Vertical precombustion furnace, horizontal rotary furnace and vertical discharging device combined garbage incinerator

A waste incinerator and rotary furnace technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of large floor area, high construction cost, and large heat loss of the system, so as to ensure sealing and relative rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

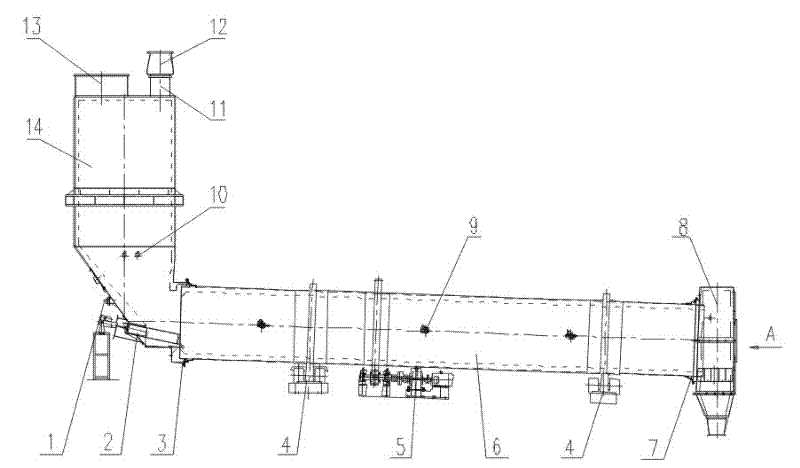

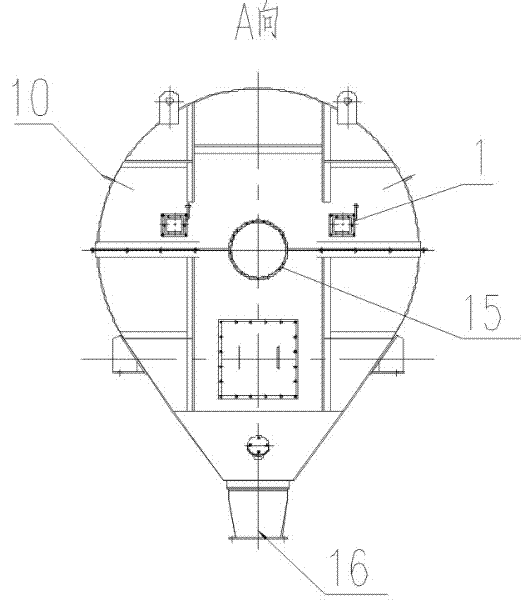

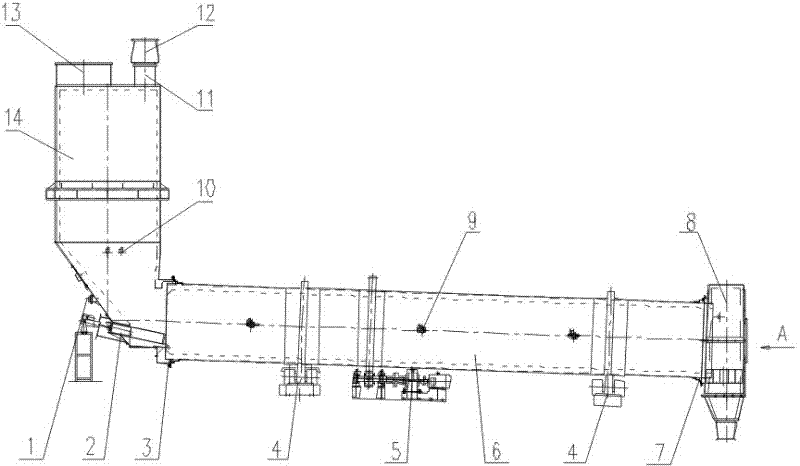

[0036] Combine figure 1 , The vertical pre-combustion furnace + horizontal rotary furnace + vertical discharger combined waste incinerator of the present invention, the basic composition of the waste incinerator includes vertical pre-combustion furnace 14, horizontal rotary furnace 6 and vertical discharge The discharge port of the vertical pre-combustion furnace 14 is connected to the feed port of the horizontal rotary kiln 6 through the kiln head rotary sealing device 3, and the discharge port of the horizontal rotary kiln 6 is connected to the kiln end rotary sealing device 7 The vertical discharger 8 is connected, and the central axis of the furnace body of the horizontal rotary furnace 6 has a downward inclination of 3 to 5°, supported by the supporting device 4, and the rotation of the horizontal rotary furnace 6 is implemented by the transmission device 5.

[0037] The structural design of the vertical pre-burner 14 partially absorbs the structural characteristics of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com