Novel pasting combined type drainage structural member

A drainage component and composite technology, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of reducing the drainage channel space, increasing the drying process, and increasing the production cost, so as to reduce the drainage resistance and improve the The effect of drainage flux, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

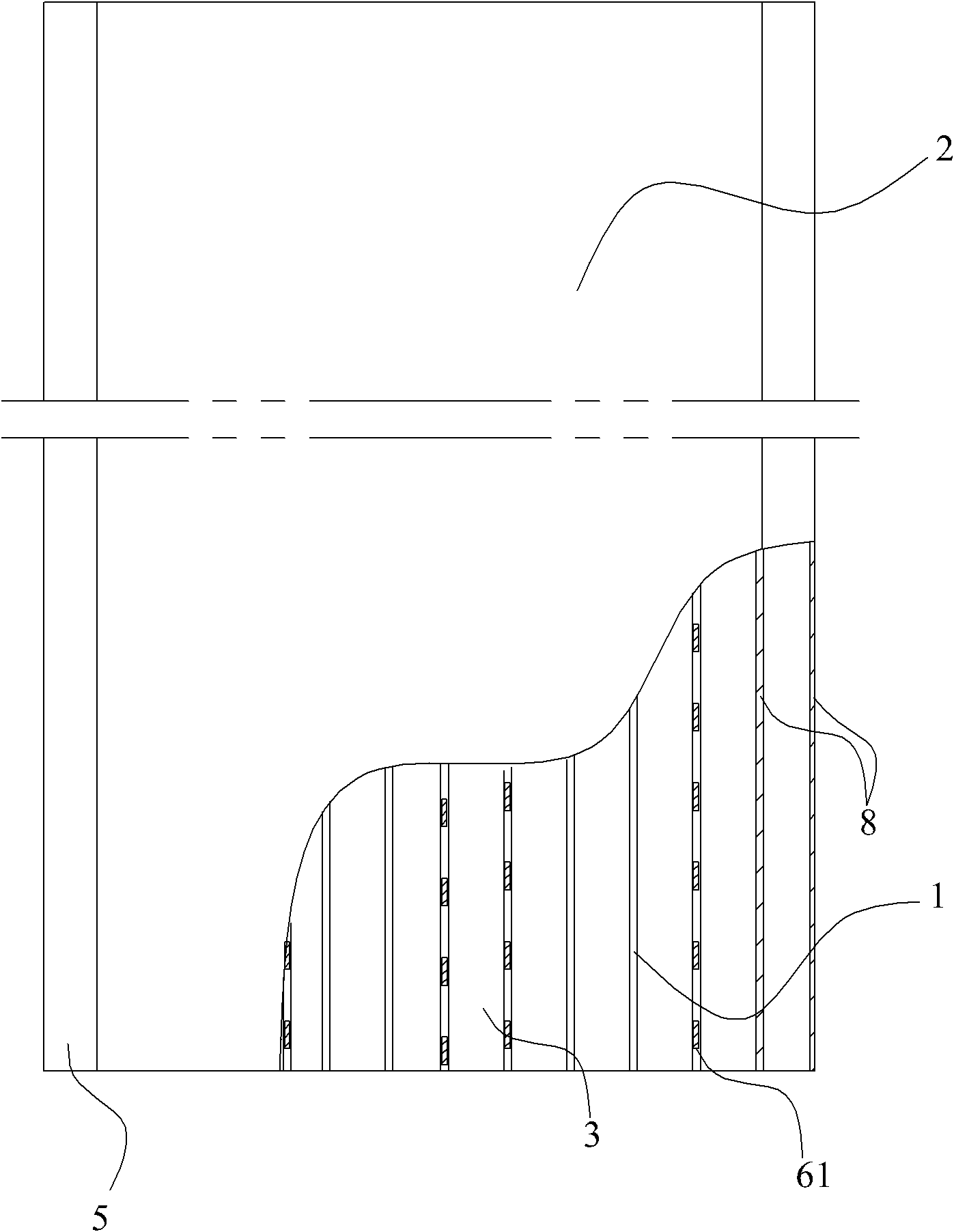

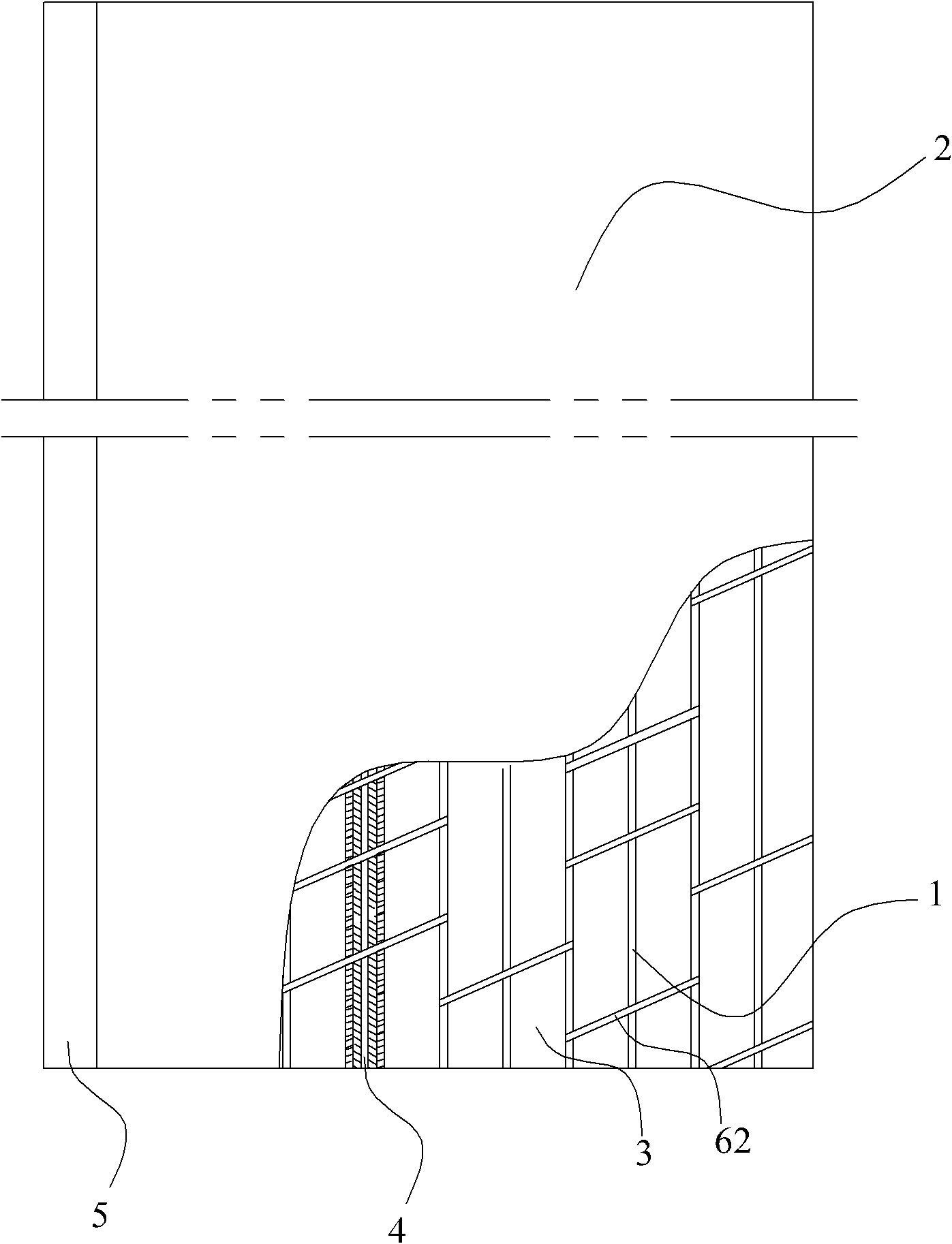

[0037] like figure 1 As shown, in Embodiment 1, a new pasted composite drainage member includes a core plate 1 made of plastic or synthetic resin with a plurality of longitudinal parallel drainage channels 3, and the front and back sides of the core plate are provided with drainage channels 3. The outside of the board is covered with two filter membrane layers 2, and the long edges are bonded and fixed to the top surfaces of the two racks at the side ends of the core plate through adhesive seam strips 8. This method can also be used: one of the filter membrane layers The long edge presses and seals the long edge of another filter membrane layer, or there are two filter membrane layers with a width greater than that of the core plate, and their long edges are pasted and fixed on the left and right sides of the core pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com