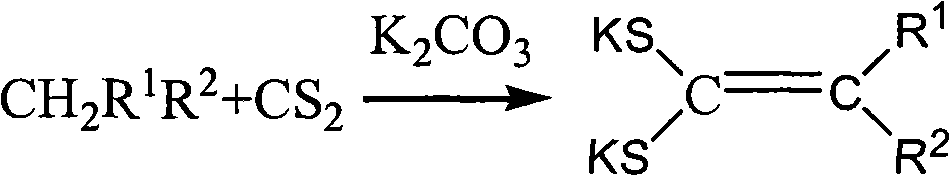

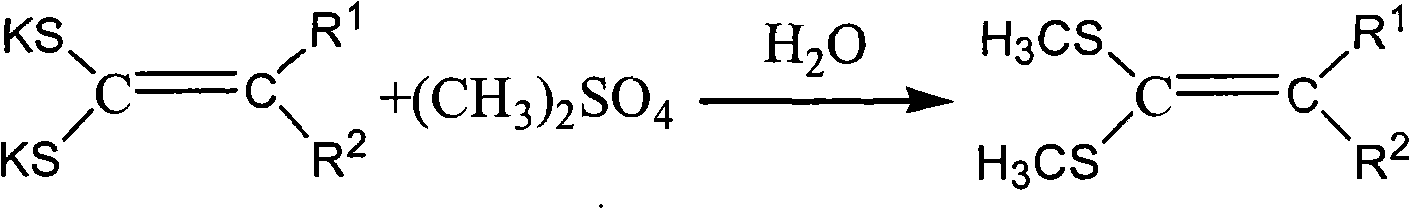

Dimethyl sulphur-based ethylene synthesis method

A technology of dimethylthioethylene and synthetic methods, which is applied in the fields of sulfide preparation, organic chemistry, etc., can solve the problems of serious environmental pollution, many side reactions, violent reactions, etc., and achieve safe and reliable operation, high product yield, good selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, so as to better understand the present invention.

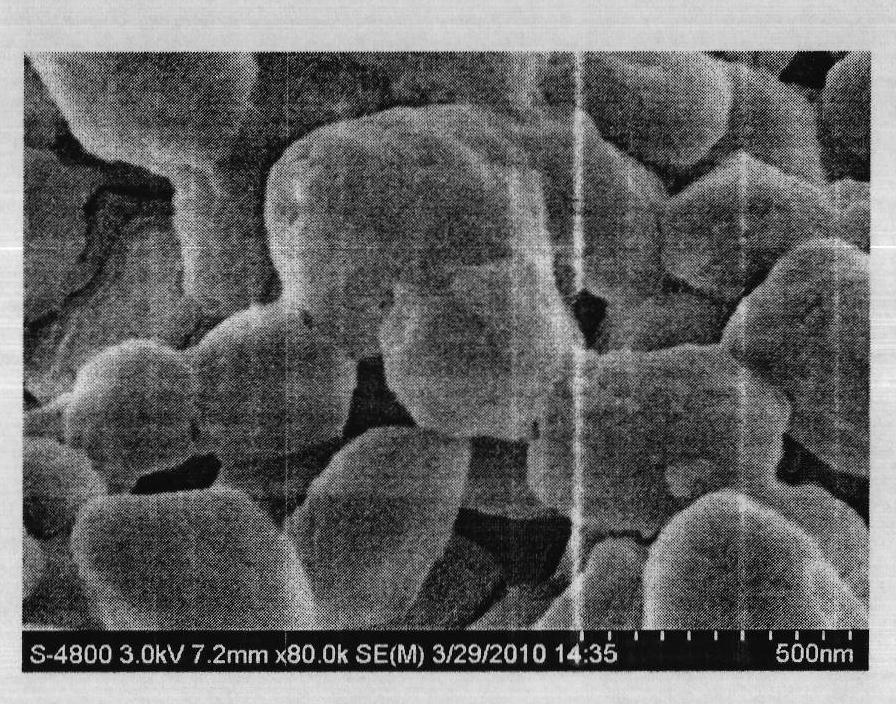

[0020] Preparation of nanopotassium carbonate:

[0021] Anhydrous low-carbon alcohol, such as absolute ethanol or absolute methanol, needs to be used in the nano-potassium carbonate, and its molar ratio to potassium hydroxide is 5~50:1.

[0022] Dissolve 0.3 mole of industrial-grade potassium hydroxide in 300ml of absolute ethanol (or absolute methanol) under stirring, filter to remove insoluble mechanical impurities, add to the reactor, pass carbon dioxide through the gas distributor for reaction, and control the reaction temperature at 30 ℃ or so. Monitor the reaction process by acid-base titration. After the potassium hydroxide in absolute ethanol (or absolute methanol) reacts completely, cool to 20°C and filter. When the liquid is close to the solid liquid level (the solid must not be drained during the filtration process) ), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com