Method and system for regulating power balance of remote adhesive tape conveying machine

A technology of power balance and adjustment method, which is applied in the direction of controlling multiple AC motors, can solve problems such as poor power balance adjustment effect and unstable system operation, and achieves benefits for maintenance and industrial production, stable and reliable operation, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

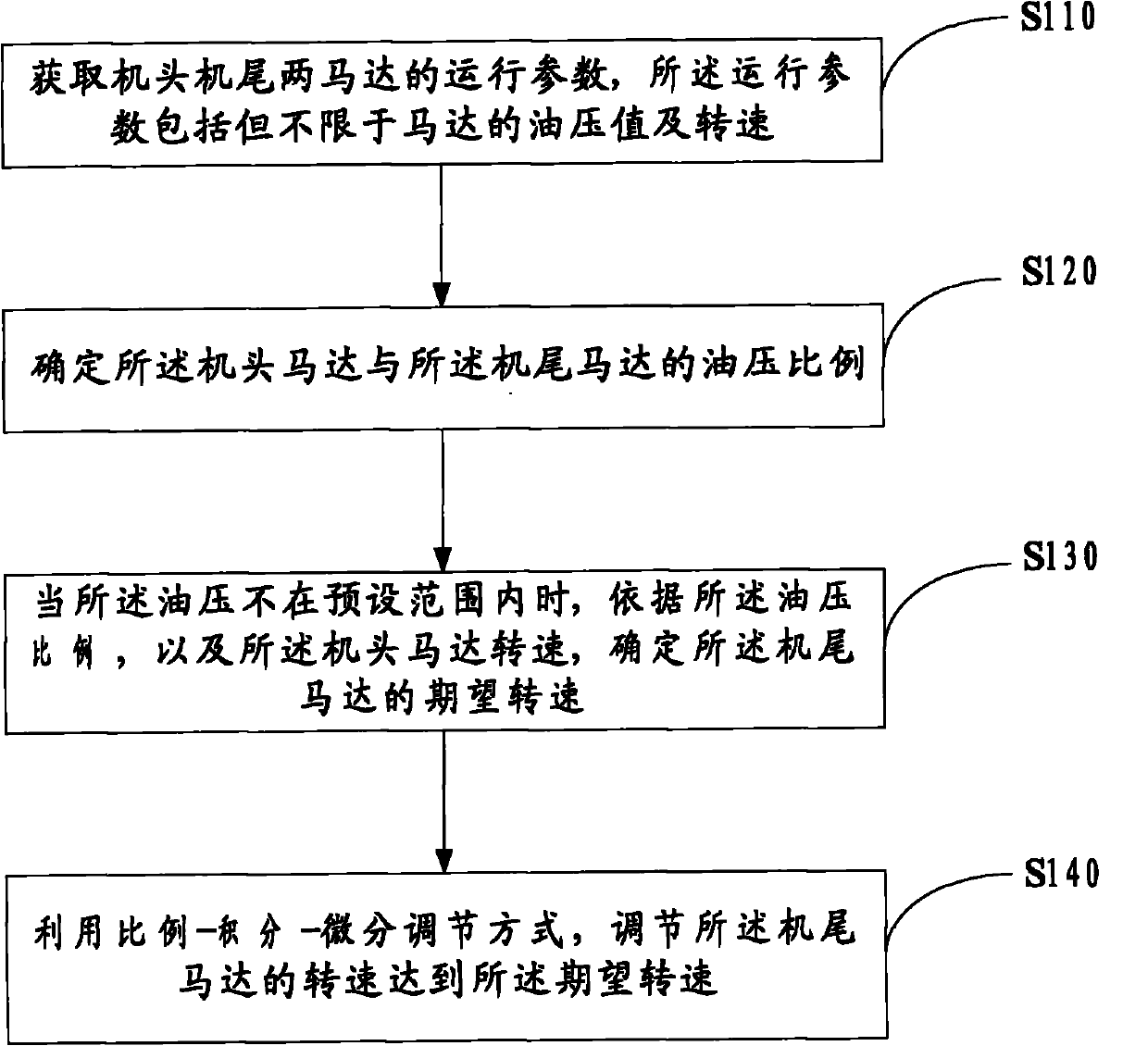

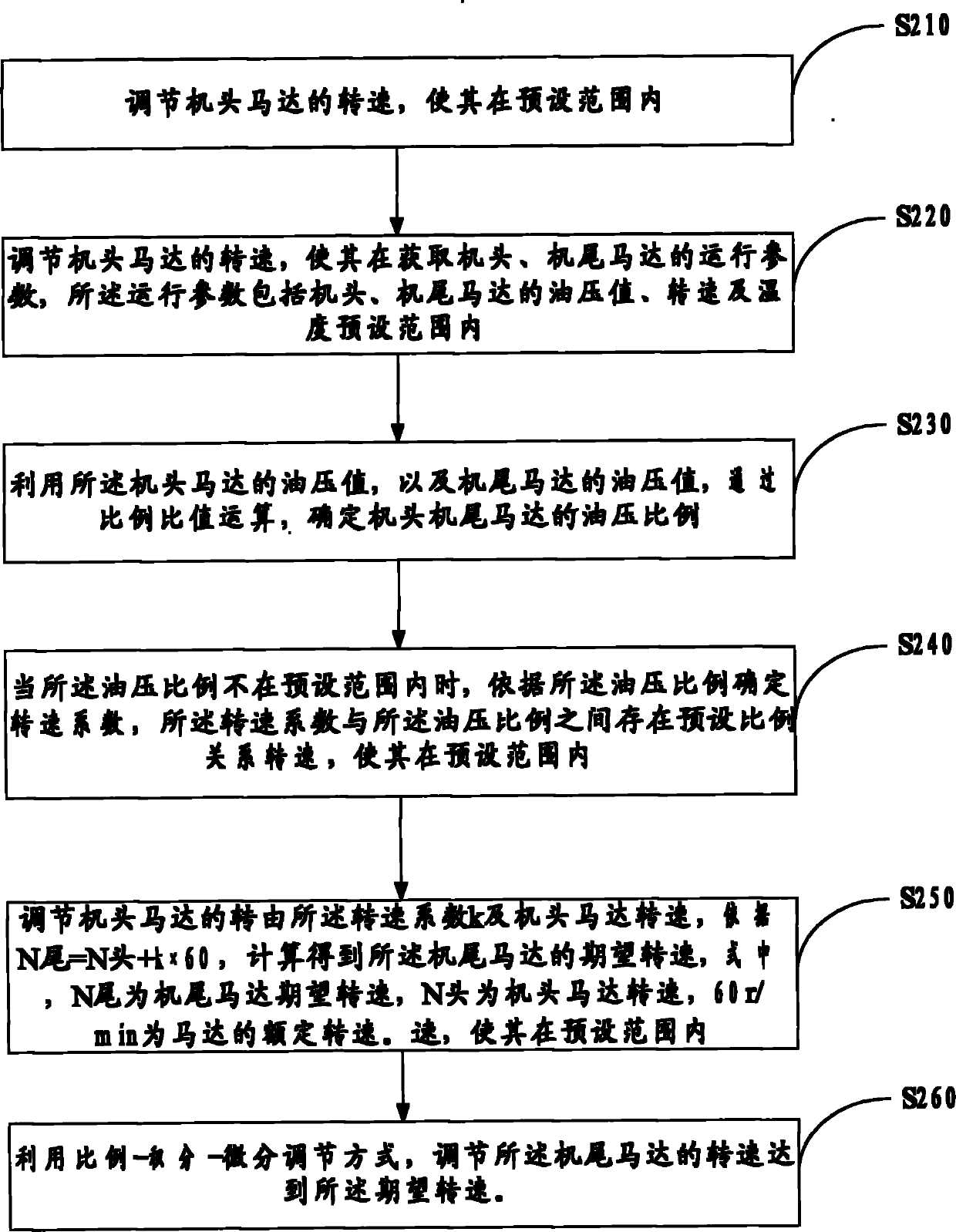

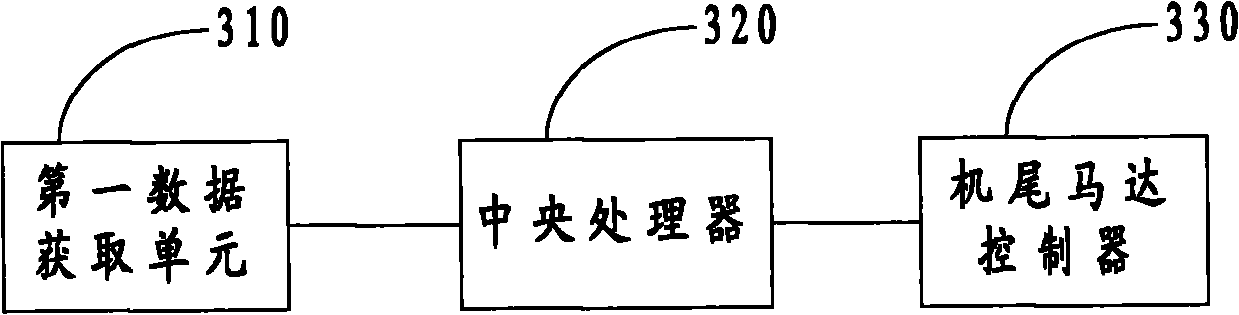

[0043] The embodiment of the present application provides a method for automatically adjusting the power balance of a long-distance conveying tape machine. The long-distance conveying tape machine adopts a hydraulic motor head-to-tail cooperative drive mode, mainly driven by the head motor, referring to the oil pressure ratio of the head and tail motors, Use the controller of the motor itself to adjust the speed of the tail motor so that it is balanced with the output speed of the nose motor. Because there is a certain relationship between the power of the motor and its output speed, the output speed of the head and tail motors is balanced. Therefore, the power of the nose and tail reaches Balanced state, thereby improving the stability and reliability of the system operation.

[0044] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com