Measurement method and system for determining position of crane hook

A measurement system and measurement method technology, applied in the field of measurement, can solve problems such as few measurement parameters and complex systems, and achieve the effects of reducing the difficulty of calculation, simplifying the transfer function, and reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

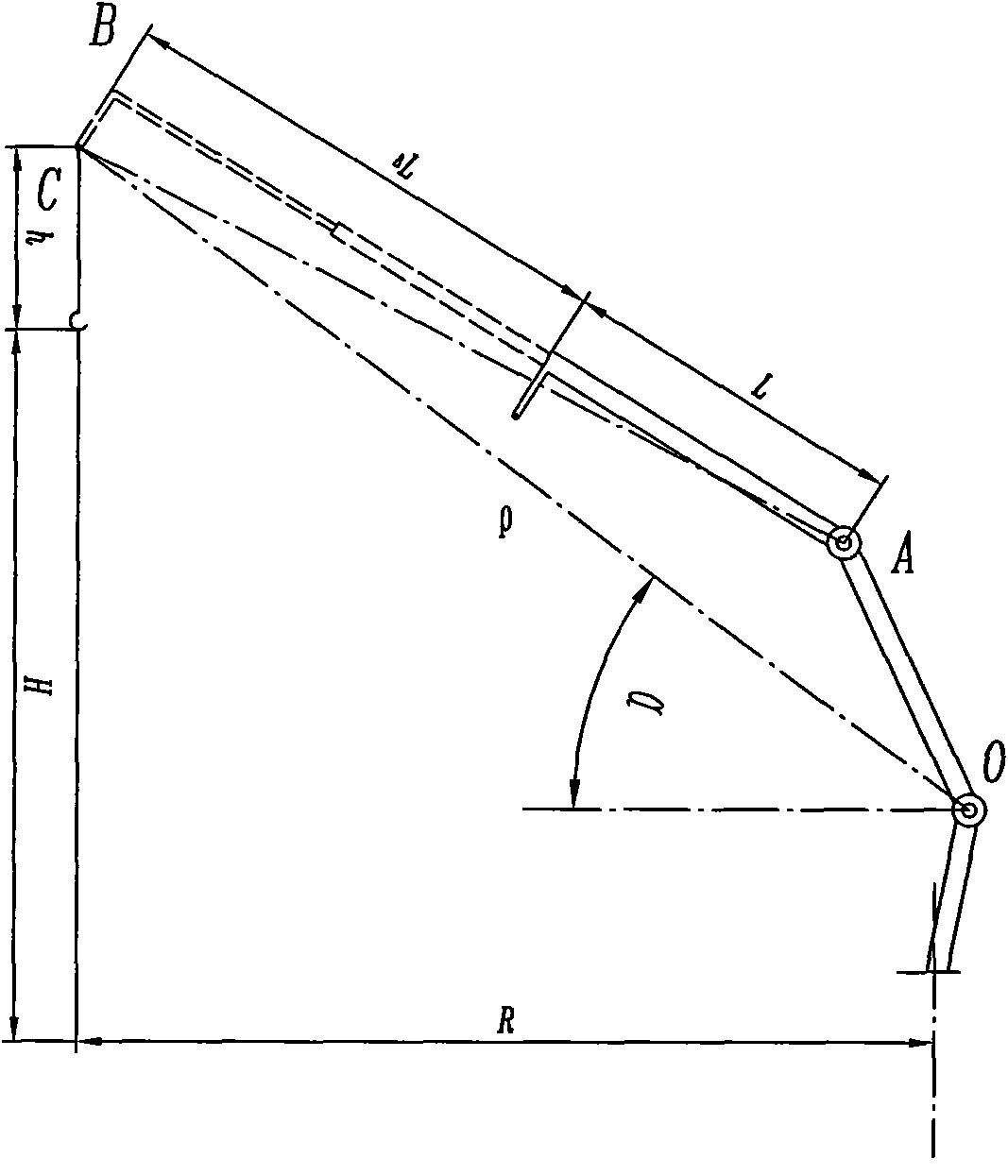

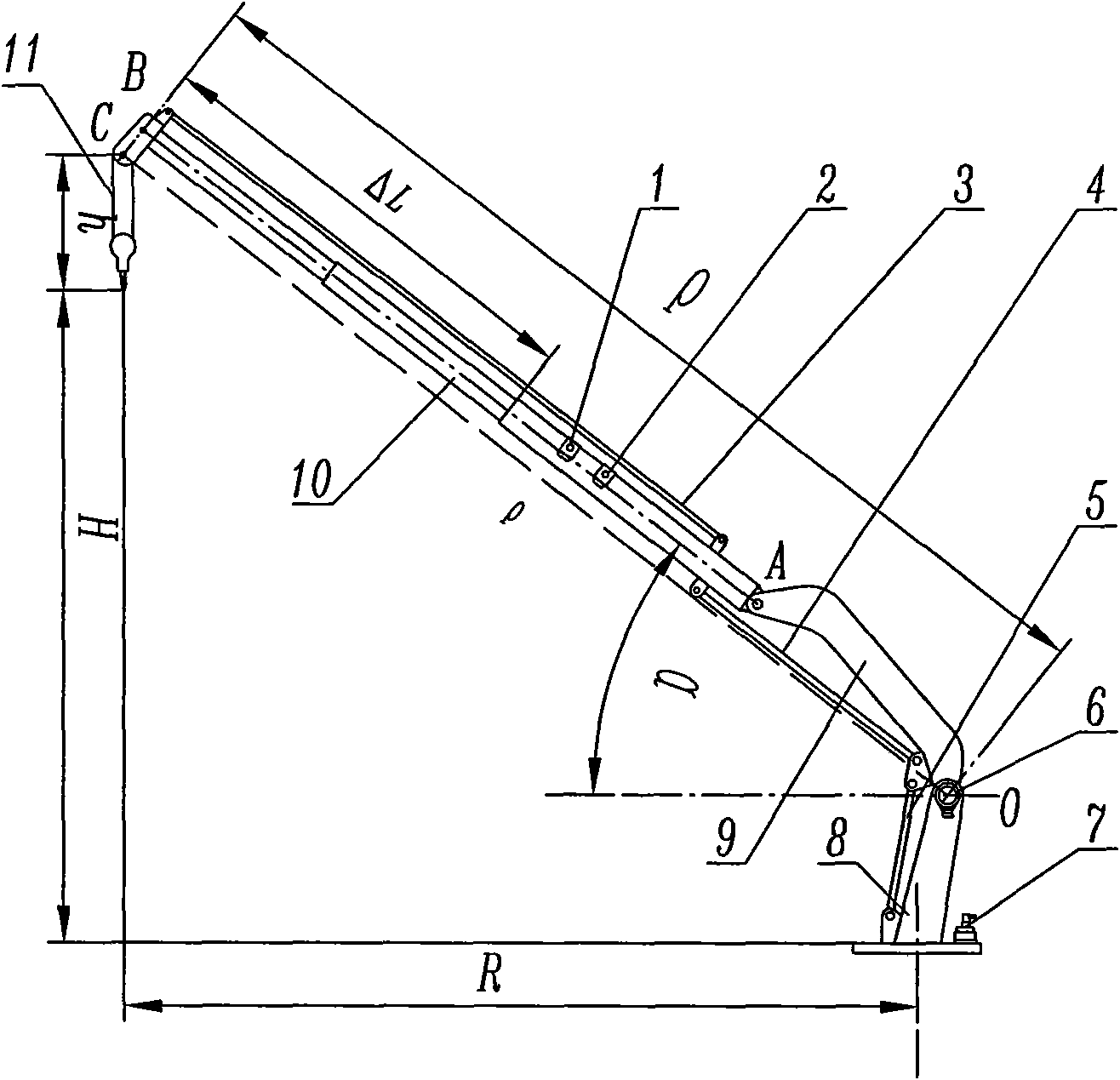

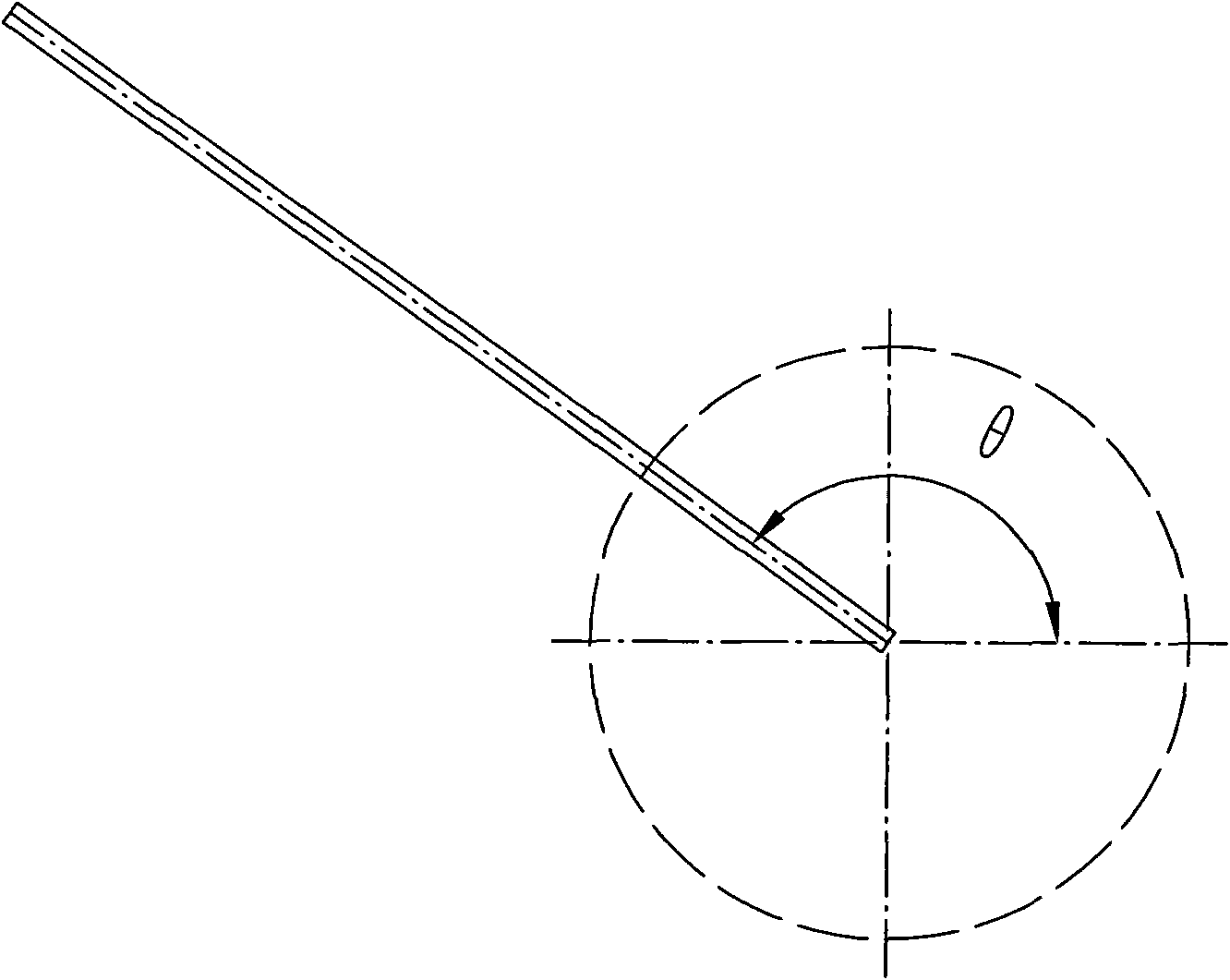

[0020] like figure 1 As shown, in order to accurately track and measure the position of the lifting load, generally speaking, the real-time working range R of the hook, the lifting height H and the rotation angle θ of the turntable must be determined. The spherical coordinate system is established with the hinge point center of the folding arm and the turntable as the coordinate origin O, the coordinate radius ρ is the line connecting the origin O and the center point C of the fixed pulley at the hook, and the angle between the coordinate radius ρ and the horizontal plane is the measurement argument α, the storage state of the crane is the azimuth zero angle, and its turning angle is the azimuth angle θ. By controlling these three parameters, the hook can be controlled to be directly above the specified position. The displacement h of the movable pulley moving up and down represents the height of the hook, and controlling h can control the loading or lifting of the lifting loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com