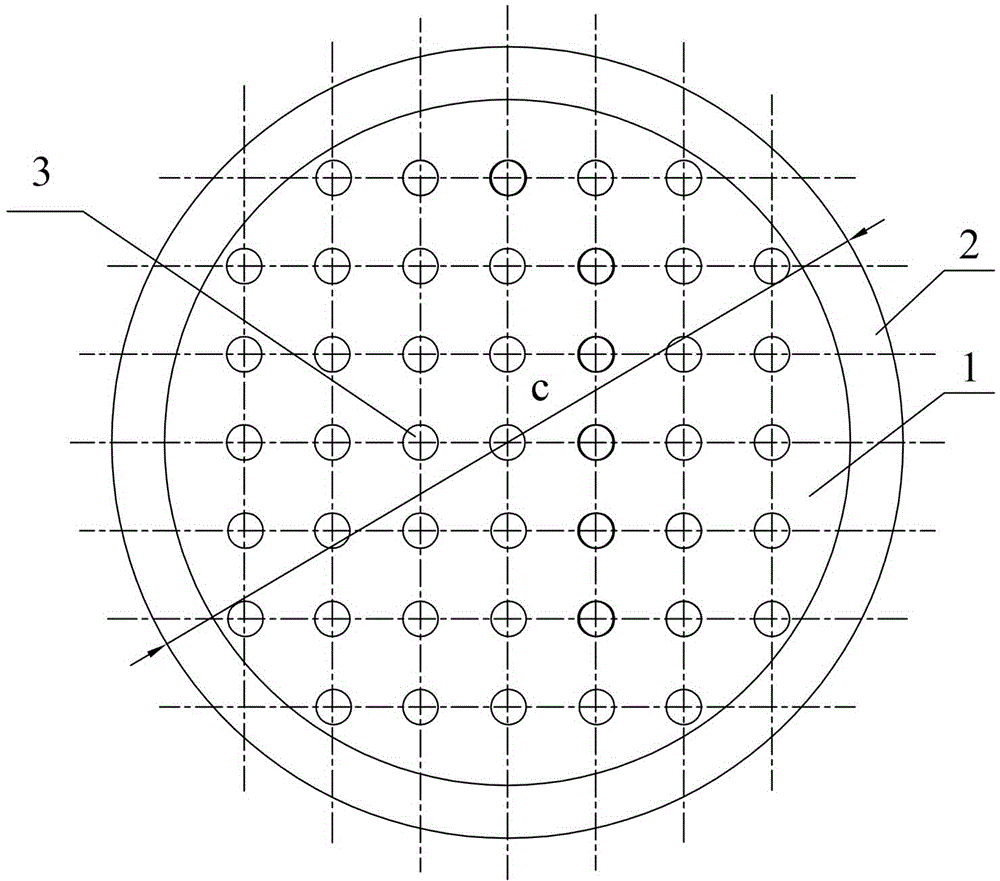

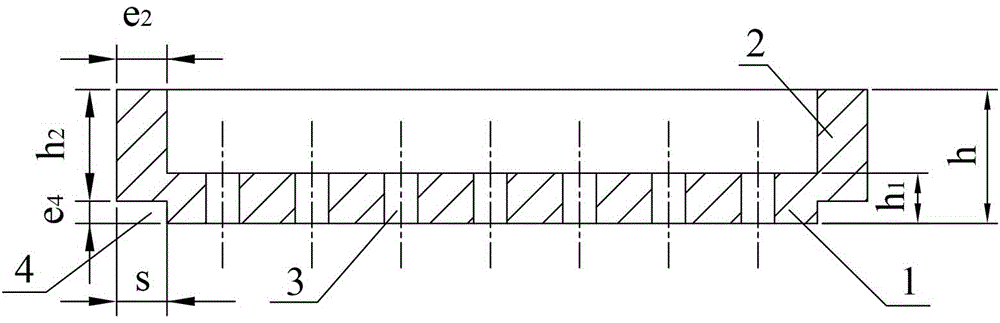

[0026] figure 1 and figure 2 Shown is a kind of graphite boat embodiment that is used for cemented carbide sintering of the present invention, and this graphite boat comprises the disc-shaped graphite boat body that is surrounded by sidewall 2 and bottom plate 1, and this graphite boat body is circular shape, and several through holes 3 are evenly arranged on the bottom plate 1. This structure can not only meet the requirements for gas fluidity in the process of sintering cemented carbide, but also make the atmosphere density distribution inside the graphite boat uniform, so that the sintering The distribution of various components in the formed product is more uniform, and the product quality is more stable.

[0027] The diameter of the through hole 3 is d, 0.2≤d≤6mm, and the preferred value range of the diameter d is 0.5mm≤d≤3mm. The distance n between the central axes of two adjacent through holes 3 is 1.1 to 10 times the diameter d of the through hole, and the preferred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com