Control system integrating elevator control, driving and energy feedback

An energy feedback, elevator control technology, applied in the field of control system, to achieve obvious effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

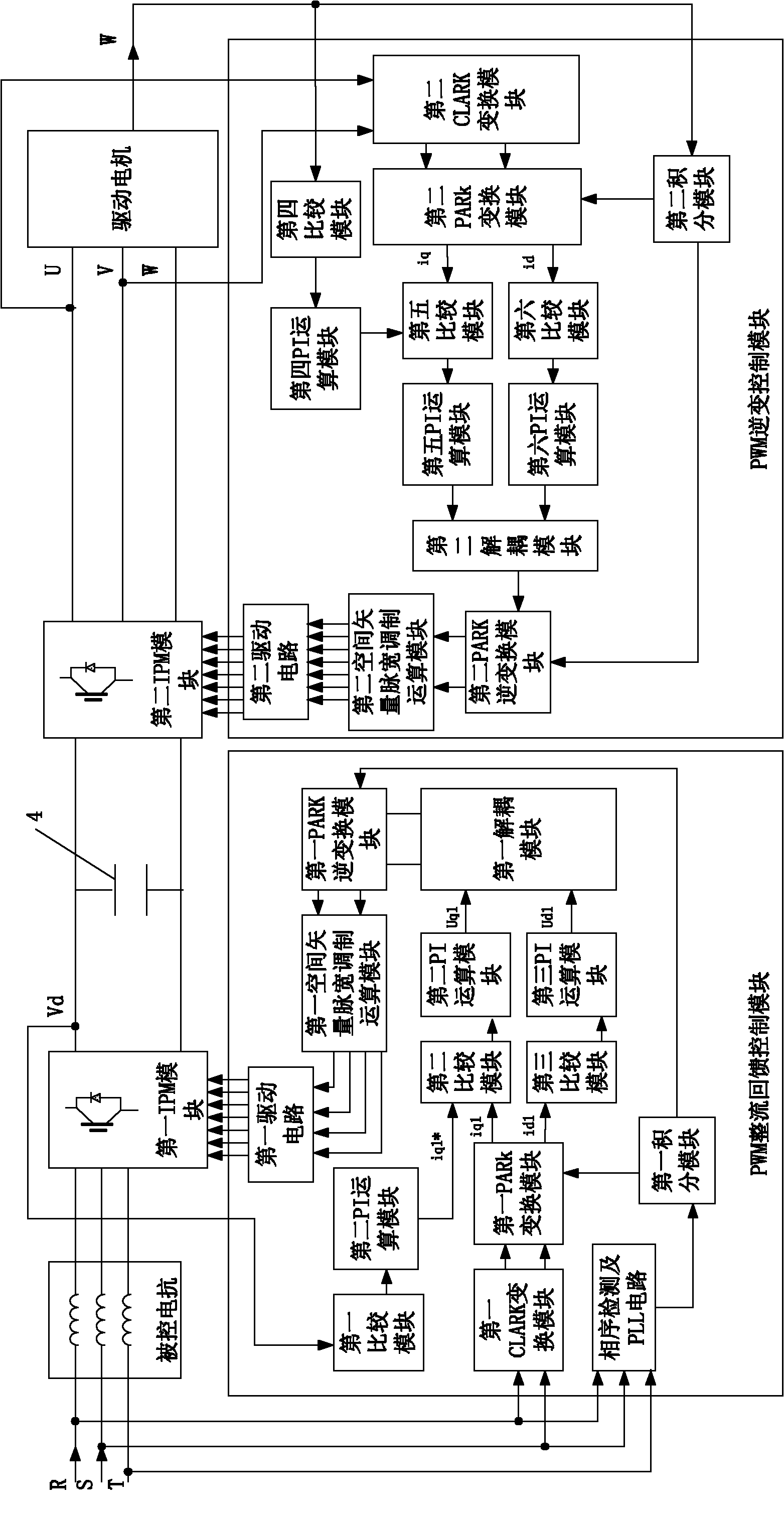

[0022] The present invention adopts dual PWM control technology, and a controlled reactance is set between the three-phase power input terminal and the first IPM module, and the elevator input current, drive motor current, and rotational speed are accurately calculated to achieve precise control of elevator speed, acceleration, and energy The purpose of feeding back to the grid.

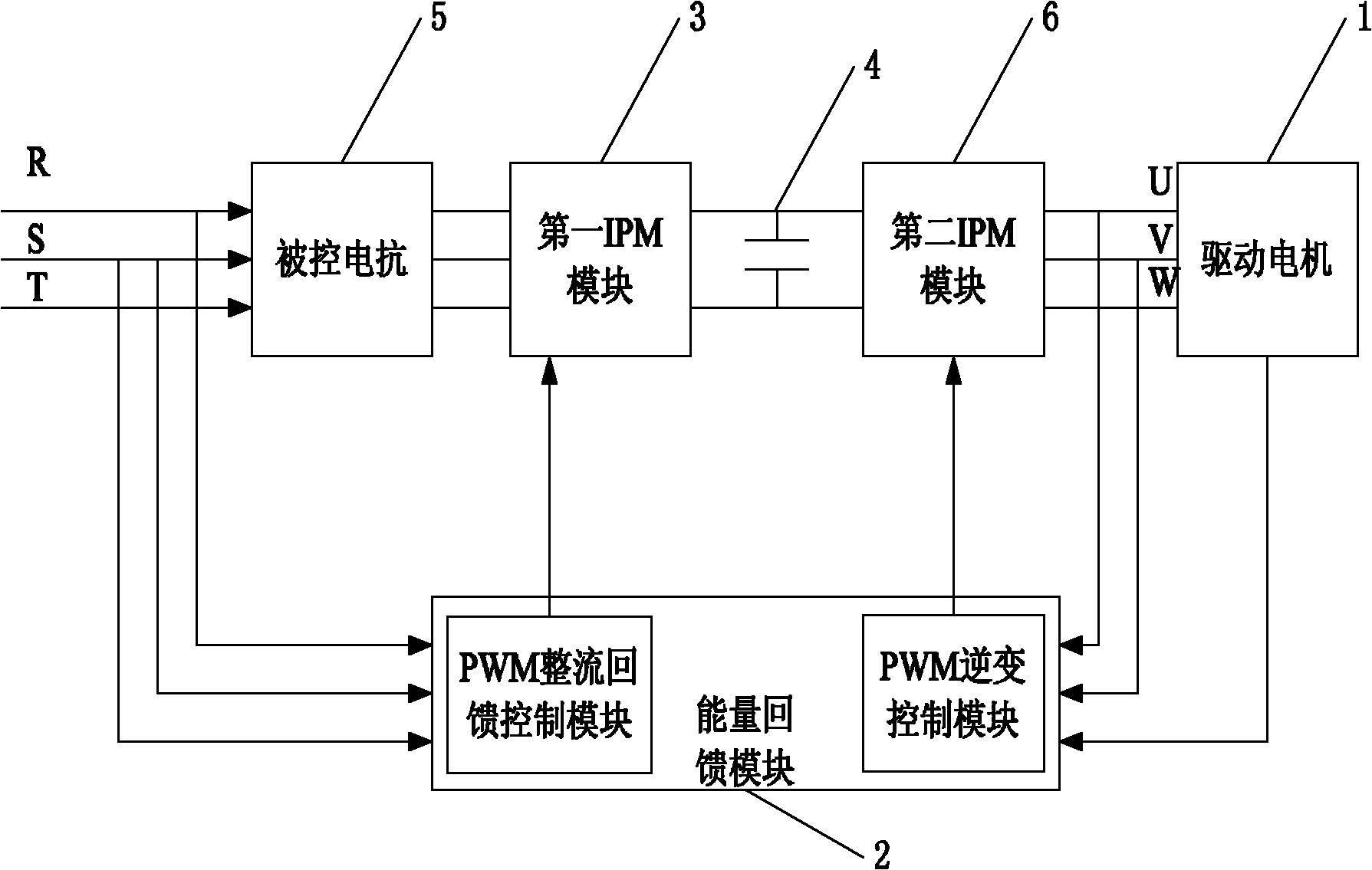

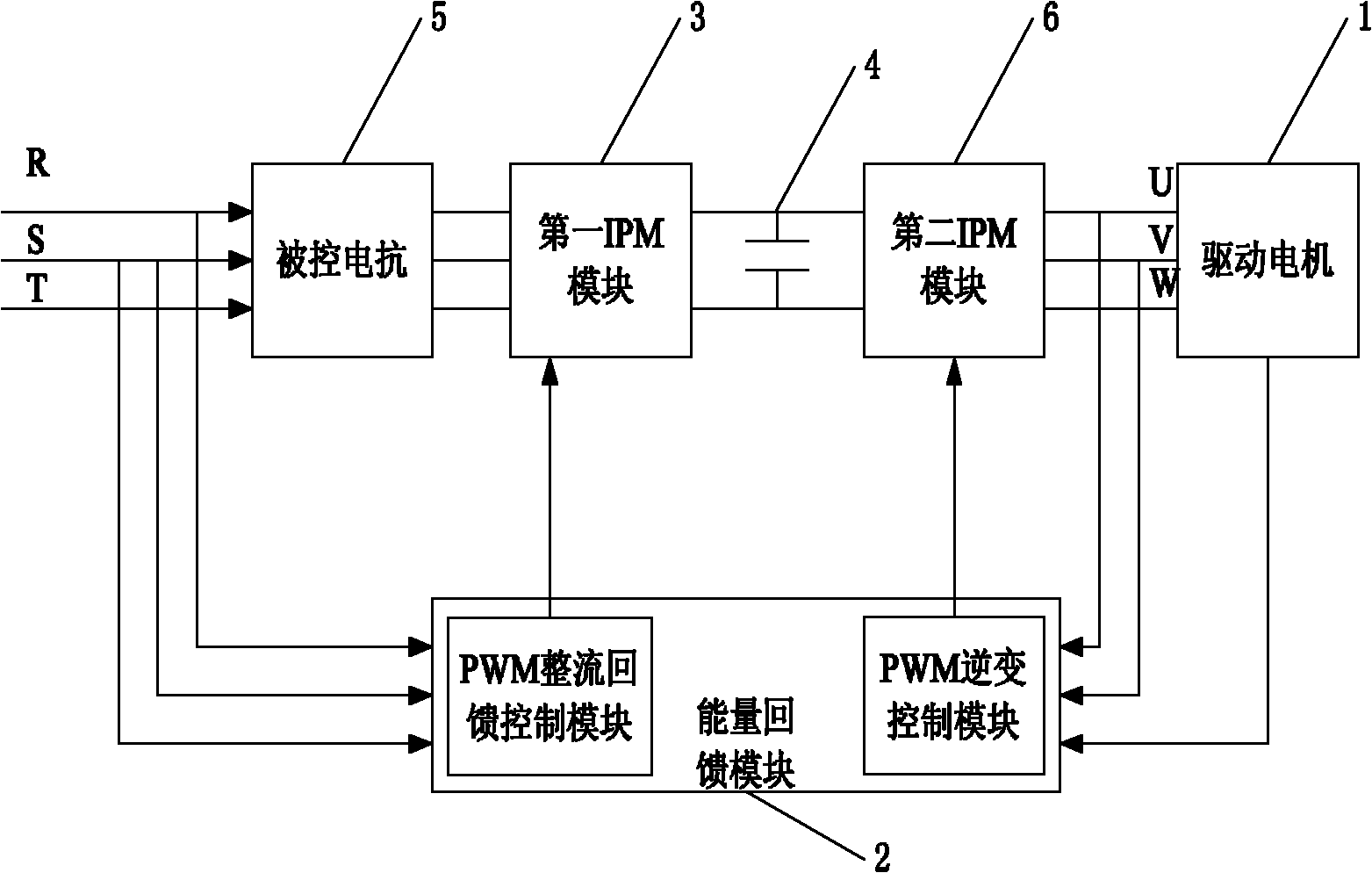

[0023] Such as figure 1 As shown, the present invention includes a driving motor 1 , an energy feedback module 2 , a first IPM module 3 , a second IPM module 6 , a controlled reactance 5 and a filter capacitor 4 . The drive motor 1 is respectively connected to the energy feedback module 2 and the second IPM module 6, the second IPM module 6, the filter capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com