Method and device for synchronously analyzing and monitoring band steel by using image identification

A technology of synchronous analysis and image recognition, applied in heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve the problems of only random interval inspection, easy fatigue of strip steel, and inability to use contact sensors to complete strip steel inspection, etc. Achieve the effect of optimizing strip steel operation model, simple use and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

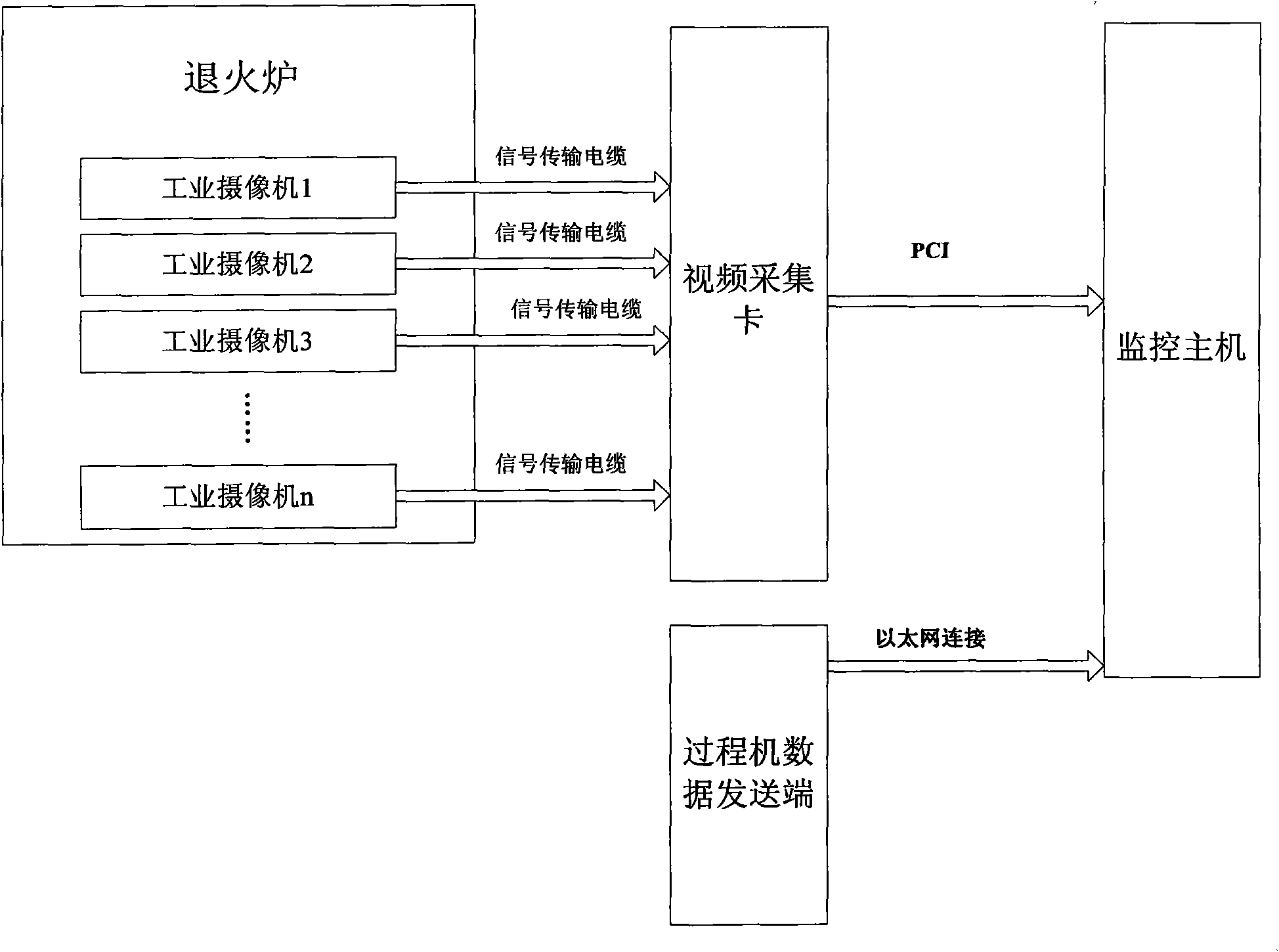

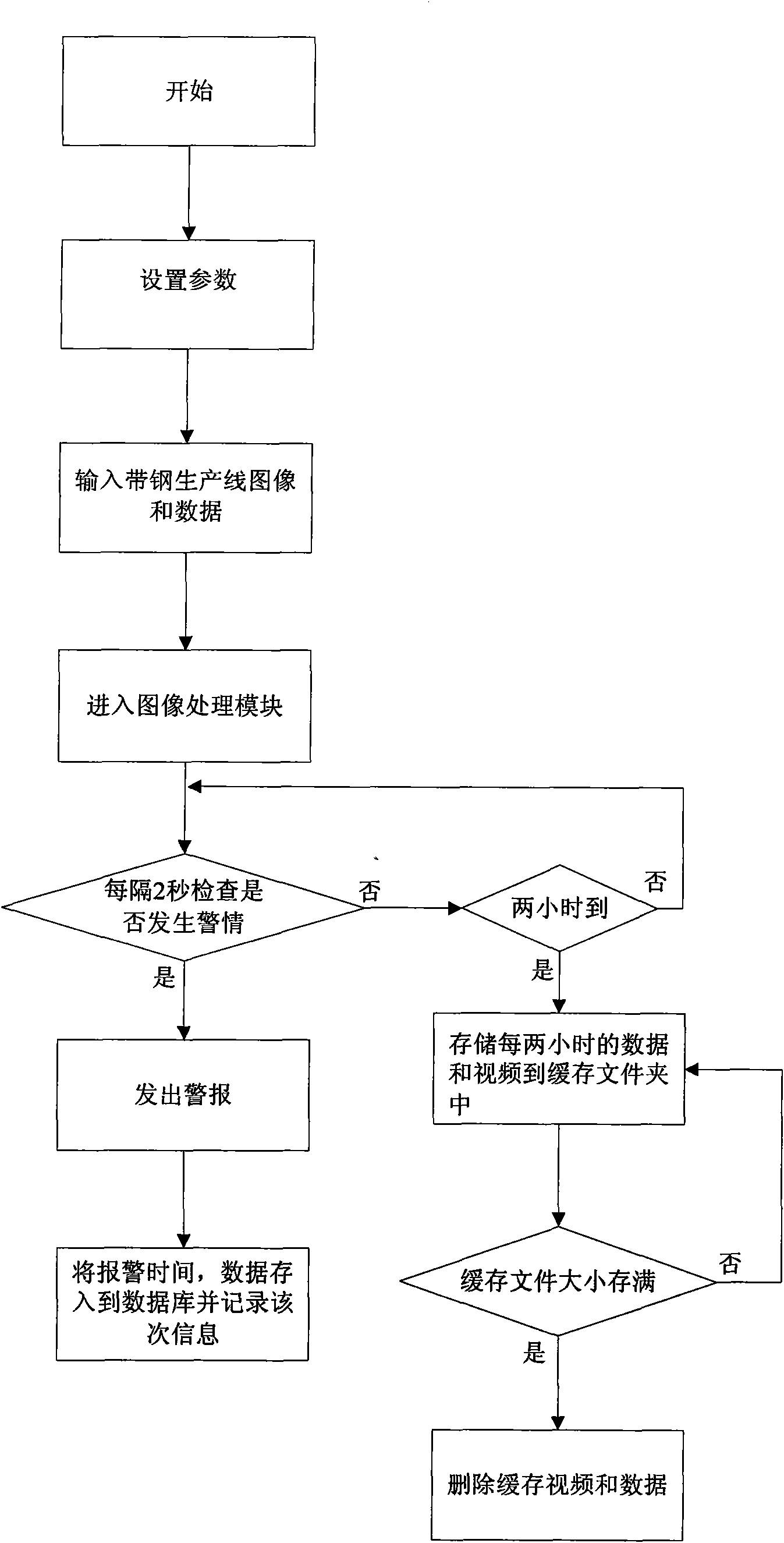

[0059] A strip steel synchronous analysis and monitoring device using image recognition, its composition is as follows figure 1 As shown, including monitoring host, camera, video capture card and process machine. Wherein, the monitoring program installed on the monitoring host includes a video data collection subroutine, a display subroutine, an image processing subroutine, a data management subroutine, an alarm processing subroutine, a playback subroutine, and a video parameter adjustment subroutine.

[0060] The camera is a 9-way industrial camera, and the camera is installed at a vertical angle of the strip steel production line, so that the edge of the strip steel in the monitoring screen can be presented in the most obvious way.

[0061] The video capture card is a video capture card that realizes analog-to-digital conversion and video encoding and decoding functions. The video capture card can be installed on a monitoring computer through a PCI slot, and the camera can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com