Compound underflow constructed wetland system

A constructed wetland system and wetland technology, which is applied in the field of compound subsurface constructed wetland system, can solve the problems of low biological nitrification and denitrification efficiency, unsatisfactory total nitrogen removal effect, and shortened wetland service life, etc. The effect of enhancing denitrification capacity and saving project expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

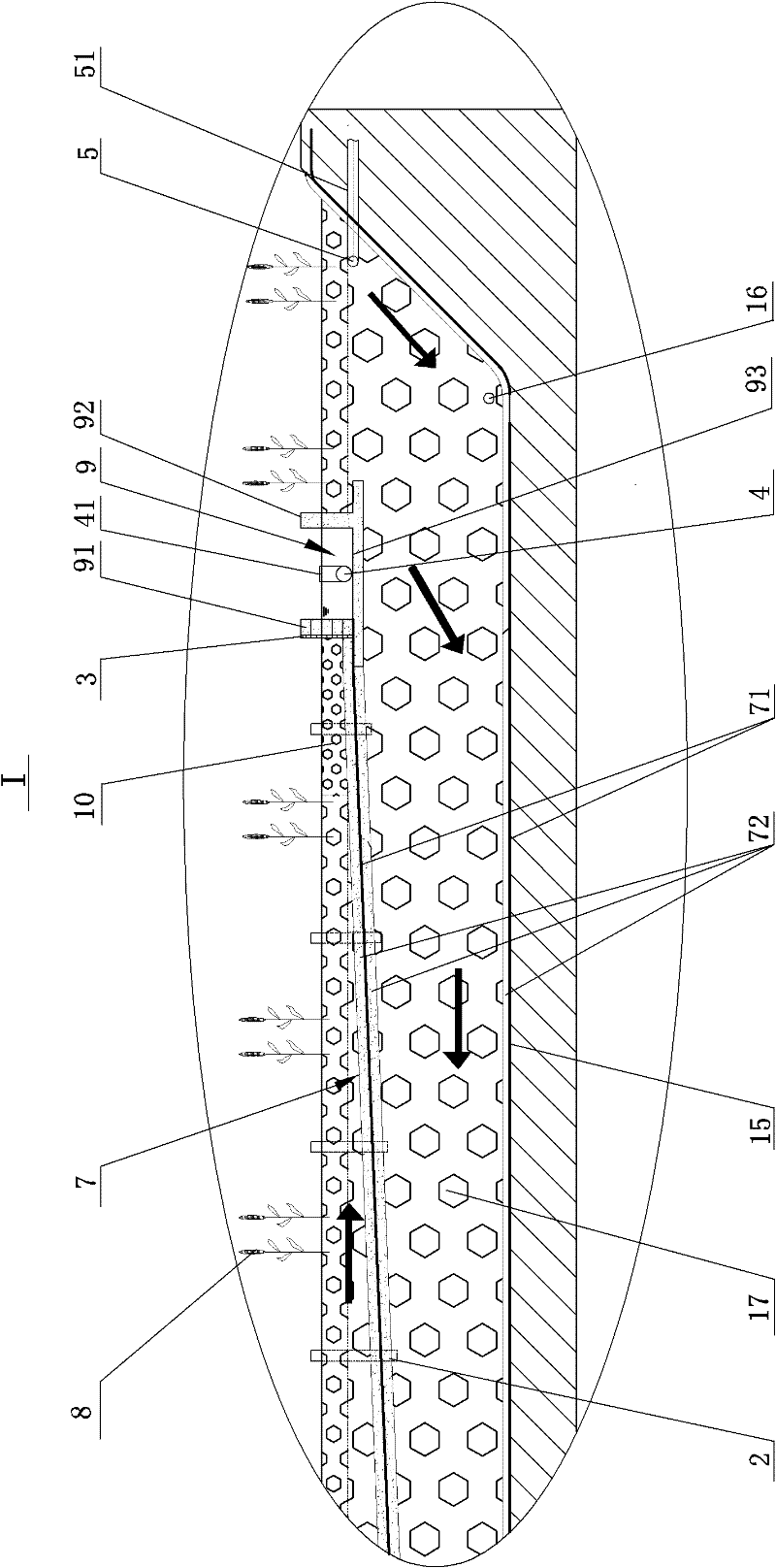

[0022] Figure 1-Figure 5 It shows a compound subsurface flow constructed wetland system, including a rectangular wetland pool 1 and a wetland bed 6 filled in the pool body. The above-mentioned wetland pool is composed of long side dams 11, 12 and short side dams 13, 14 surrounding the ground. The wetland pool It is the external support body of the whole wetland system, and its upper surface is paved with a geomembrane 71 for waterproofing. The surface of the geomembrane 71 is provided with a protective layer 72. The protective layer is a finely divided filler layer with a particle size of 5-10mm. The thickness of the finely divided filler layer is in accordance with the civil engineering industry. Sure. The surface layer of the above-mentioned wetland bed body 6 is a small particle diameter filler layer 61 , and the surface layer to the pool bottom 15 is a large particle diameter filler layer 62 . Small particle size, large particle size filler and finely crushed filler gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com