Cold and heat metering isenthalpic difference calibration weighting method for central air-conditioning fan coil

A technology for fan coil unit and heat measurement, which is applied in the heat metering and billing, and the cooling field of central air-conditioning fan coil unit system, which can solve the problems of increasing the difficulty of calibration, linking temperature and energy consumption, and the calibration method is not simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

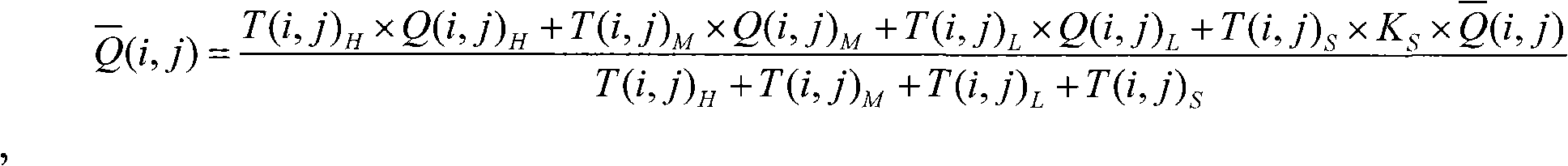

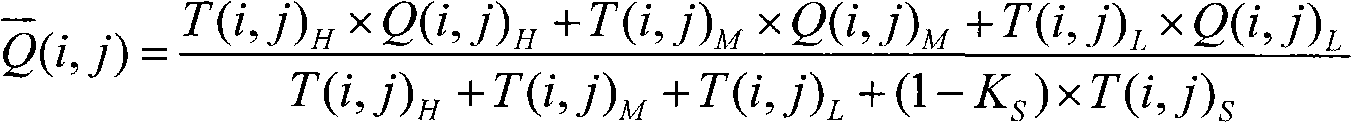

[0044] A central air-conditioning fan-coil cooling and heat metering isothalpy difference calibration weighting method of the present invention comprises the following steps:

[0045] One. The technical scheme adopted in the present invention

[0046] 1) On-site calibration of the weighted value of the fan coil unit under various wind speeds, the calibration process is as follows:

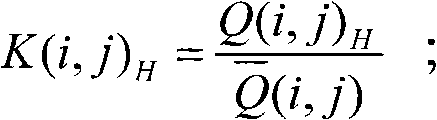

[0047] 1.1) By checking the product manual of the fan coil unit, input the total heat corresponding to the high, medium and low wind speed into the metering thermostat. These three values are respectively Q(i, j) H , Q(i,j) M , Q(i,j) L . Among them, i represents the number of layers; j represents the serial number of the coil;

[0048] 1.2) Put the weighted value K(i, j) of the fan coil unit shutdown status into the metering thermostat S . K(i, j) S Need to measure offline. Determination method: K(i, j) S =K S =Indoor and outdoor enthalpy difference of air-conditioned room / indoor and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com