Sulphide stress corrosion uniaxial tensile test loading detection method and monitoring system thereof

A technology of stress corrosion and uniaxial stretching, applied in the direction of applying stable tension/pressure to test material strength, measuring force, measuring device, etc., can solve difficult stress conditions, affect test accuracy, and large cumulative error of the system, etc. problem, to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

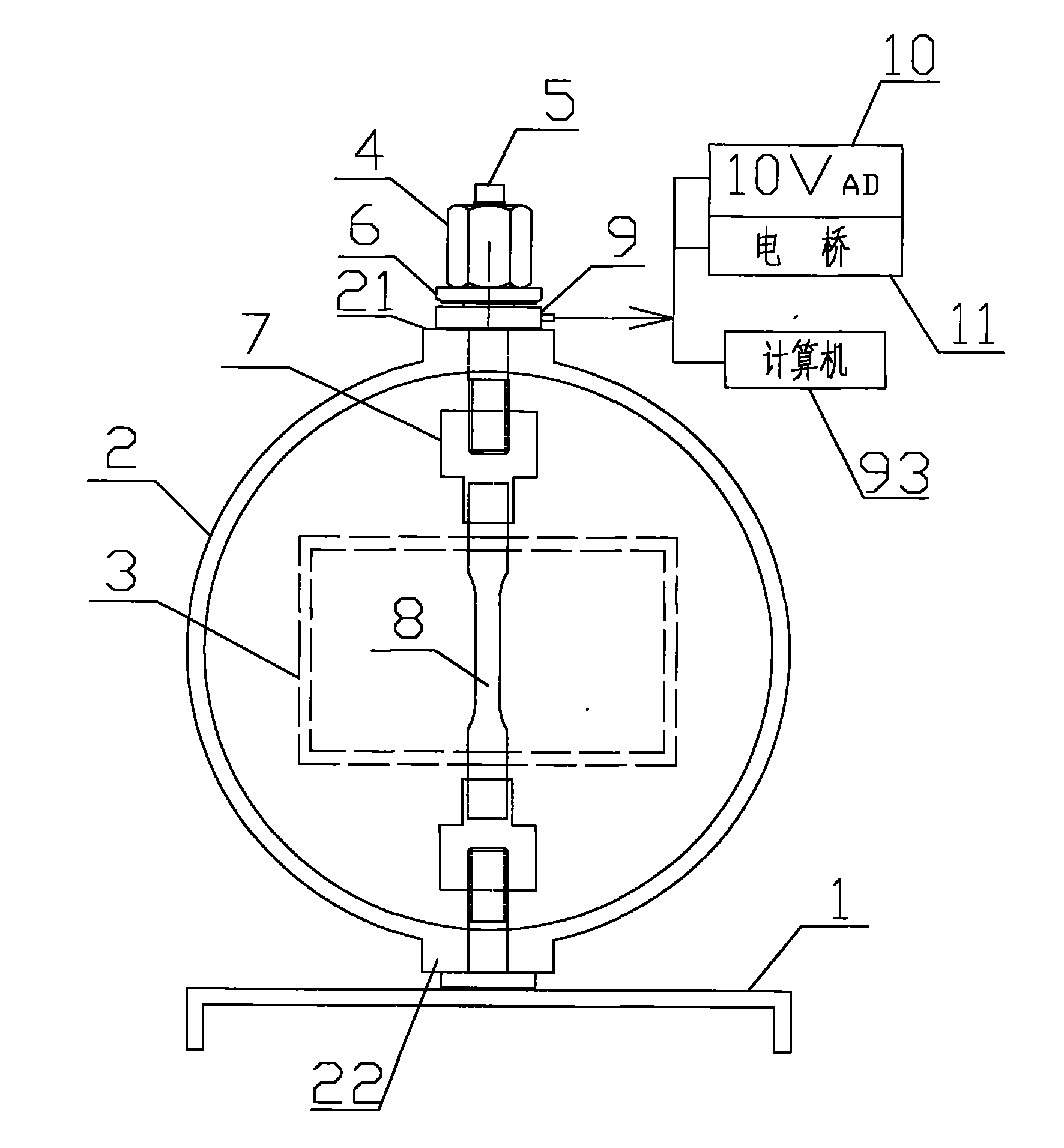

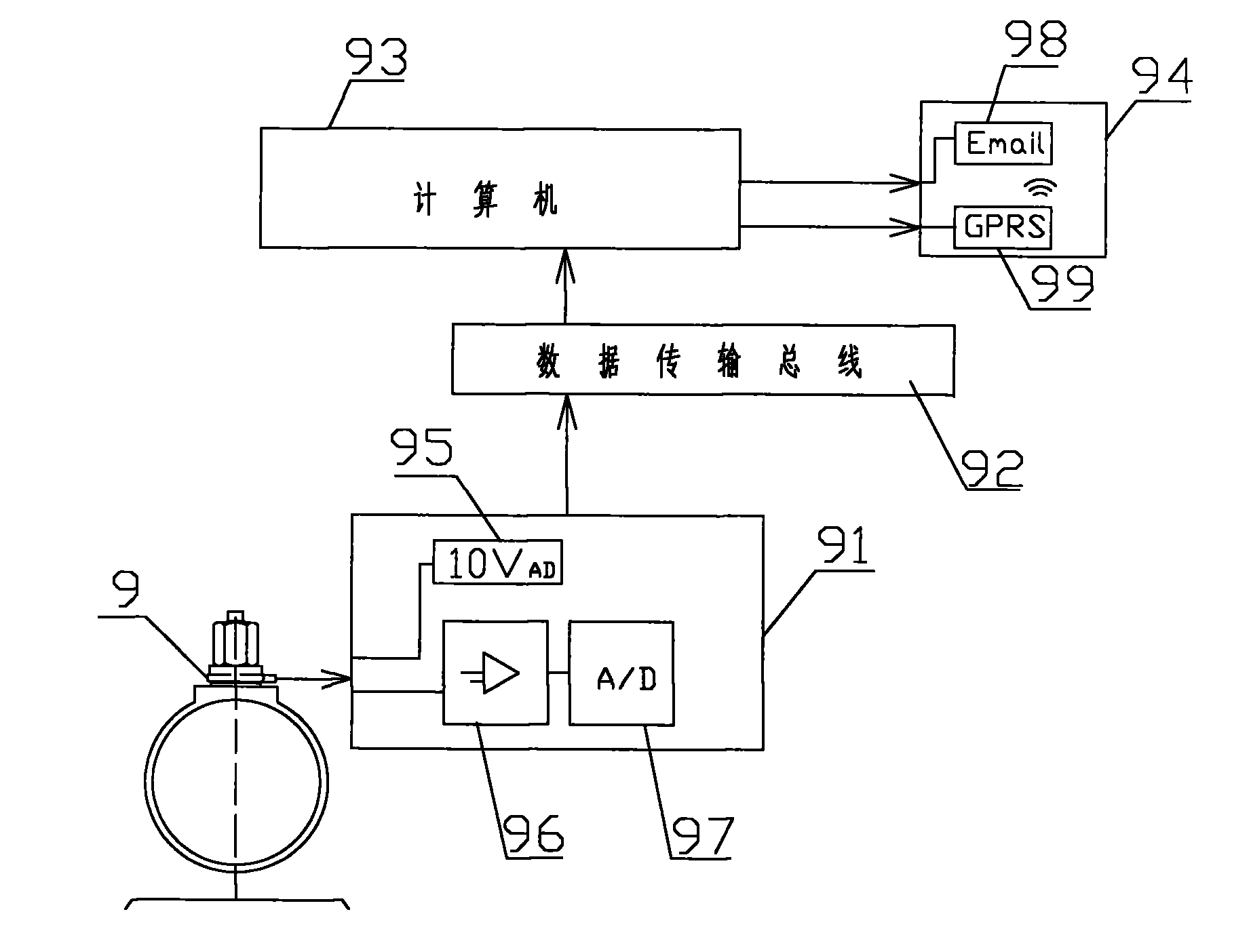

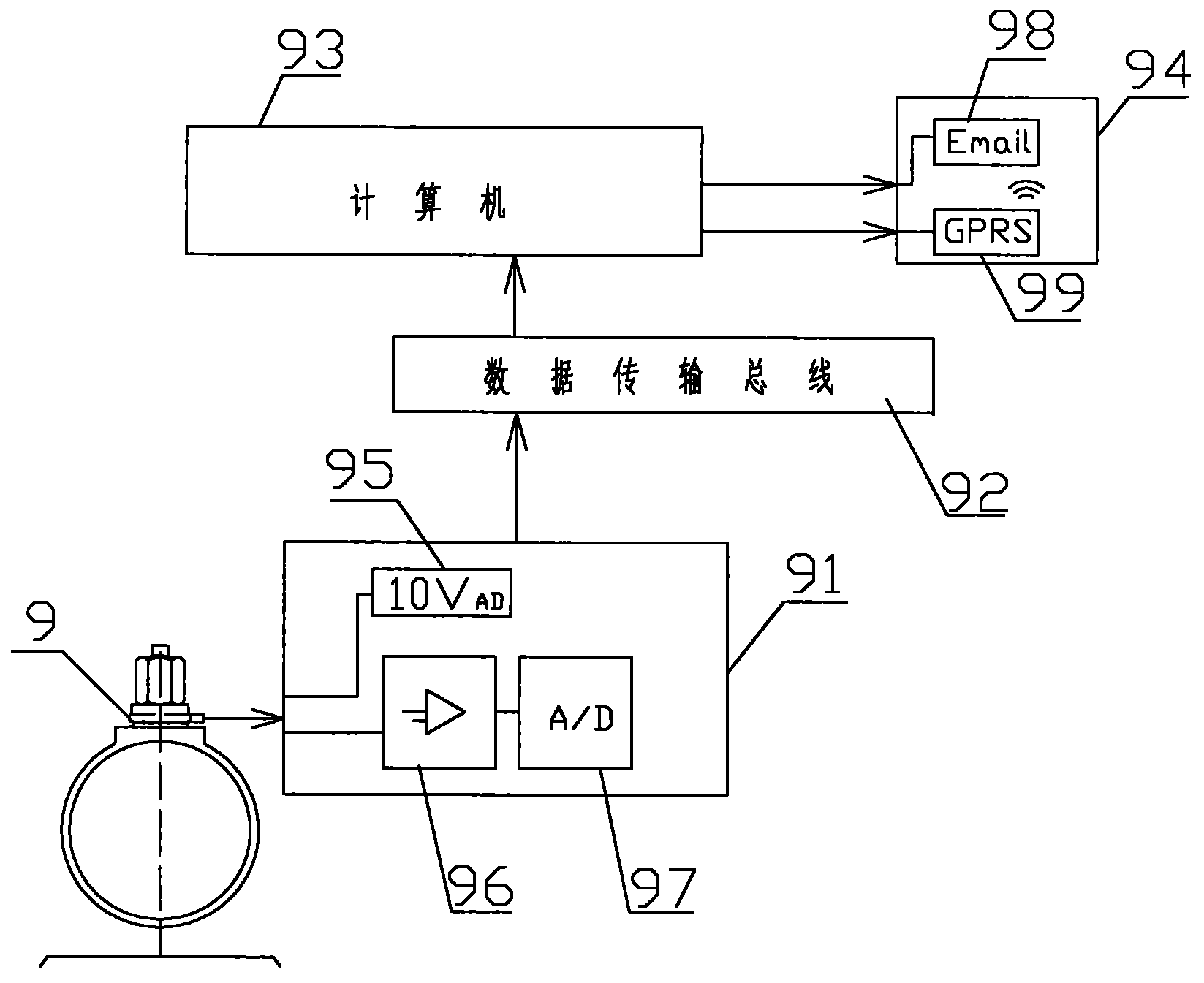

[0016] Such as figure 1 As shown, the loading detection method of the sulfide stress corrosion uniaxial tensile test of the present invention is: add a ring between the thrust bearing 6 under the loading nut 4 of the stress corrosion tensile test equipment and the upper platform 21 of the stress ring 2 The load sensor 9, the loading screw 5 passes through the load sensor 9 and the upper platform 21 of the stress ring 2 and then connects to the sample chuck 7, the sample chuck 7 clamps the sample 8, and the sample 8 is placed in the sulfide medium container 3 Inside, the lower platform 22 of the stress ring 2 is fixed on the base 1; when the loading nut 4 is tightened on the loading screw 5, a tensile force is applied to the sample 8, and the load sensor 9 directly detects the compression applied by the loading nut 4 to the load sensor 9 The compressive force is equal to the tensile load applied to the sample 8, so as to accurately detect the load borne by the sample in the sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com