Full automatic grooving machine

A grooving machine, fully automatic technology, applied in the direction of shearing devices, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of inability to carry out mass production, take up a lot of manpower, and low work efficiency, so as to adapt to large-scale The effects of batch processing and production, high work efficiency, and simple structure and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

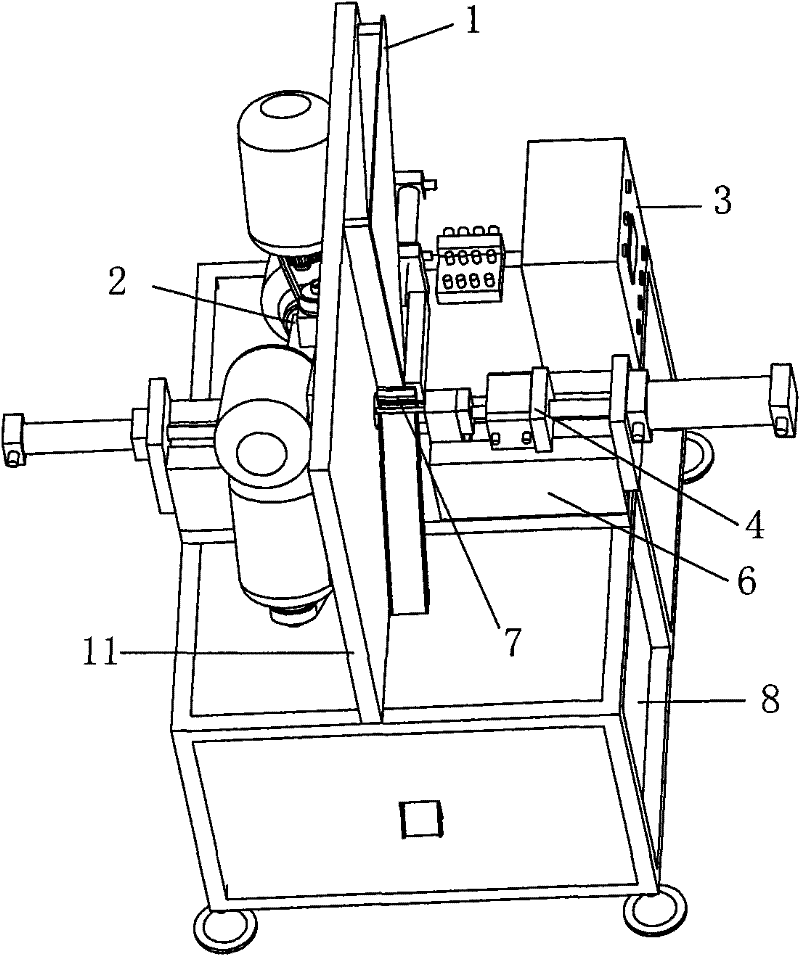

[0015] see Figure 1 to Figure 4 As shown, the fully automatic slotting machine of the present invention comprises a main frame (8), a main board (11) arranged on the main frame (8), and a feeder bracket arranged on one side of the main board (11) (7), and the funnel-type feeding device (1) that is arranged on the feeder bracket (7), and the transmission-type cutting magazine (2) that is arranged on the other side of the main board (11), and is arranged on the funnel-type The workpiece pushing device (4) under the feeding device (1), the feeding bracket (6) arranged under the workpiece pushing device (4), and the main frame (8) for controlling fully automatic grooving A program-controlled electrical device (3) for machine work. It can realize the mechanized and automatic operation of pipe grooving. It has high working efficiency, adapts to mass production, simple structure and composition, reliable operation and low cost. It can well meet multi-directional grooving without d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com