Pneumatic oblique stop valve with lock for corrugated tube

A bellows and stop valve technology, applied in the field of lock stop valves, to achieve good anti-corrosion and anti-friction performance, good anti-friction performance, and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

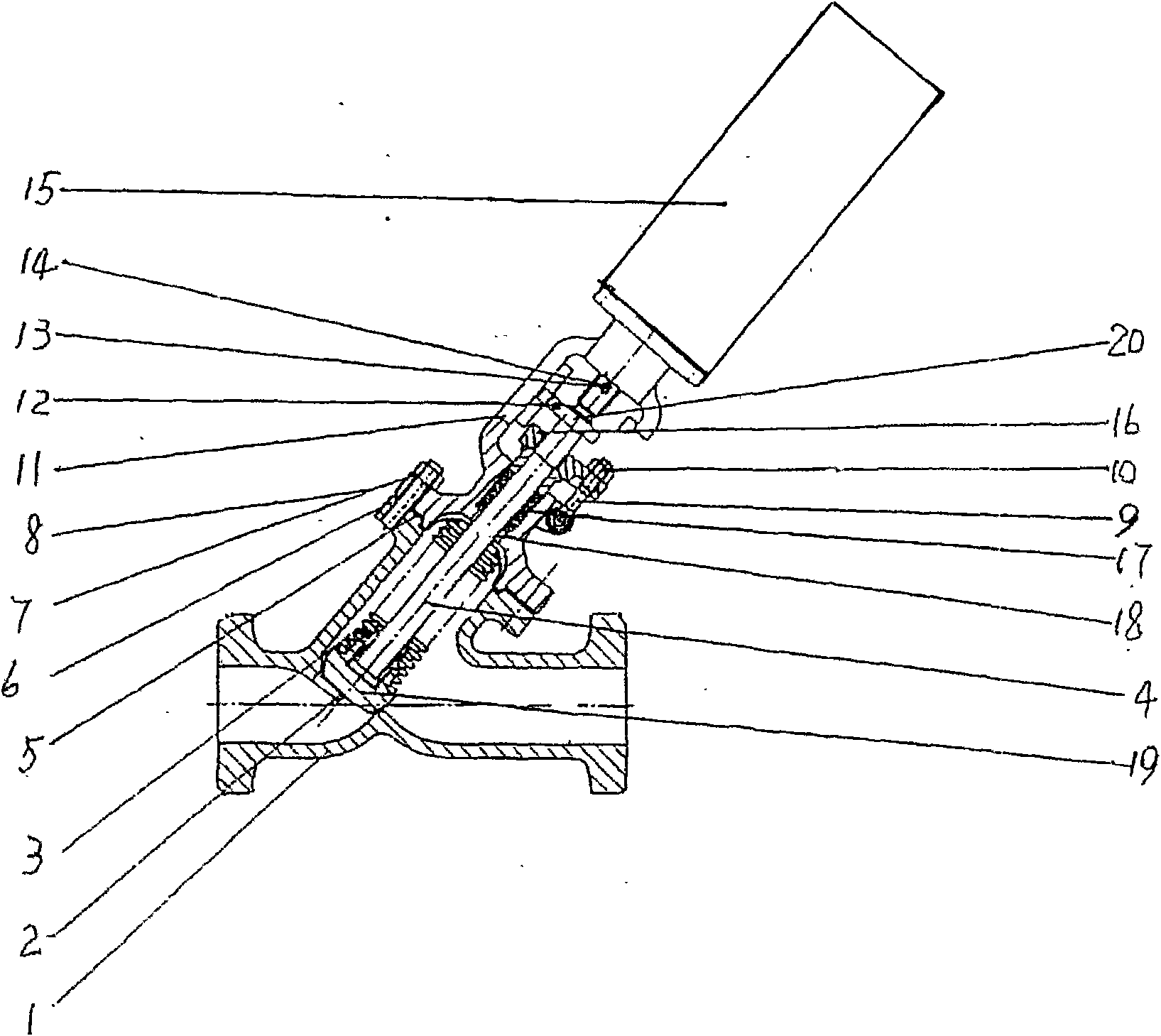

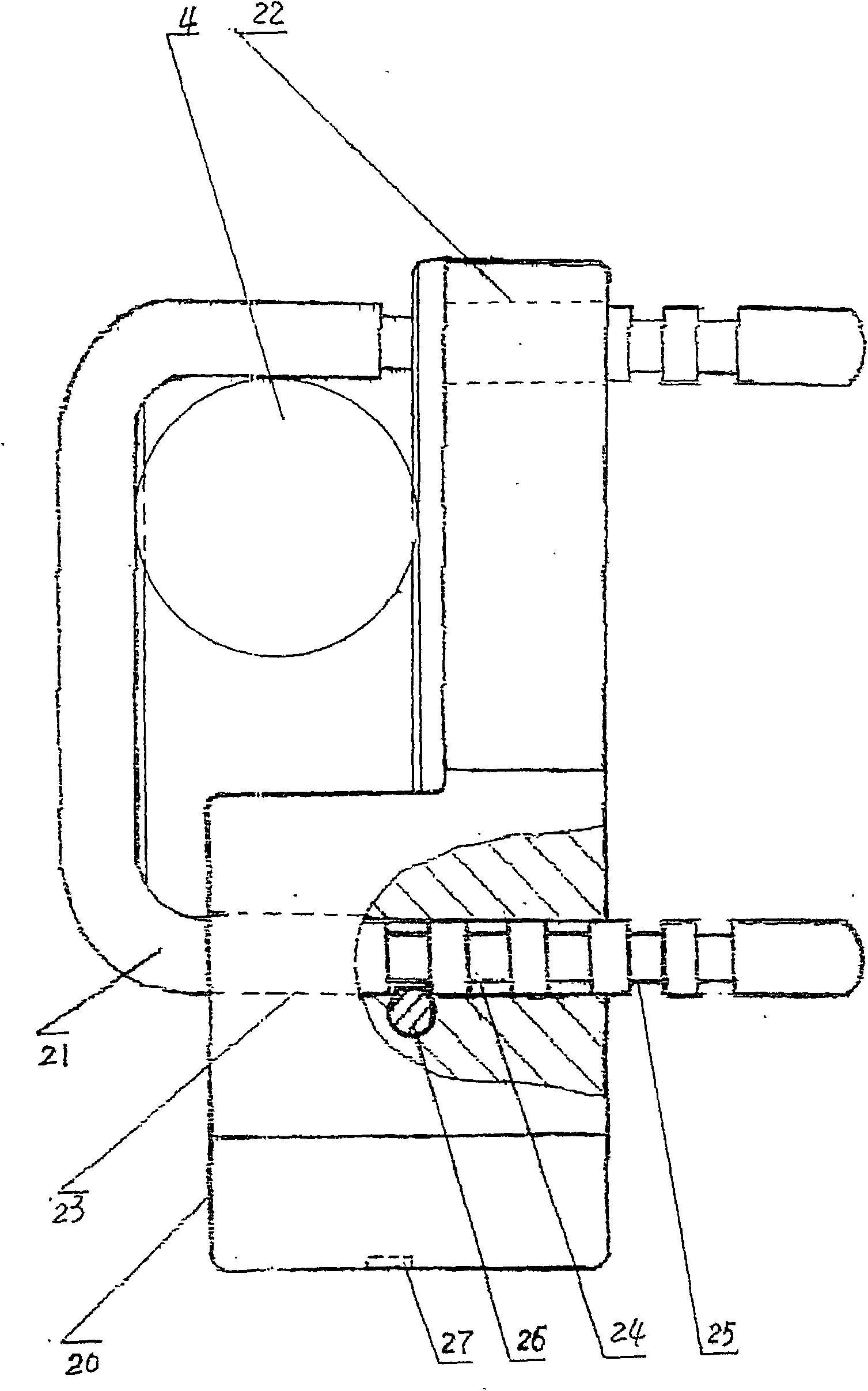

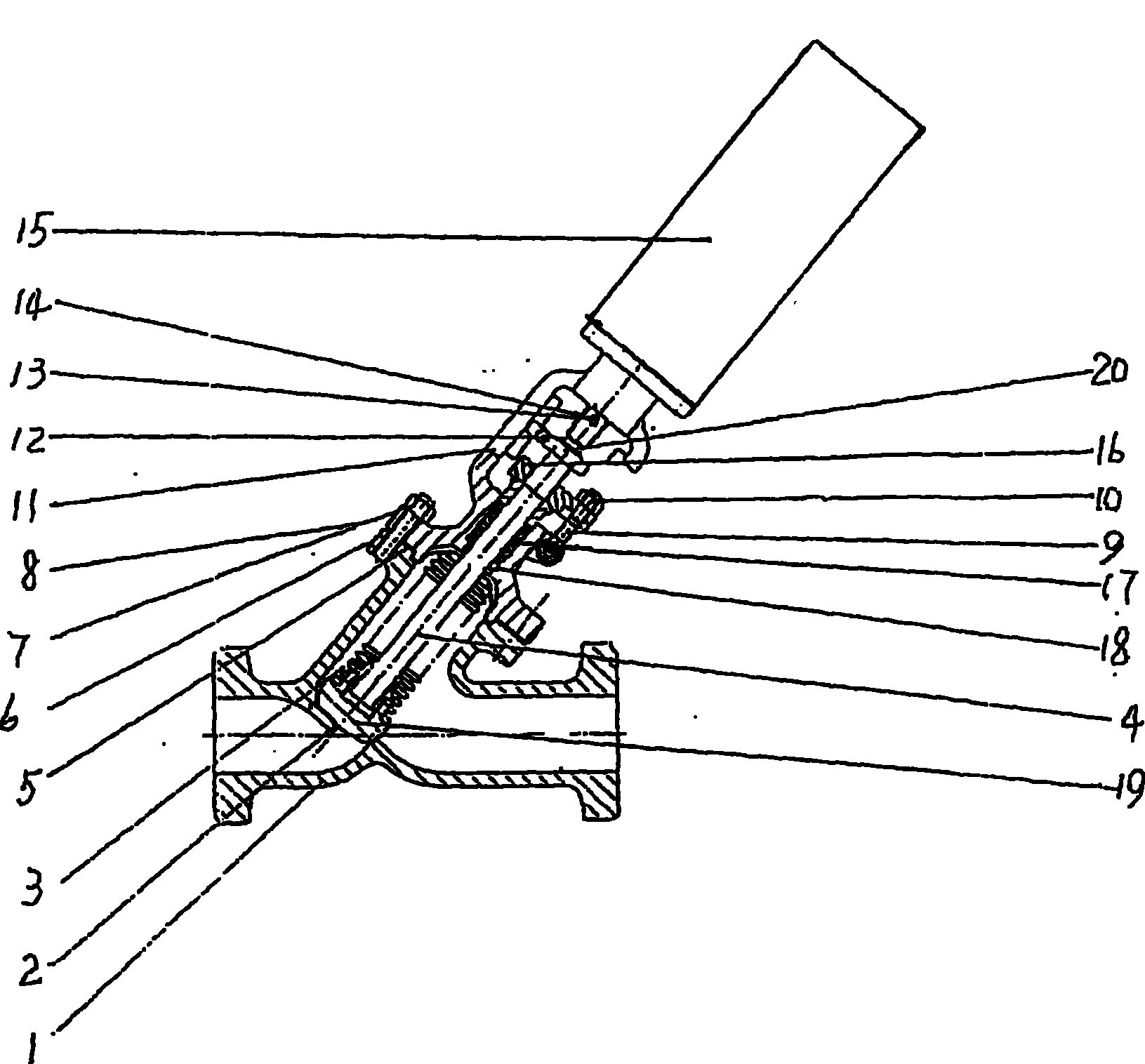

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0009] In the figure: 1. Inclined valve body, 2. Overlay welding Co-based hard alloy sealing ring, 3. Titanium-plated austenitic stainless steel bellows device, 4. Valve stem, 5. Gasket, 6. Bolt, 7 .Spring washer, 8. Nut, 9. Jack screw, 10. Jack nut, 11. Valve cover, 12 Pneumatic head mandrel sleeve, 13. Pneumatic head mandrel, 14. Pneumatic head mandrel sleeve cross pin, 15. Pneumatic head device, 16. packing gland, 17. packing, 18. lower packing pad, 19. valve disc. 20 lock bodies, 21 lock beams, 22. lock handle holes, 23. lock handles, 24 lock body holes, 25 lock beam grooves, 26 set screws, 27 keyholes.

[0010] In the example shown in the figure: Co-based hard alloy sealing ring 2 is surfacing on the inclined valve body 1, and Co-based hard alloy is surfacing on the sealing surface, which is wear-resistant, corrosion-resistant, anti-friction, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com