Connection method of ultrahigh molecular weight polyethylene pipelines

A technology of ultra-high molecular weight and connection method, which is applied in the field of connection of ultra-high molecular weight polyethylene pipes, can solve problems such as the sealing of unfavorable pipe joints, achieve the effects of improving on-site installation speed, facilitating anti-corrosion treatment, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

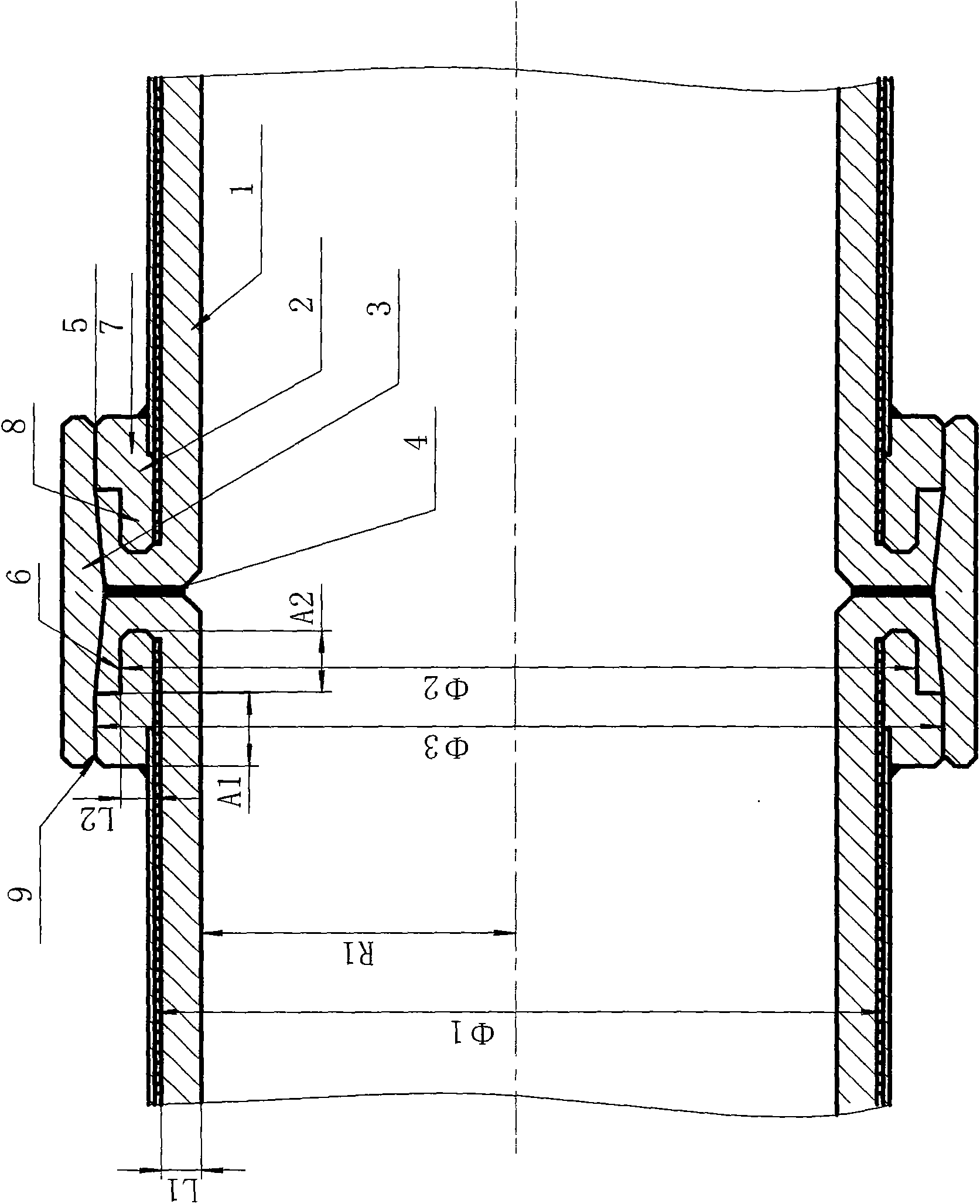

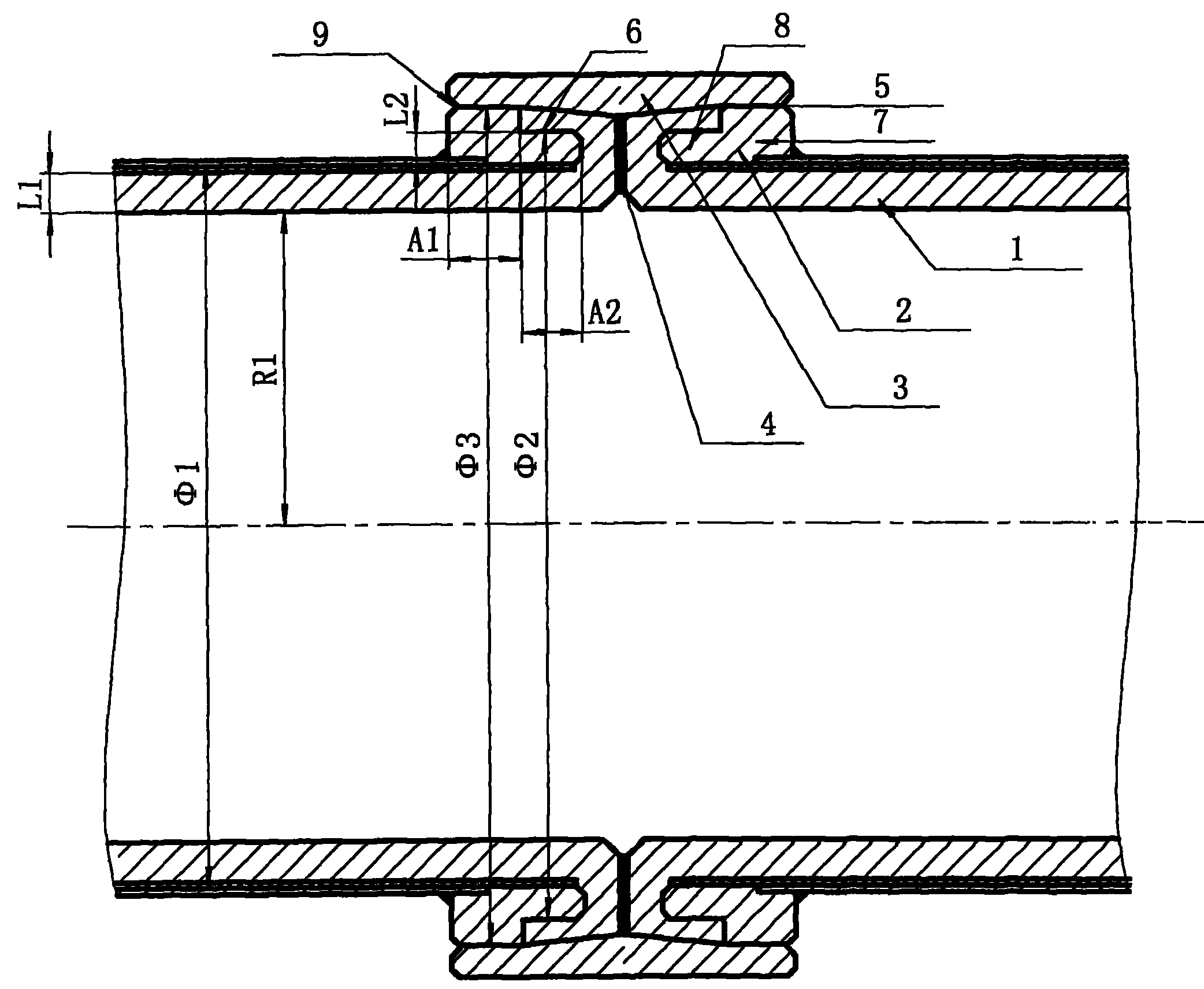

[0030] See attached picture,

[0031] The inner diameter shown in the first embodiment of the present invention is 2R 1 , wall thickness L 1 , the outer diameter is Φ 1 =2(R 1 +L 1 ) The connection method of the ultra-high molecular weight polyethylene pipeline, comprising the following steps:

[0032] 1. Prepare special-shaped steel rings and steel sleeves with the following structures for use:

[0033] Steel ring: It is an integral structure composed of two parts with the same inner diameter and different wall thickness. Its inner diameter is 2 mm larger than the outer diameter of UHMWPE pipe, and the inner ring of the steel ring is at the smaller wall thickness. Its outer diameter is Φ 2 2(R1+L1+L2+2mm), the width of the inner ring of the steel ring is A 2 , which is the UHMWPE pipe wall thickness L 1 2.5 times of that, the thicker part is the outer ring of the steel ring, and its outer diameter is Φ 3 2 (R1+2L1+L2+2mm), the width of the outer ring of the steel ring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com