Thin multifunctional solar reflecting coating and preparation method thereof

A multi-functional coating and multi-functional technology, applied in the direction of reflective/signal coatings, coatings, anti-corrosion coatings, etc., can solve the problems of difficult construction, long construction period, and reduced surface flatness, and achieve excellent outdoor durability, Ease of large-area construction and excellent substrate adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Coating formula (mass parts):

[0038] Titanium dioxide: 28

[0039] Talc: 1

[0040] Organic bentonite: 1

[0041] Aluminum tripolyphosphate: 2

[0042] Wetting and dispersing additive: 0.5

[0043] Acrylic resin and curing agent: 25

[0044] Solvent (xylene: ethyl acetate: propylene glycol methyl ether acetate = 4: 4: 1): 15

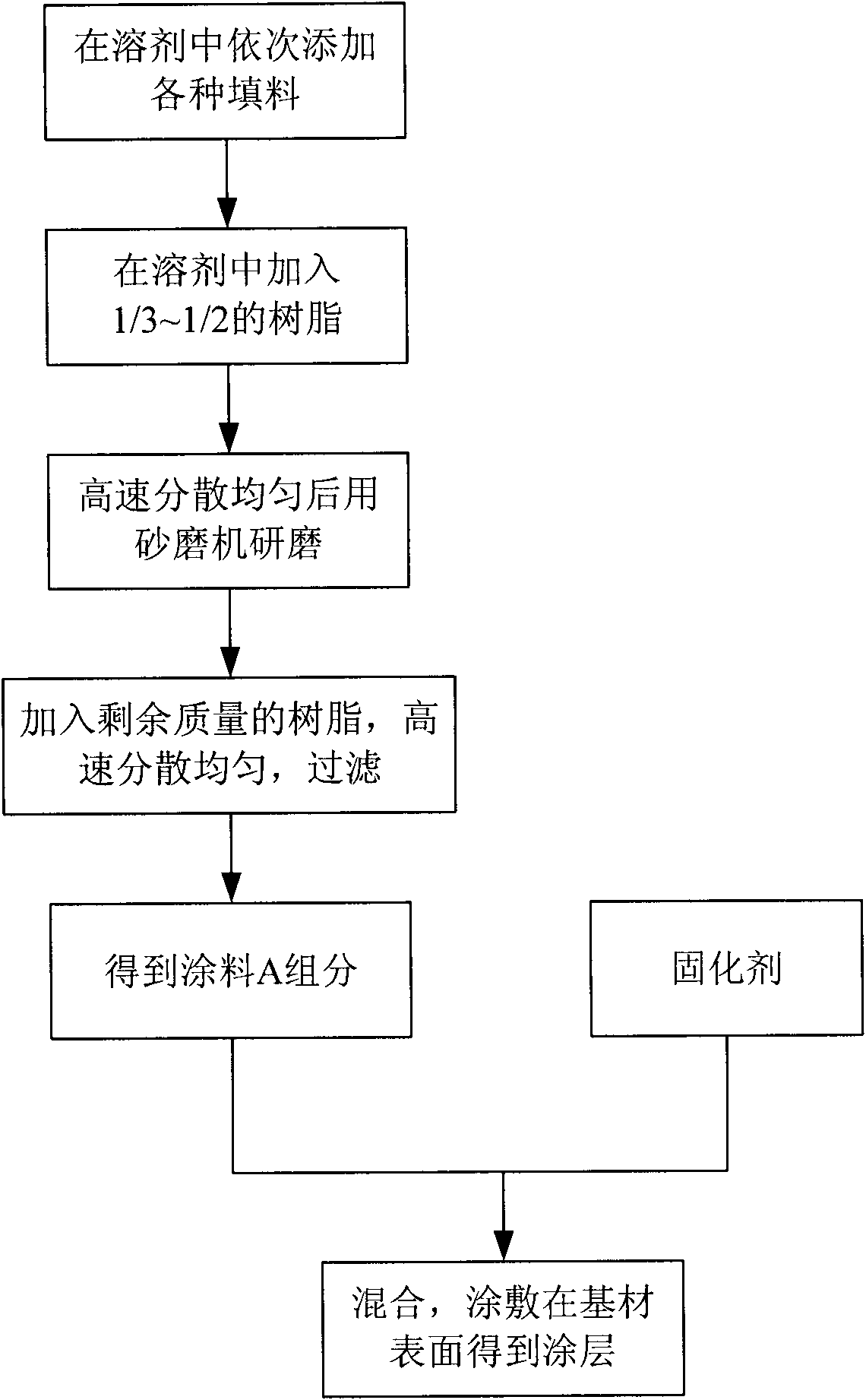

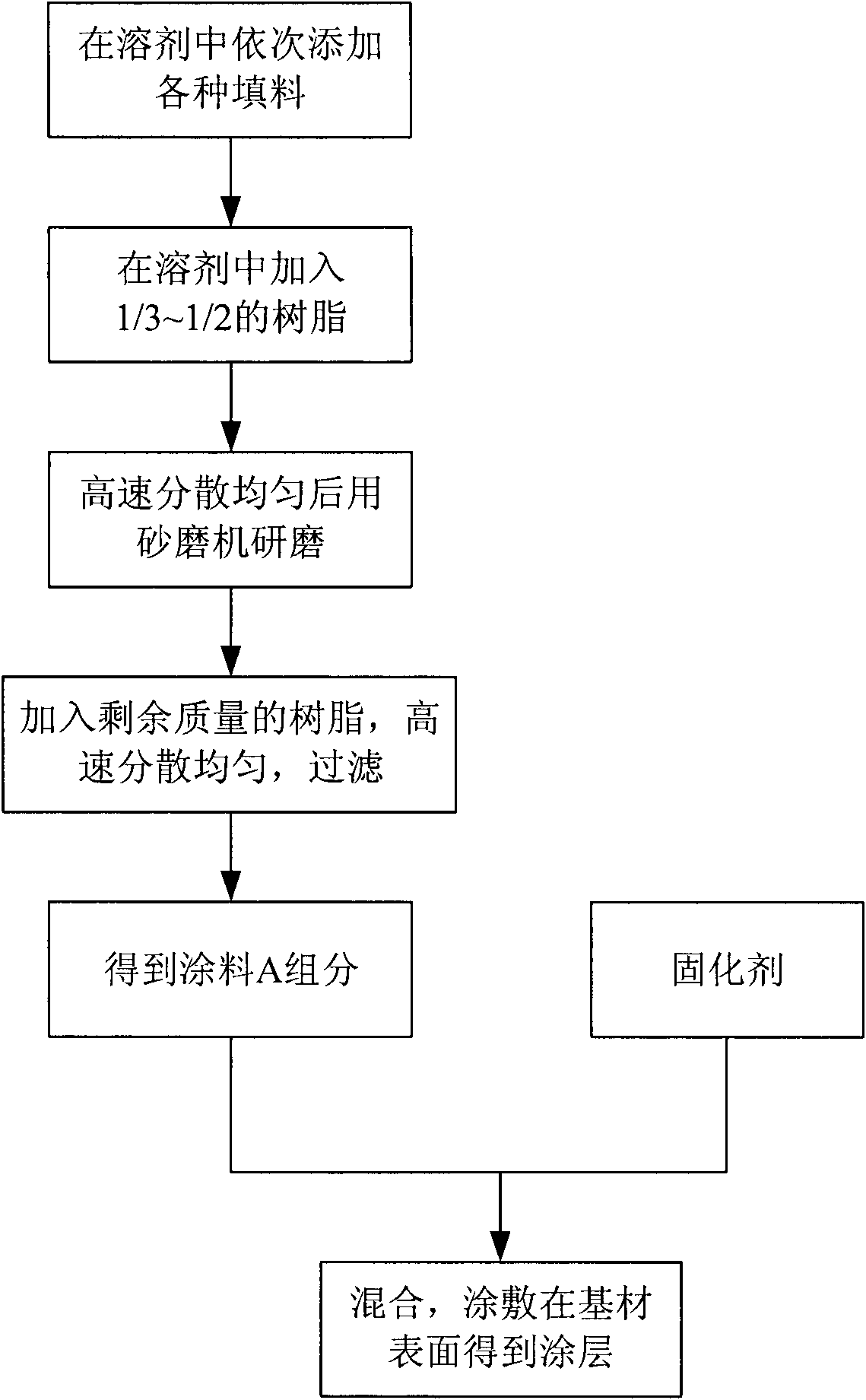

[0045] Coating preparation process such as figure 1 Shown:

[0046] Weigh the mixed solvent according to the proportion, add wetting and dispersing aids, organic bentonite, titanium dioxide, aluminum tripolyphosphate and talcum powder filler and 1 / 2 resin in sequence while dispersing at high speed, and use sand mill after high-speed dispersion Machine grinding for 3 to 4 times until the slurry fineness is ≤40μm; add the remaining 1 / 2 resin in proportion to the ground slurry, and disperse evenly at high speed; then filter the slurry with a 100-mesh fine gauze to obtain the coating Component A: Dispense the coating component A and curing a...

Embodiment 2

[0050] Aluminum oxide: 2

[0051] Titanium dioxide: 28

[0052] Talc: 1

[0053] Organic bentonite: 1

[0055] Wetting and dispersing additive: 0.5

[0056] Acrylic resin and curing agent: 28

[0057] Solvent (butyl acetate: propylene glycol methyl ether acetate = 9: 1): 12

[0058] All the other are with embodiment 1.

Embodiment 3

[0061] Titanium dioxide: 28

[0062] Organic bentonite: 2

[0064] Wetting and dispersing additive: 1.5

[0065] Acrylic resin and curing agent: 30

[0066] Solvent (butyl acetate: propylene glycol methyl ether acetate = 6: 1): 15

[0067] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com