Assembling and manufacturing method for body of carrier roller of belt conveyor

A manufacturing method and a technology of a belt conveyor, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of unable to improve production efficiency, many processes, increase production costs, etc., achieve a firm and reliable assembly structure, and use less process equipment , The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

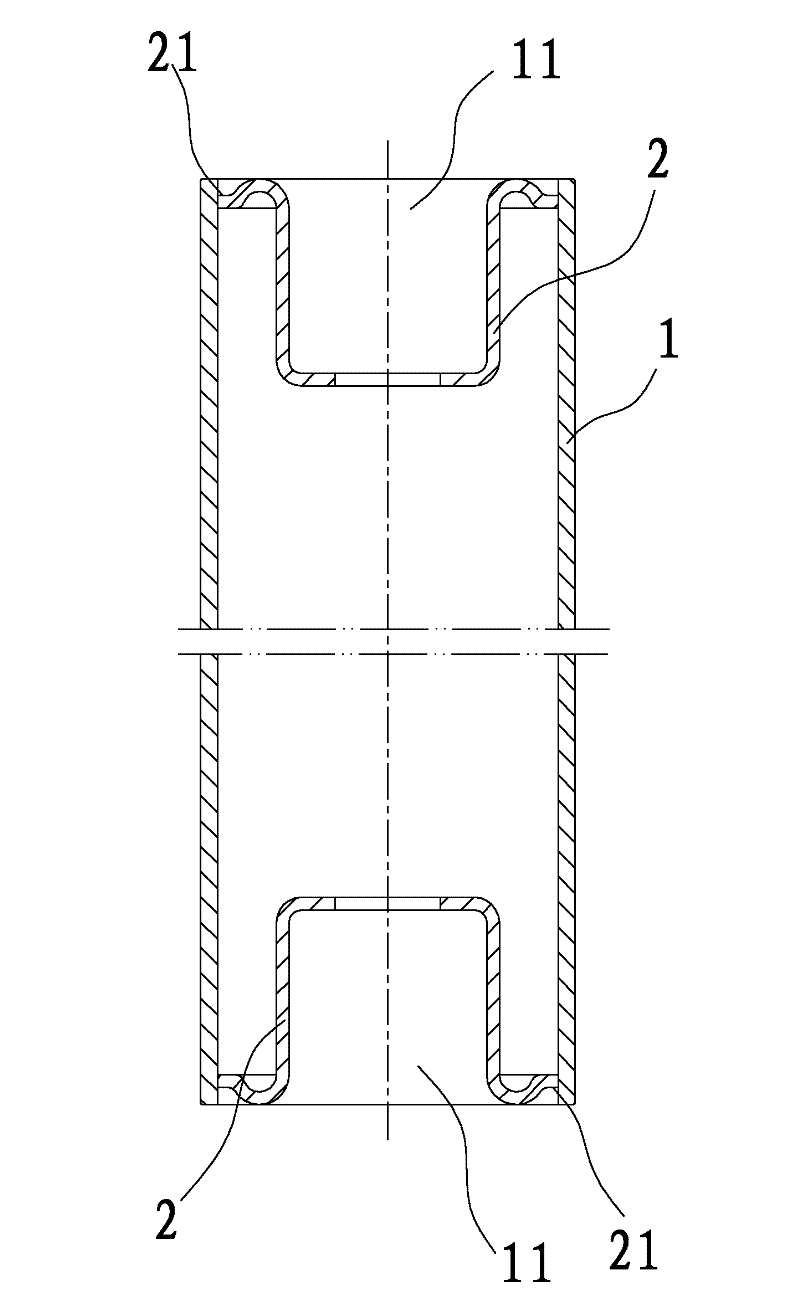

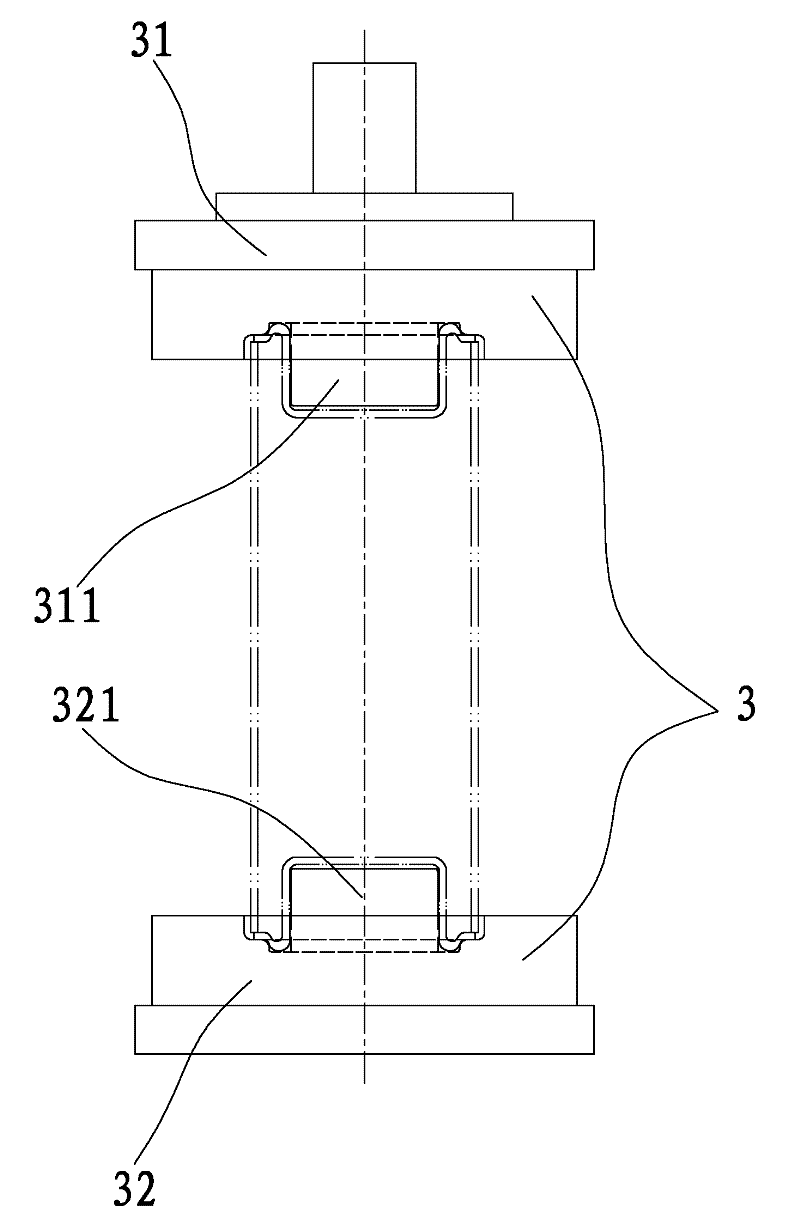

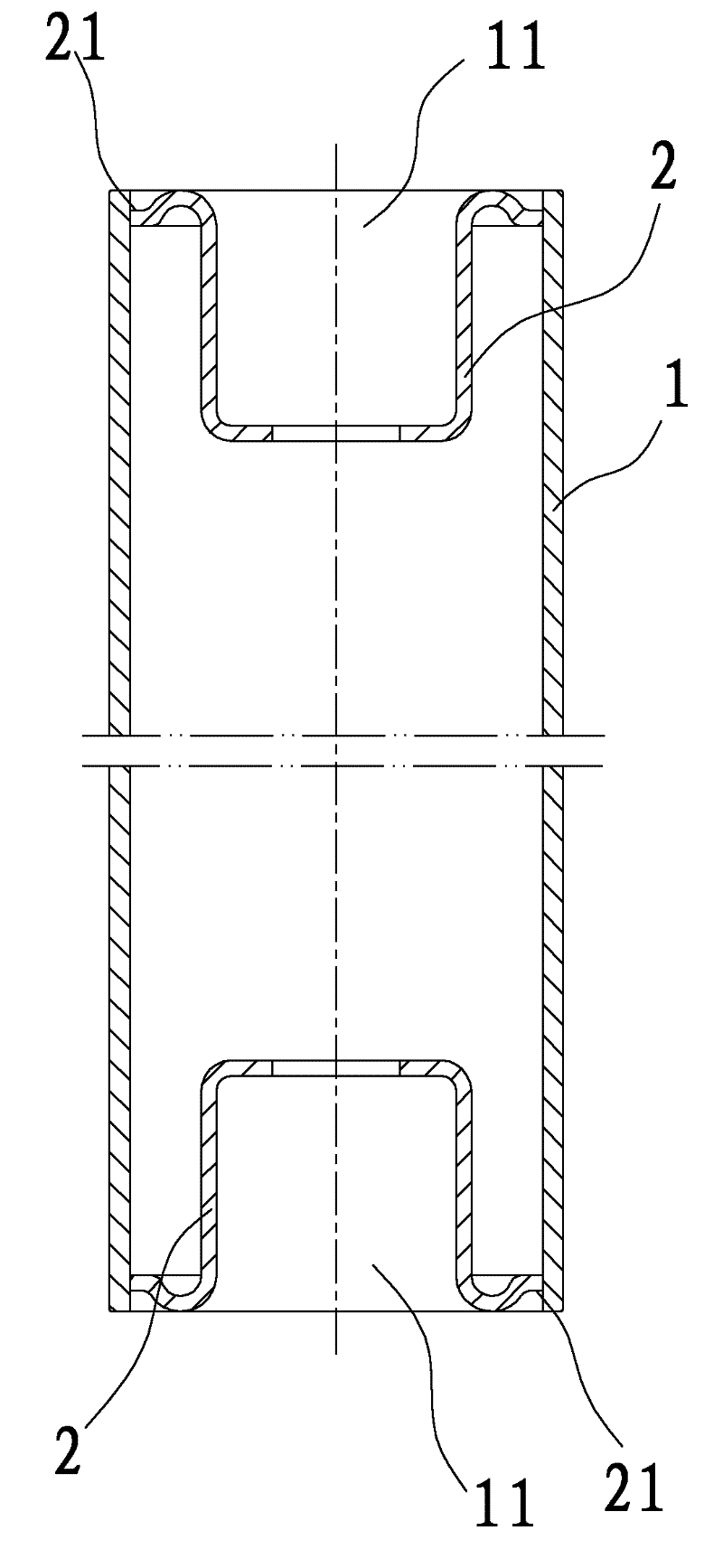

[0015] Such as figure 1 , figure 2 Shown is an assembly and manufacturing method for belt conveyor idler roller bodies provided by the present invention with simpler assembly and manufacturing procedures, less process equipment and high production efficiency. The assembly manufacturing method includes the following process steps,

[0016] First, the roll skin is blanked to make a roll skin 1; then, according to the size of the mounting hole 11 at the end of the qualified roll skin 1, the bearing seat 2 is processed so that the outer diameter of the mounting plate 21 of the bearing seat 2 is larger than the roll skin. 1 The inner diameter of the mounting hole 11 at the end has an assembly interference; then the two bearing seats 2 are pressed into the mounting holes 11 at both ends of the roller skin 1 at the same time with an external force, thus completing the roller body of the belt conveyor roller The processing and manufacture of the roller body form the interference fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com