Method for detecting cleanness of multiple sampling points automatically and continuously

A detection method and sampling point technology, which is applied in the direction of measuring devices, suspension and porous material analysis, particle suspension analysis, etc., to achieve the effect of improving the control level, increasing the difficulty of operation, and eliminating the probability of degradation or failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

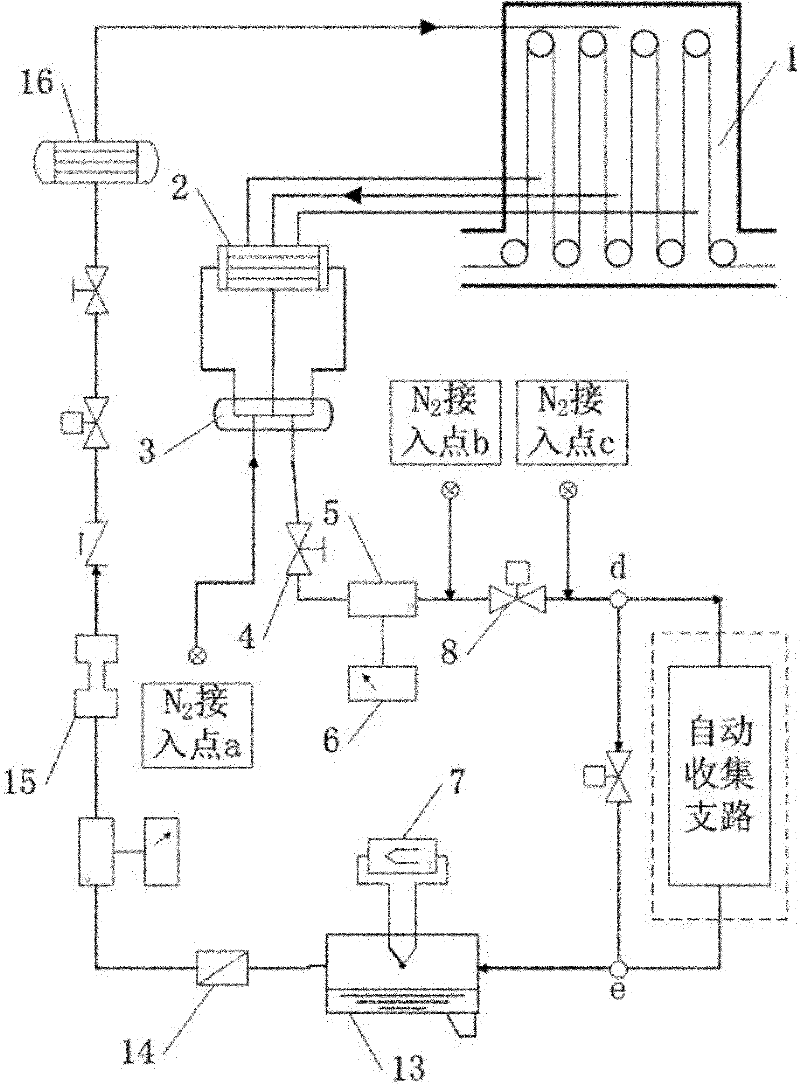

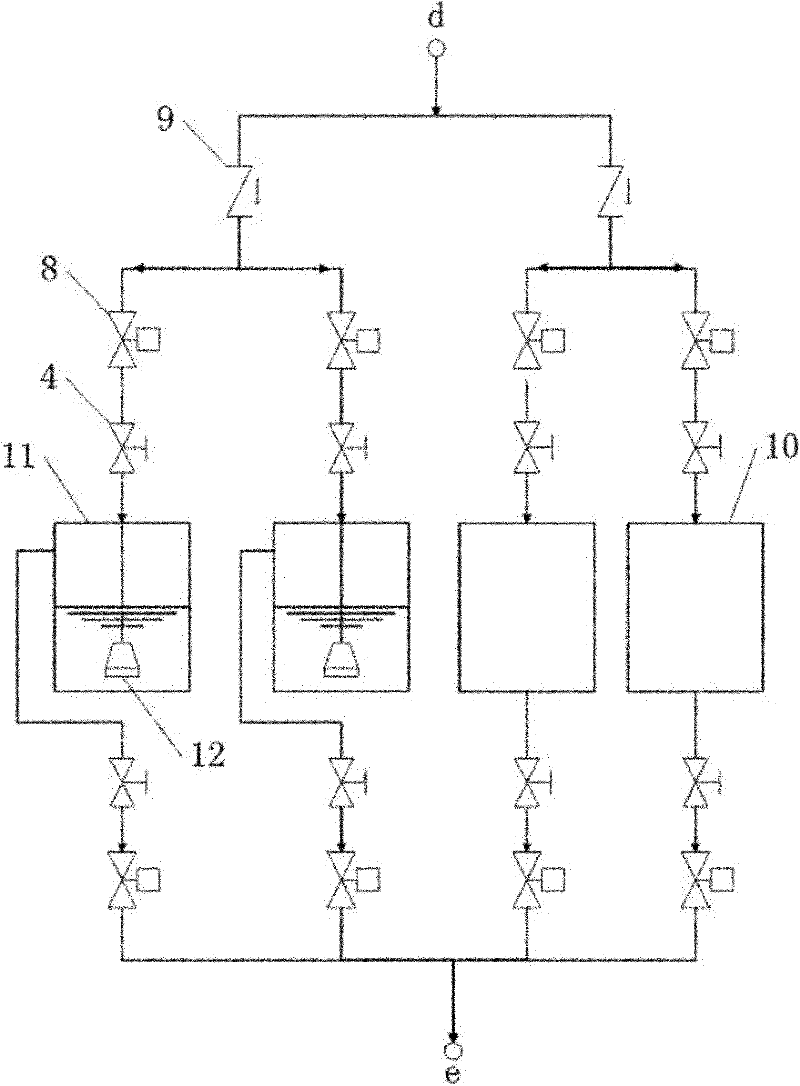

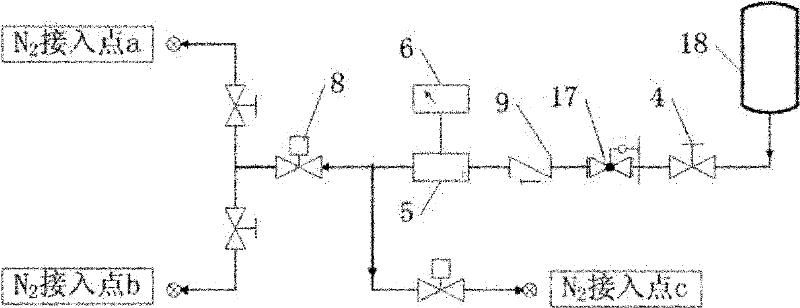

[0019] The automatic and continuous cleanliness detection method of multiple sampling points provided by the present invention is specifically: use a sampling metering pump to extract the gas in the furnace chamber of the annealing furnace, control the automatic switch valve in the continuous automatic collection branch to select the collector, and make the furnace gas According to the set flow through the currently selected collector, various particles in the furnace gas are blocked in the collector. The controller opens the collectors one by one according to the set order to realize continuous and automatic pollutant collection. The sampling metering pump will automatically measure the volume of the collected furnace gas for each sampling, and convert the volume unit into standard cubic meters according to the temperature and pressure measured by the instrument before the sampling metering pump. According to the weight difference of the filter element of the total pollutant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com