Soak solution for removing toxin in tung meal and method for industrialized detoxification

A technology of soaking liquid and tung meal, which is applied in the field of soaking liquid for removing toxins from tung meal, can solve problems such as unsatisfactory detoxification effect, achieve huge social and economic benefits, and increase protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

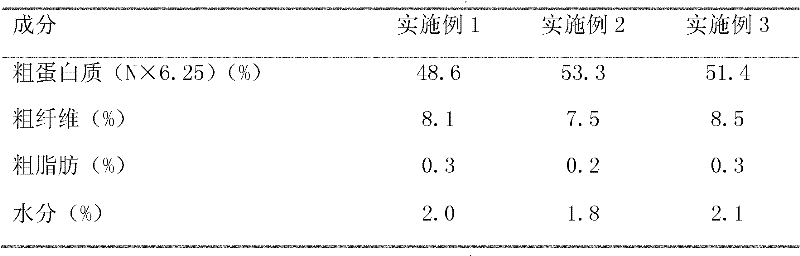

Embodiment 1

[0029] The preparation of embodiment 1 detoxified tung meal

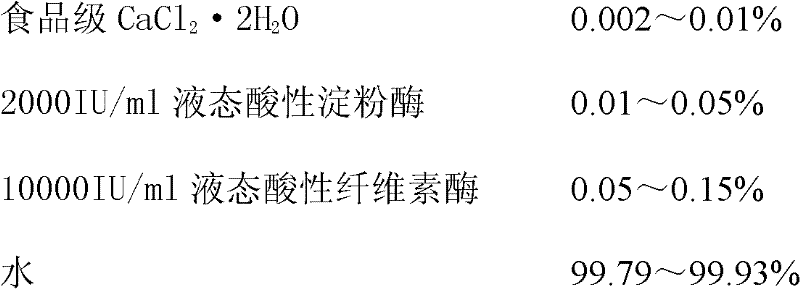

[0030] (1) Preparation of soaking solution: in 3M 3 Add 1 ton of dechlorinated tap water to a reactor with a heating jacket, add 200 grams of 2000 IU / ml liquid acid amylase, food grade CaCl 2. 2H 2 O 20 grams, 10000 IU / ml liquid acid cellulase 1000 grams, adjust the pH value of the solution to 4.5-6.5 with hydrochloric acid;

[0031] (2) tung meal is pulverized and sieved with 80 meshes;

[0032] (3) 1 ton of the above-mentioned tung meal powder is gradually added to the soaking liquid, and constantly stirred when adding, so that the tung meal powder can fully absorb the soaking liquid, and ensure that the liquid level of the soaking liquid is higher than that of the tung meal powder;

[0033] (4) Under continuous stirring, use a heating mantle to increase and maintain the temperature of the reactor at 45-60°C, and then stir once every hour for 48 hours.

[0034] (5) Each 200Kg of n-butanol is added to the react...

Embodiment 2

[0037] The preparation of embodiment 2 detoxified tung meal

[0038] (1) Preparation of soaking solution: Add 1 ton of dechlorinated tap water to a 3M3 reaction kettle with a heating jacket, add 500 grams of 2000IU / ml liquid acid amylase, food grade CaCl 2. 2H 2 O 100 grams, 10000IU / ml liquid acid cellulase 1500 grams, adjust the pH value of the solution to 4.5-6.5 with hydrochloric acid;

[0039] (2) tung meal is pulverized and sieved with 80 meshes;

[0040] (3) 1 ton of the above-mentioned tung meal powder is gradually added to the soaking liquid, and when adding, it is constantly stirred to allow the tung meal powder to fully absorb the soaking liquid, and to ensure that the liquid level of the soaking liquid is higher than that of the tung seed cake powder;

[0041] (4) Under continuous stirring, use a heating mantle to increase and maintain the temperature of the reactor at 45-60°C, and then stir once every hour for 80 hours.

[0042](5) Each 200Kg of n-butanol is add...

Embodiment 3

[0045] The preparation of embodiment 3 detoxified tung meal

[0046] (1) Preparation of soaking solution: in 3M 3 Add 1 ton of dechlorinated tap water to a reactor with a heating jacket, add 100 grams of 2000IU / ml liquid acid amylase, food grade CaCl 2. 2H 2 O 20 grams, 500 grams of 10000IU / ml liquid acid cellulase, adjust the pH value of the solution to 4.5-6.5 with hydrochloric acid;

[0047] (2) tung meal is pulverized and sieved with 80 meshes;

[0048] (3) 1 ton of the above-mentioned tung meal powder is gradually added to the soaking liquid, and when adding, it is constantly stirred to allow the tung meal powder to fully absorb the soaking liquid, and to ensure that the liquid level of the soaking liquid is higher than that of the tung seed cake powder;

[0049] (4) Under continuous stirring, use a heating mantle to increase and maintain the temperature of the reactor at 45-60°C, and then stir once every hour for 120 hours.

[0050] (5) Each 200Kg of n-butanol is add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com