Directional output disc micro-cavity laser device

A laser and microcavity technology, applied in the structure of optical resonator cavity, structure of optical waveguide semiconductor, etc., to achieve the effects of good model selection characteristics, high-efficiency directional optical power output, and high coupling output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

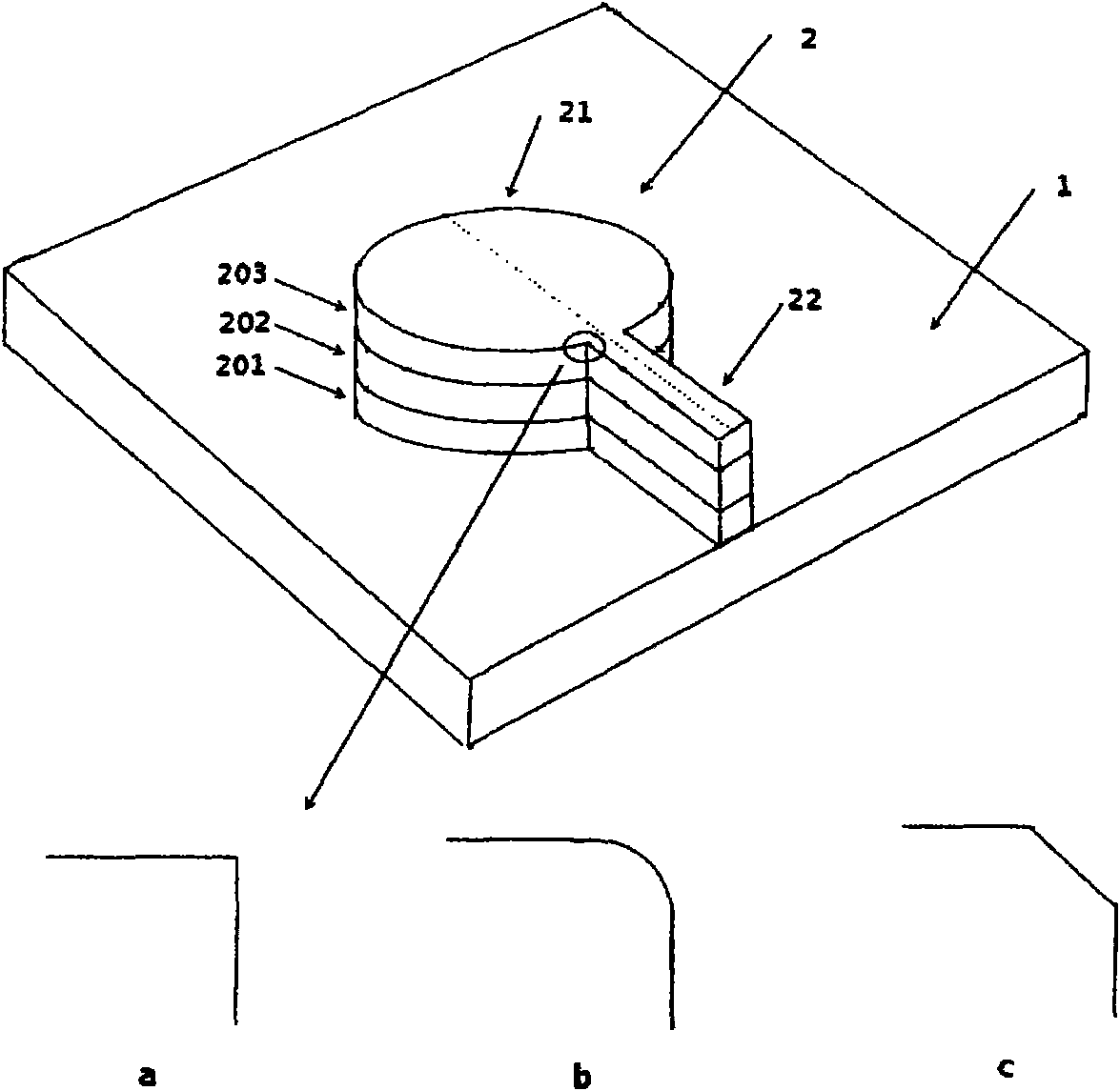

[0026] Combine below Figure 1-Figure 4 Introduce the present invention in detail:

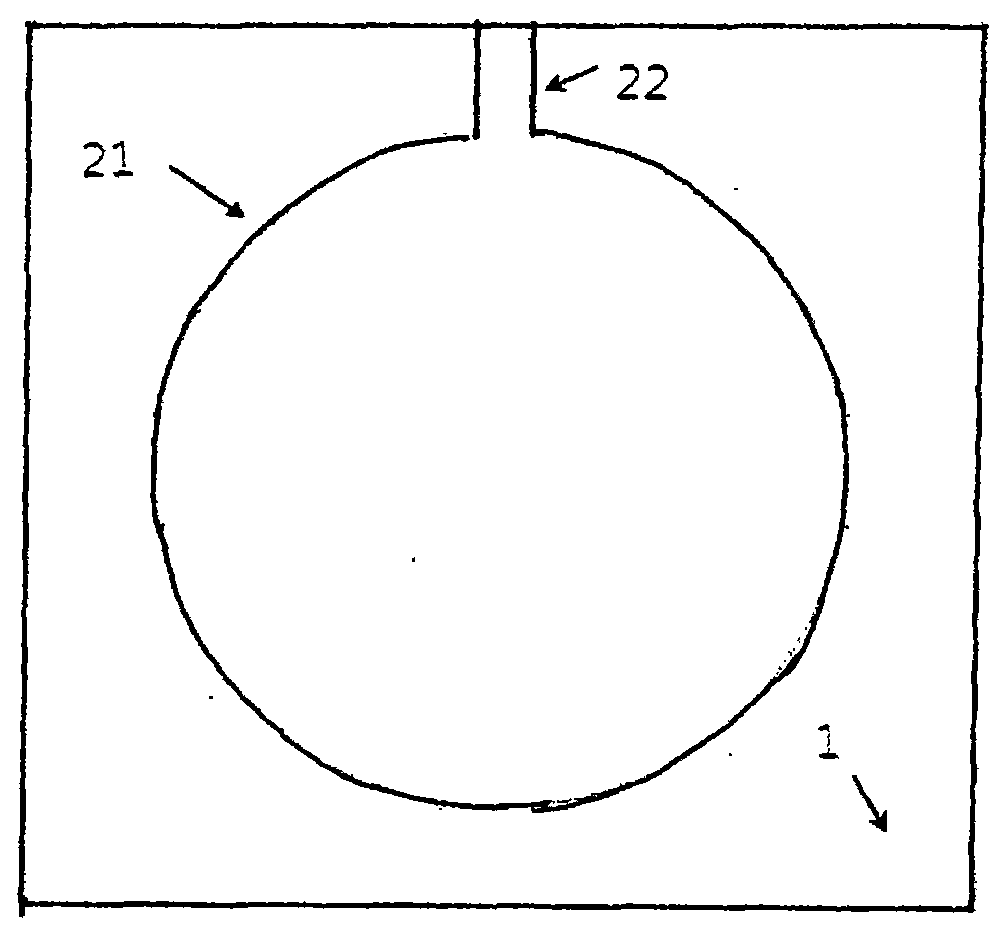

[0027] see figure 1 , figure 2 As shown, the present invention is a disk microcavity laser with an output waveguide, which includes:

[0028] A substrate 1, the shape of the substrate 1 is a rectangle, one side above it is a resonant cavity 21, and the other side is a strip-shaped output waveguide 22 ( figure 1 );

[0029] The resonant cavity 21 is fabricated on the substrate 1;

[0030] The strip-shaped output waveguide 22 is fabricated on the substrate 1 and connected to the side of the resonant cavity 21;

[0031] Wherein the resonant cavity 21 is a cylindrical structure in the direction perpendicular to the substrate 1, and its cross section is rectangular. The resonant cavity 21 includes: a lower confinement layer 201, which is connected to the substrate 1; an active layer 202, the active region 202 is made on the lower confinement layer 201, and its shape is the same as that of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com