Cyclone separation device for preventing dust backflow

A technology of cyclone separation device and cyclone separator, which is applied in the direction of cyclone device, the device whose axial direction of the cyclone can be reversed, suction filter, etc., can solve the problems of difficult dust collection and limited dust collection efficiency, and achieve compact structure , saving space, and beneficial to the design of the internal flow channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below with reference to the drawings and examples.

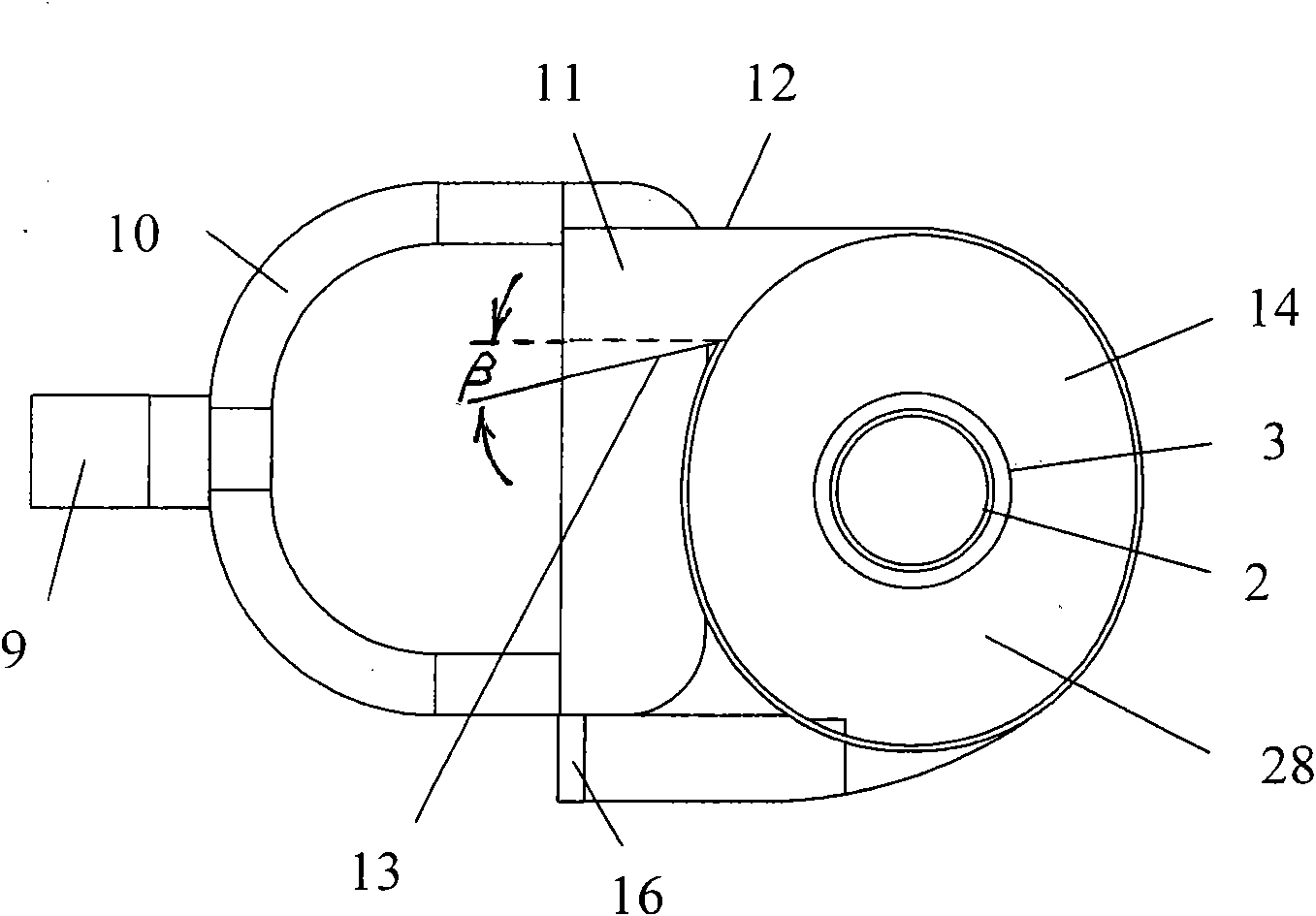

[0049] figure 2 It is a perspective view of the cyclone separation device embodiment 1 of the present invention; image 3 It is a top view of cyclone separation device embodiment 1 of the present invention; Figure 4 It is a perspective view of the dust collecting box when the cover of the dust collecting box of the present invention is opened.

[0050] The present invention prevents the cyclone separation device of dust backflow, such as figure 2 , image 3 , Figure 4 Shown, the present invention prevents the cyclone separating device of dust backflow, and it is made of the bucket-shaped dust collecting box 10 that has handle 9, oval cyclone separator 14, the conical filter 2 that is contained in the cyclone separator.

[0051]The dust collection box is a box body composed of an outer wall 22, a front wall 23, a bottom 21 and a top 19. The front wall opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com