Method for using sulfates as ammonium phosphate anticaking agent

An anti-caking agent and sulfate technology, which is applied in the field of ammonium phosphate and phosphate fertilizer, can solve the problems of caking of ammonium phosphate fertilizers, and achieve the effect of improving slurry viscosity and anti-caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

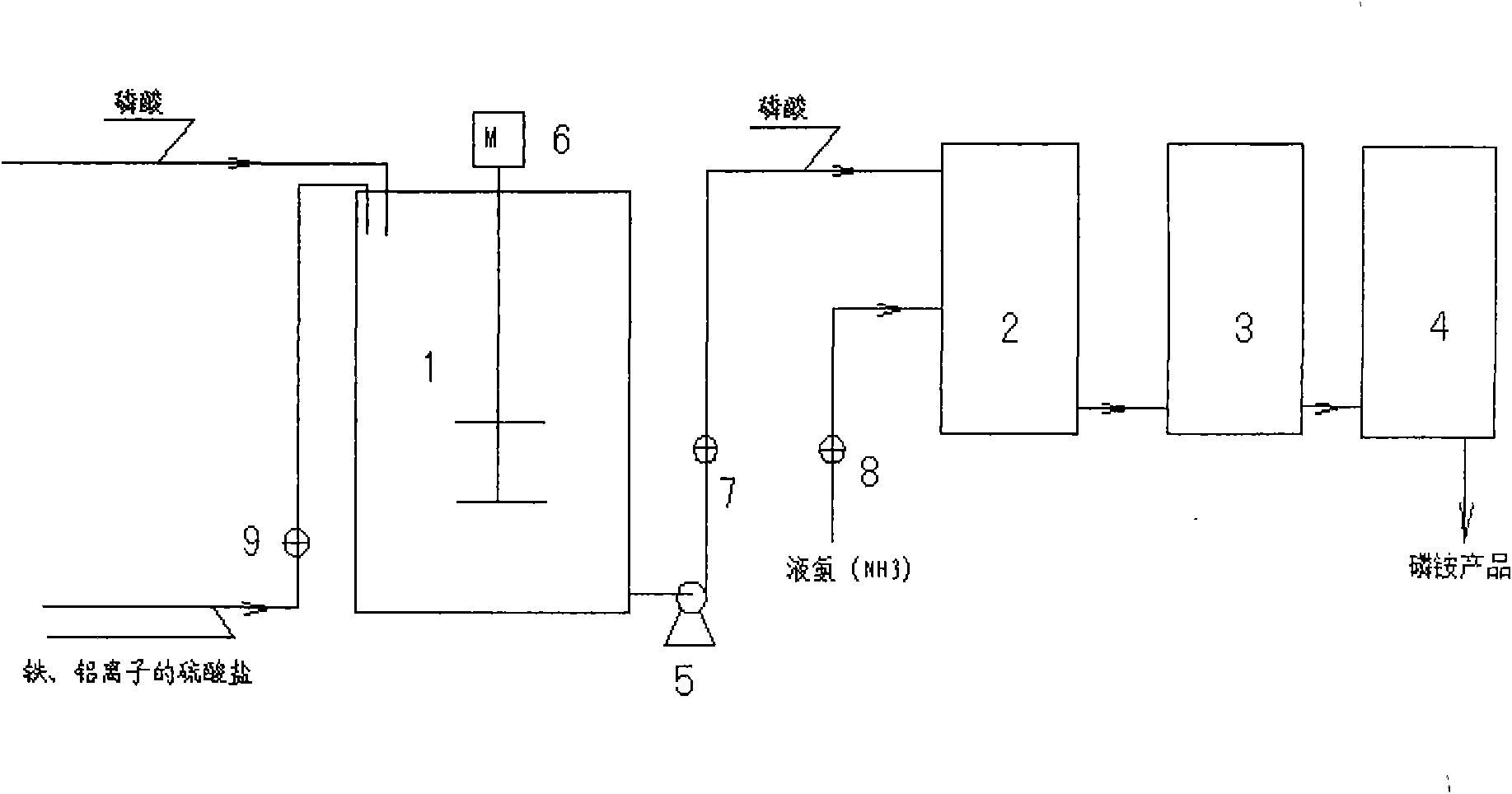

Method used

Image

Examples

Embodiment

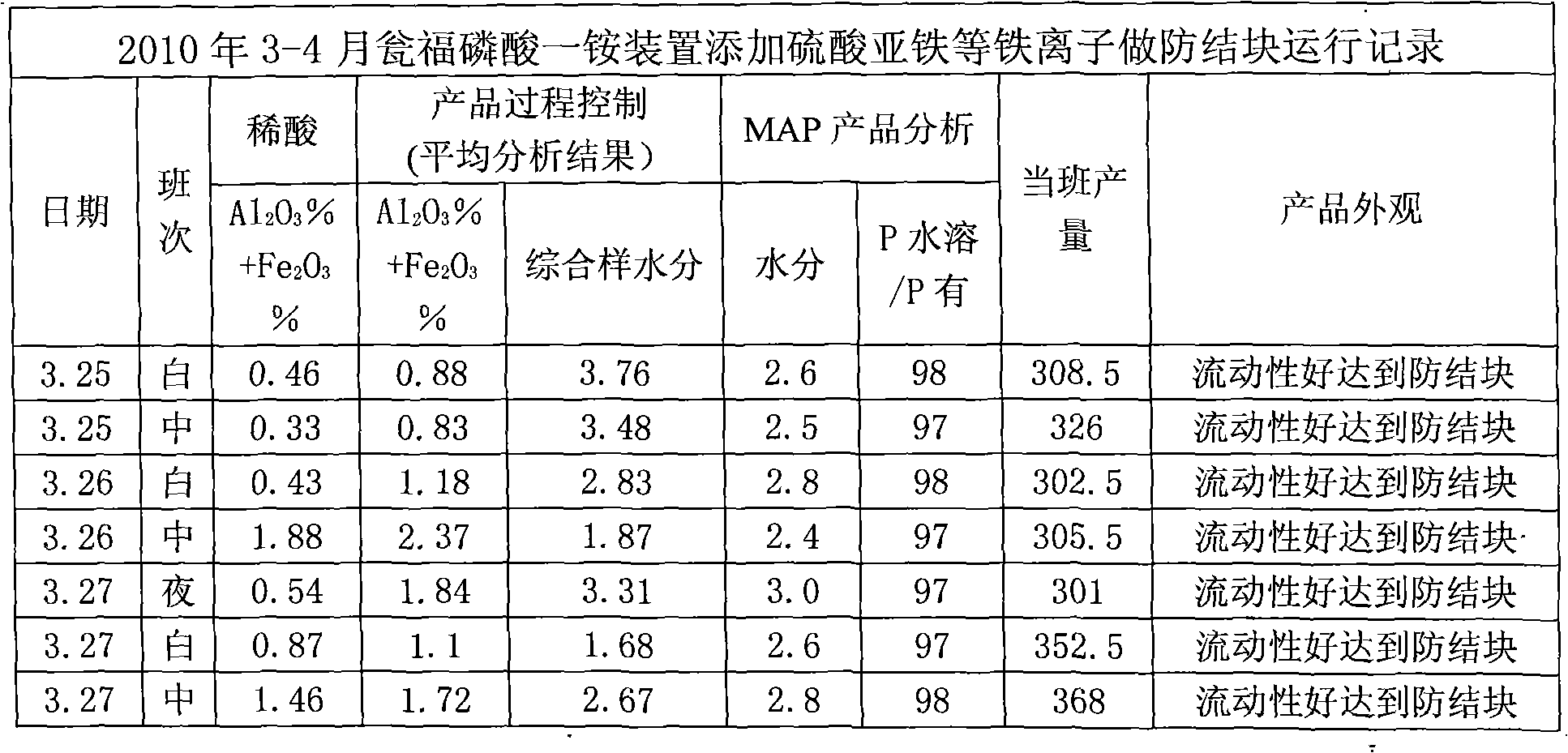

[0013] The invention has been applied in the Wengfu Phosphate Fertilizer Plant of Wengfu (Group) Co., Ltd., and is used in a 400,000-ton / year monoammonium phosphate plant with good effect.

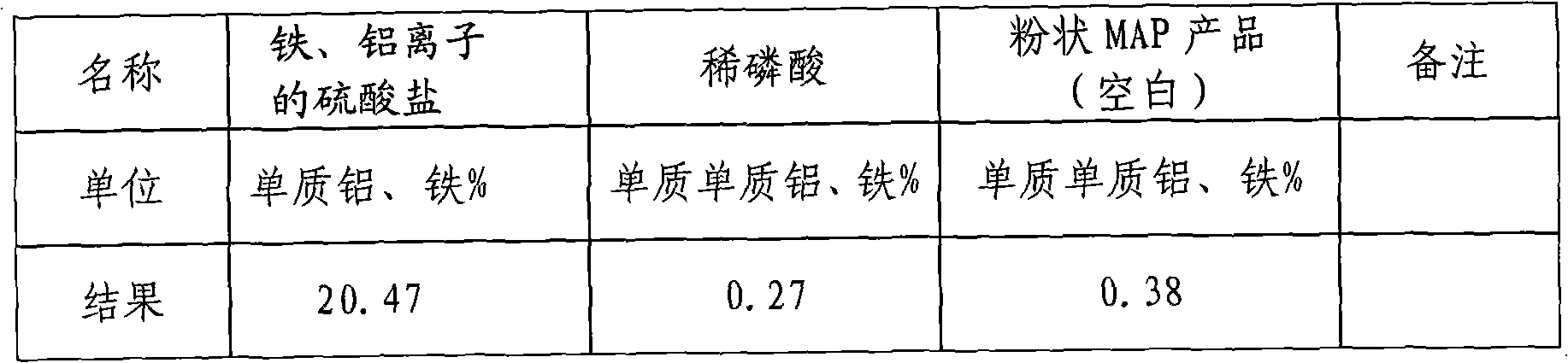

[0014] The data analyzed on February 20, 2010 are as follows:

[0015]

[0016] The specific method is: first add the sulfate of iron and aluminum ions to the raw material for ammonium phosphate production--the dilute phosphoric acid storage tank with a mass fraction of 21% to 30% at a ratio of 0.2% to 3%, and the addition amount is controlled at 2 ~5t / h, the amount of phosphoric acid is 25~50m 3 / h to improve the viscosity of the slurry; stir continuously with a stirrer in the storage tank, mix evenly and transport it to the neutralization reactor with a pump, the reaction between phosphoric acid and ammonia is completed within a few seconds in the reactor, and finally use conventional technology Concentrate and dry the neutralized slurry to produce a qualified monoammonium phosphate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com