Cutting machine

A cutting machine and release mechanism technology, applied in metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve problems such as damage and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

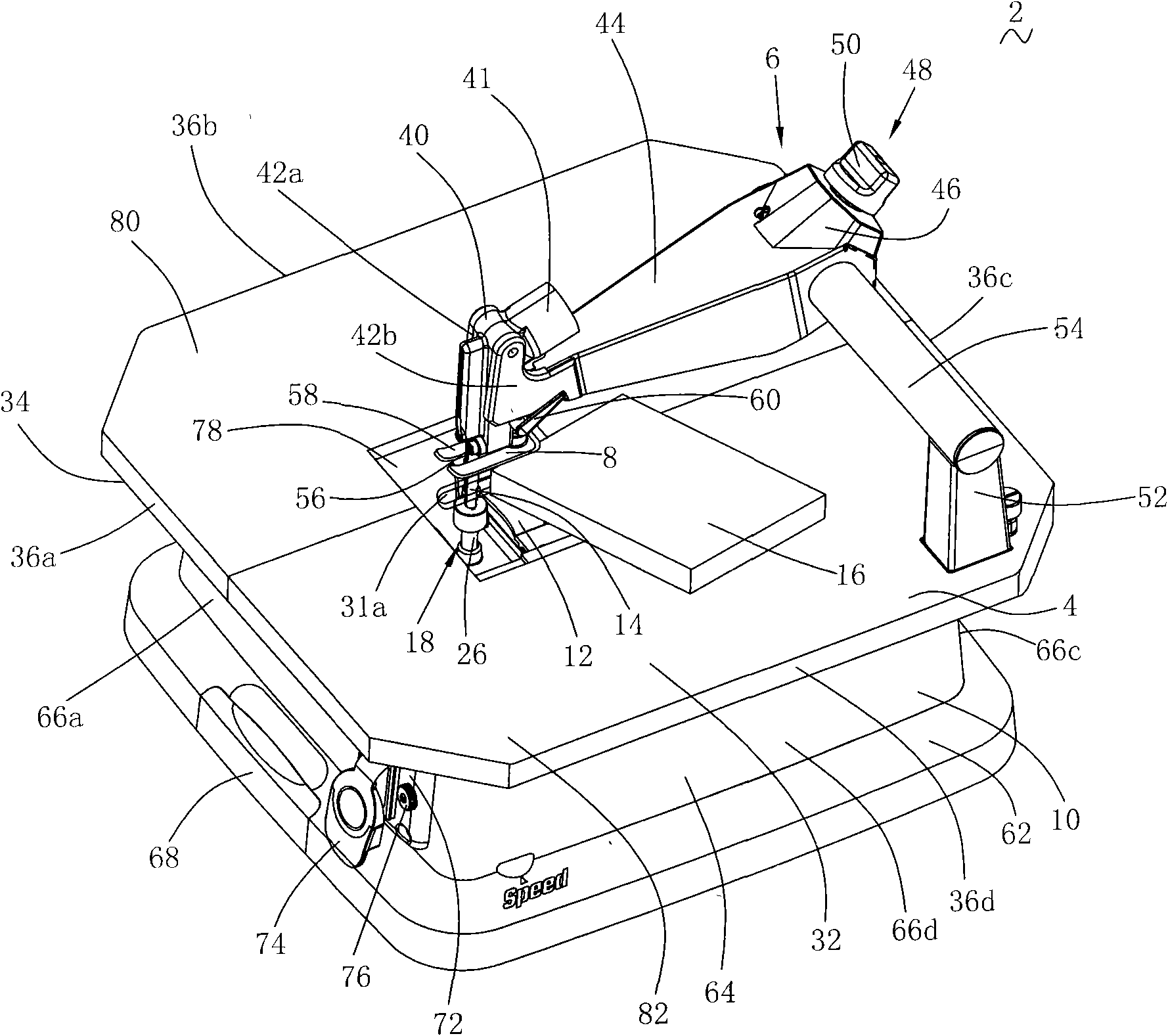

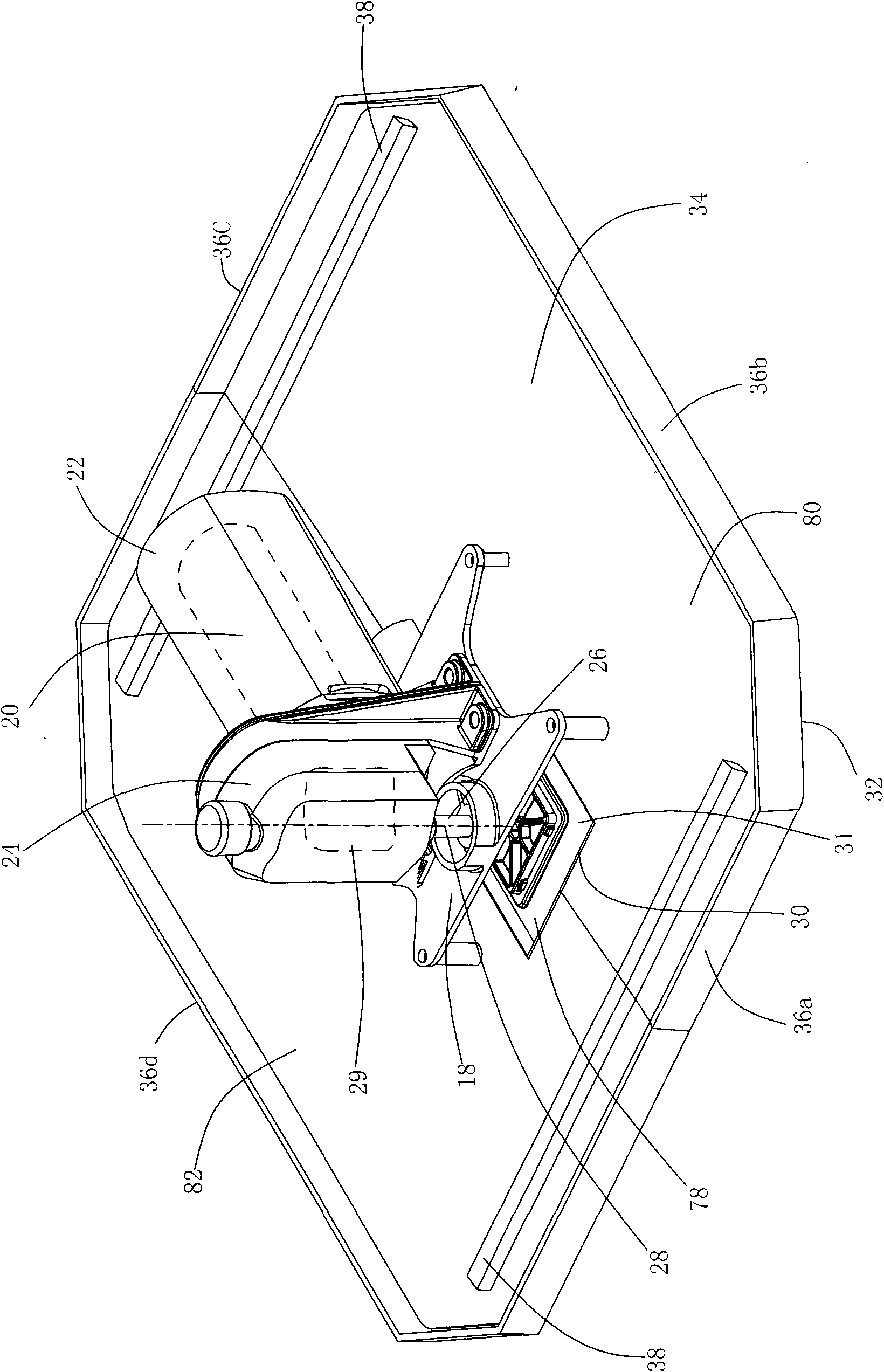

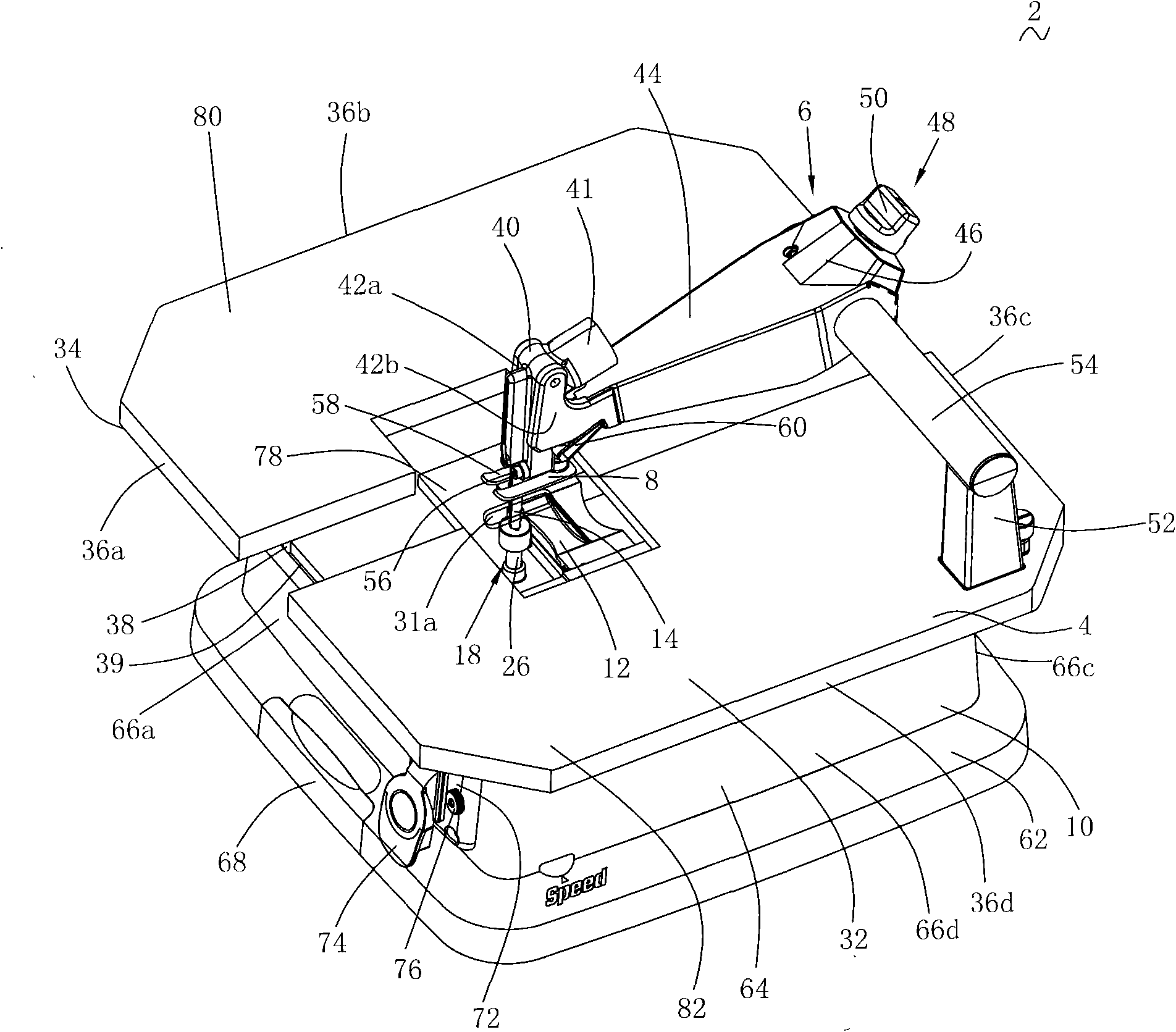

[0038] See attached Figure 1-2 , a cutting machine 2, comprising a workbench 4, a support 10 supporting the workbench 4, a shield assembly 6 arranged on the upper surface 22 of the workbench 4, connected with the shield assembly 6 and adjustable to apply a certain pressure to the workpiece The platen assembly 8 and the cutting mechanism 12 arranged on the lower surface 24 of the workbench 4 .

[0039] According to the operator's usual way of using this type of cutting machine, define figure 1 The middle left is the front part of the cutting machine 2, and the right side is the rear part of the cutting machine 2. The table 4 has an upper surface 32, a lower surface 34, and side walls 36a, 36b, 36c, 36d extending vertically relative to the upper and lower surfaces. The opening 30 is opened on the workbench 4 , located at the front of the cutting machine 2 , and penetrates from the upper surface 32 to the lower surface 34 . The saw blade 14 passes through the opening 30 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com