Comb type mixing nozzle of injection molding machine

An injection molding machine and comb-type technology, which is applied in the field of comb-type mixing nozzles, can solve the problems of lower assembly efficiency, assembly trouble, and cost increase, and achieve the effects of improved assembly efficiency, convenient maintenance, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

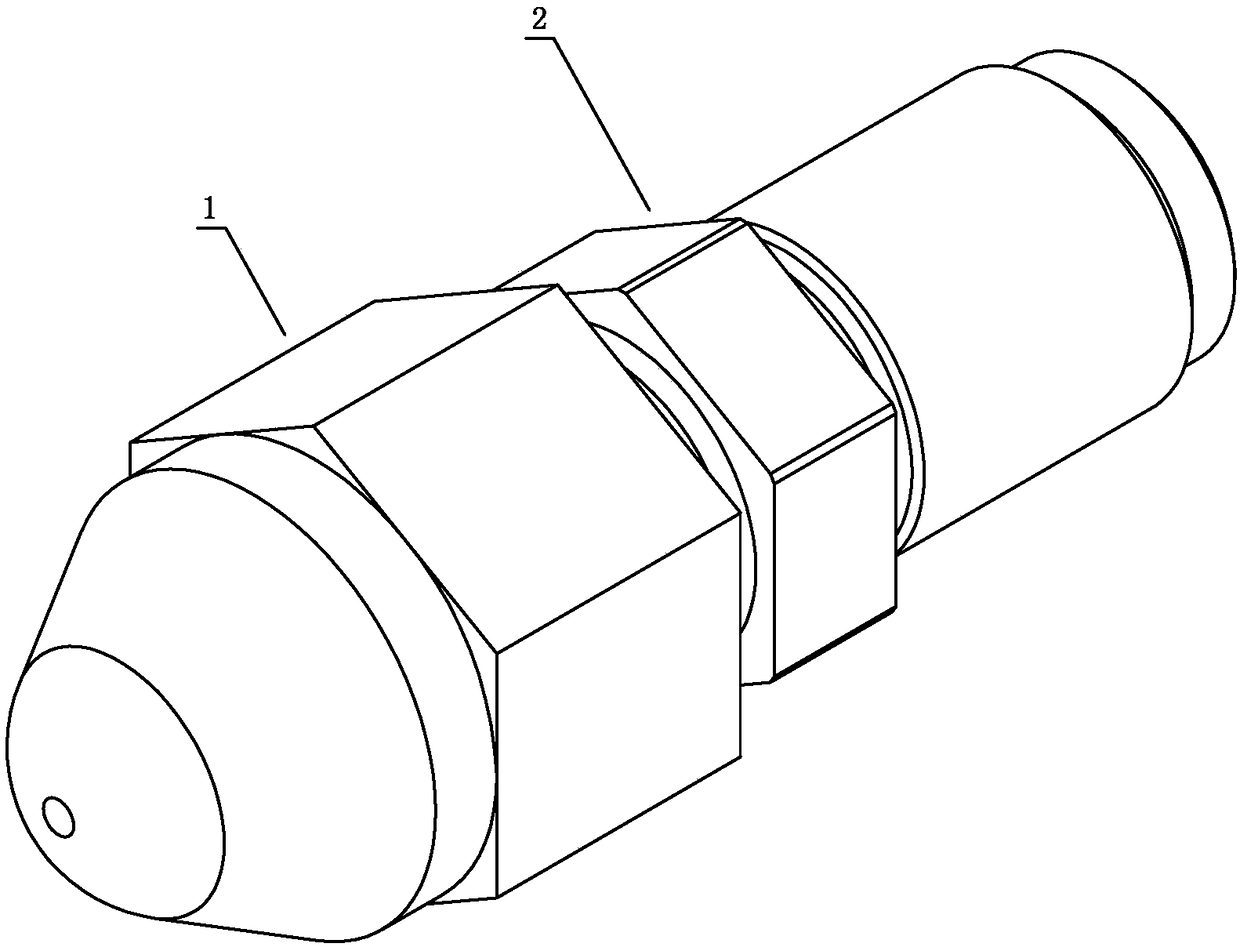

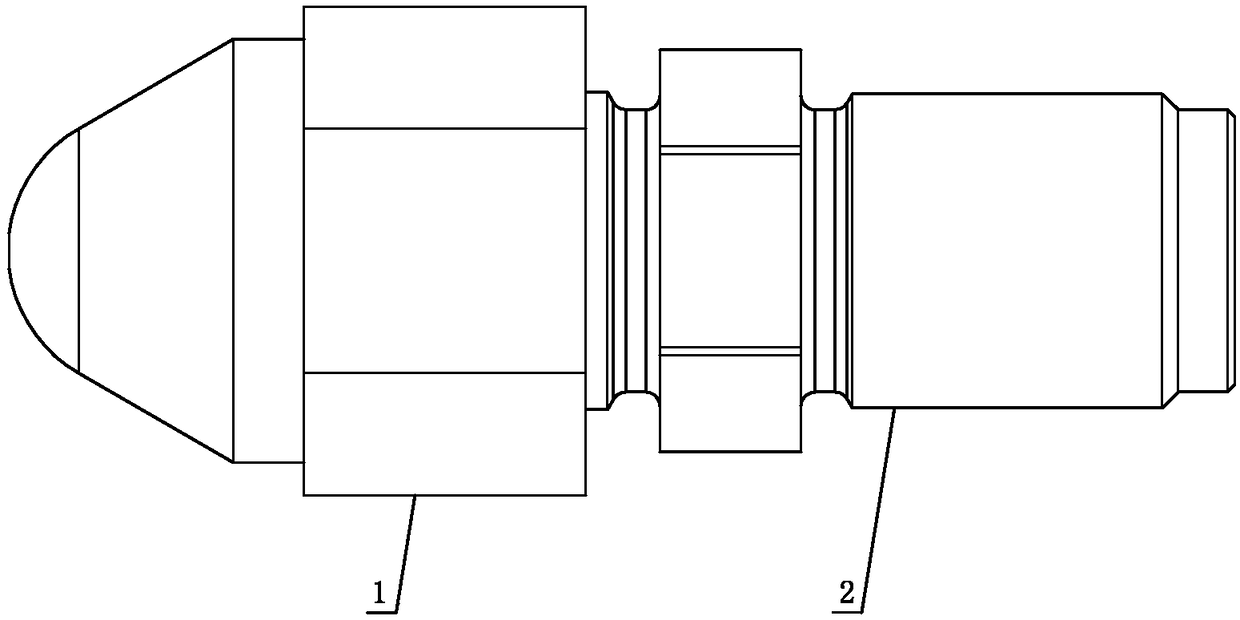

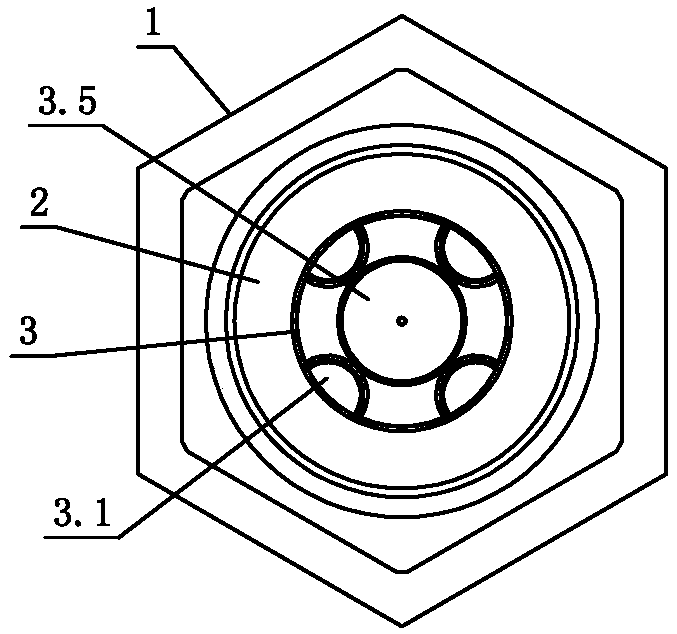

[0040] see Figure 1-Figure 21 The comb-shaped mixing nozzle of this injection molding machine includes a nozzle head 1 and a nozzle body 2 connected to each other. The inner cavity of the nozzle body 2 is provided with a comb-shaped mixing part 3. The comb-shaped mixing part 3 is a columnar body, and its surface There are two feed channels 3.1 and two discharge channels 3.4; one end of the feed channel 3.1 is closed and the other end is open, and it runs through to the feed end of the comb-shaped mixing part 3. The open end of the feed channel 3.1 is connected to the The inner cavity of the nozzle body 2 is directly connected; one end of the discharge channel 3.4 is closed and the other end is open, and it runs through to the discharge end of the comb-shaped mixing part 3, and the open end of the discharge channel 3.4 is directly connected to the inner cavity of the nozzle head 1 ; There is a glue comb structure between the feed channel 3.1 and the discharge channel 3.4, and ...

no. 2 example

[0048] see Figure 22-Figure 24 , the comb-shaped mixing nozzle of this injection molding machine is different from the first embodiment in that: the nozzle head 1 is a through structure, and its inner wall is provided with a second limiting boss 1.3, and the comb-shaped mixing part 3 is arranged on the nozzle head 1 The inner cavity, the second limiting boss 1.3 the discharge end of the comb-shaped mixing part 3; the outer wall of the nozzle head 1 is provided with the second external thread 1.4, the inner wall of the nozzle body 2 is provided with the second internal thread 2.4, the nozzle The body 2 and the nozzle head 1 are screwed to each other through the internal and external threads 2.3; the end of the nozzle head 1 is provided with a second connecting shaft 1.5, and the inner wall of the nozzle body 2 is provided with a second connection hole 2.5, when the nozzle body 2 and the nozzle head 1 are connected , the second connecting hole 2.5 and the second connecting shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com