Device and process for preparing and producing oils for processing coal tar

A technology of processing process and production device, applied in the field of oil preparation and production device, can solve problems such as environmental pollution, and achieve the effects of good safety, simple design structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

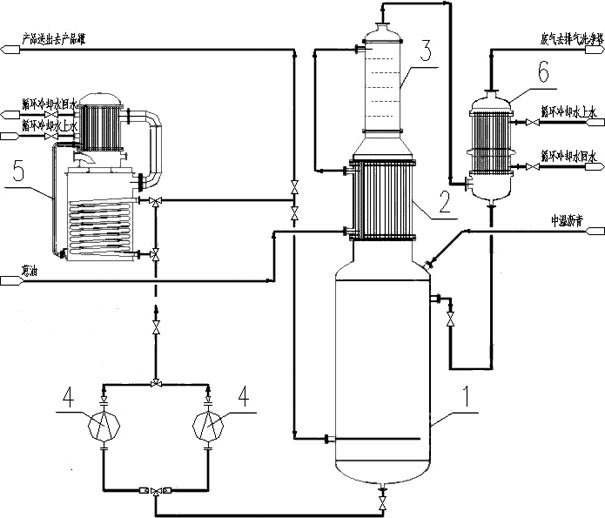

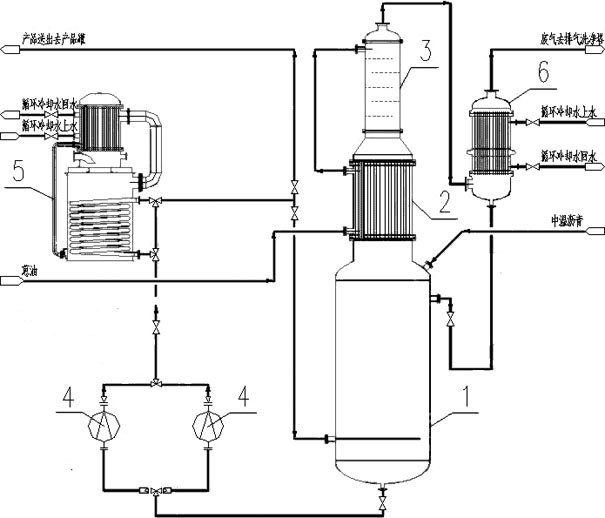

[0065] A schematic diagram of an oil product preparation and production device in a coal tar processing process, such as figure 1 , figure 2 shown.

[0066] The oil preparation and production device of a coal tar processing process of the present invention includes an oil distribution tank 1, an oil gas condenser 2, an oil gas trap 3, an oil distribution delivery pump 4, an oil distribution vaporization condensation cooler 5, and an exhaust gas cooling device 6 and other equipment;

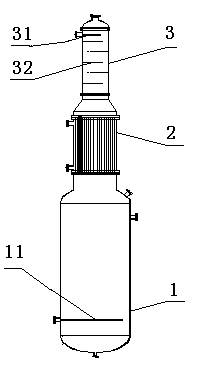

[0067] The oil distribution tank 1, the oil and gas condenser 2, and the oil and gas trap 3 are integrated into one, and from top to bottom are the oil and gas trap 3, the oil and gas condenser 2, and the oil distribution tank 1;

[0068] Such as figure 2 As shown, an anthracene oil distributor 31 is provided at the upper feed port in the oil and gas trap 3, and the anthracene oil distributor adopts a feed distributor used in a chemical tower to ensure that the oil and gas into the oil and g...

Embodiment 2

[0078] As in Example 1, the outlet of the oil distribution vaporization condensing cooler 5 is connected to the oil distribution tank 1 through the return line, and the return line extends into the inside of the oil distribution tank. 11 see figure 2 As shown; the end of the pipe is sealed, and 10 irregular round holes are equidistantly opened under the pipe or side of the return pipe in the horizontal ring, and the hole diameter is 0.32 of the return pipe diameter, that is, r / R=0.32 , other with embodiment 1.

Embodiment 3

[0080] A connected pipeline is provided between the inlet and the outlet of the oil distribution vaporization condensation cooler 5 . The pipeline, the oil distribution delivery pump 4, the oil distribution tank, the return pipe and related pipelines are jointly connected to form an oil circulation circuit, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com