Radio-frequency heating carbon fiber graphitization continuous batching production system and method

A technology of radio frequency heating and production system, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of broken wires, hair ends, etc., to avoid broken wires, shorten working time, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

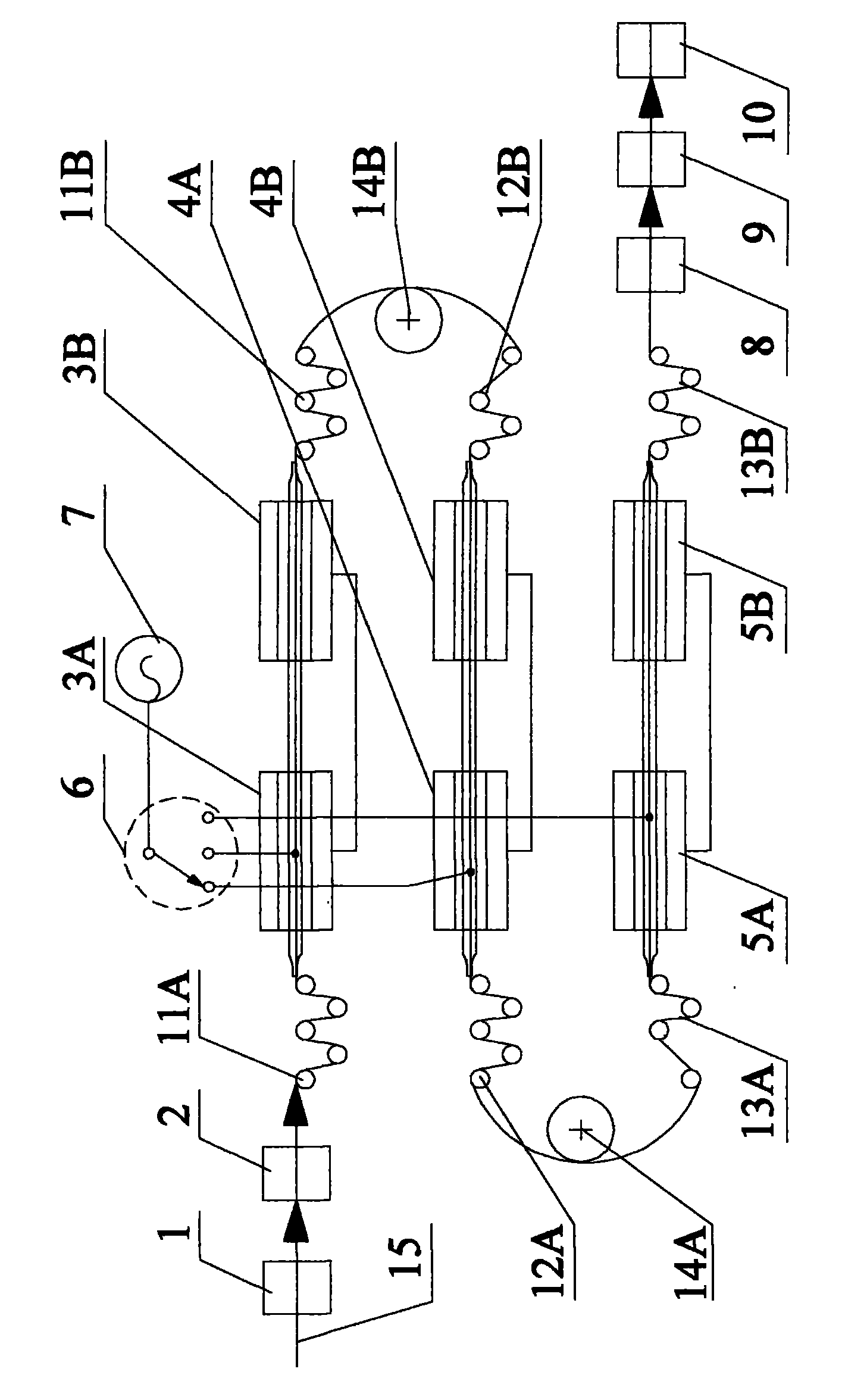

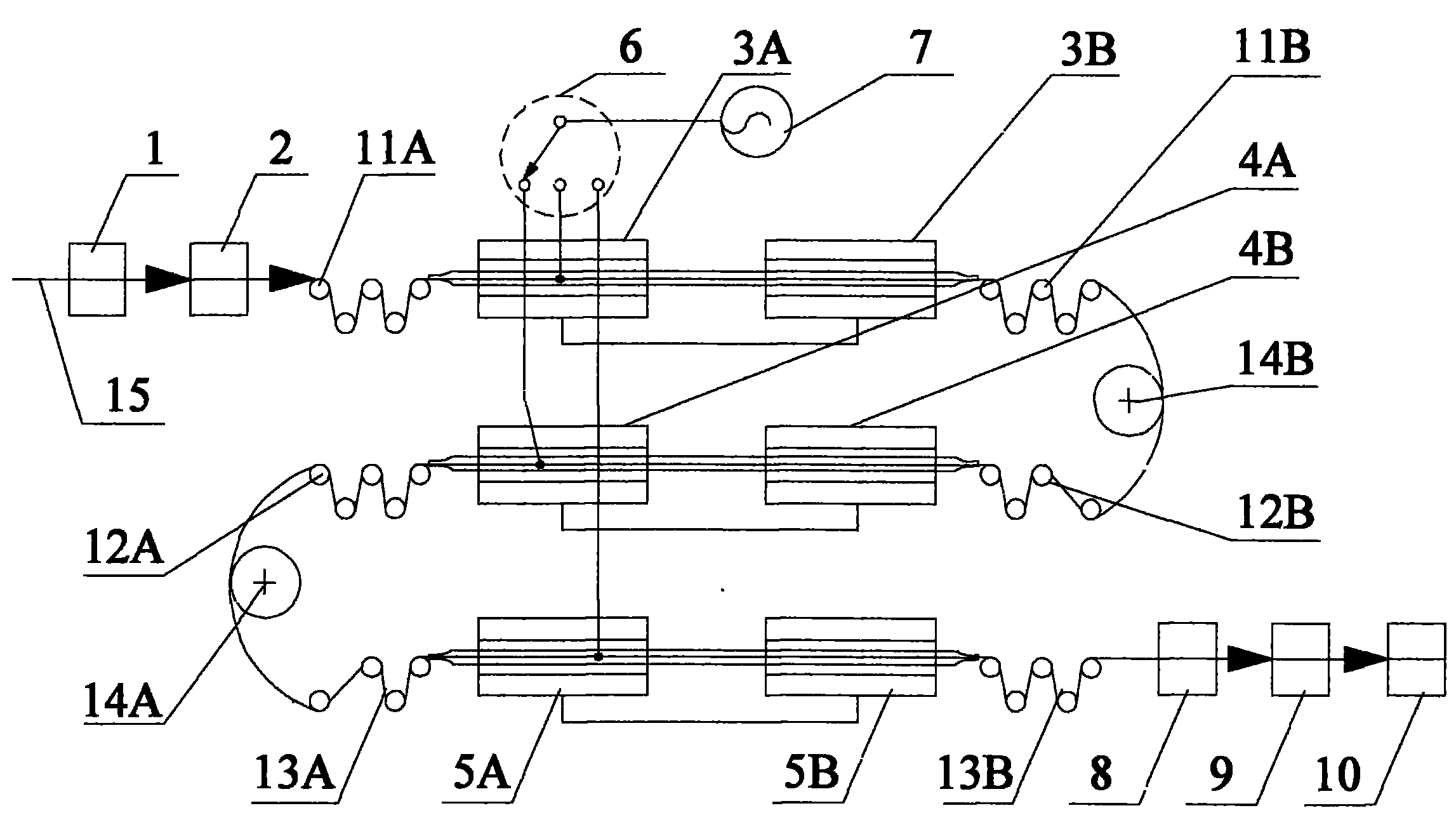

[0012] see figure 1 , radio frequency heating carbon fiber graphitization continuous batch production system, the above system includes a radio frequency heater composed of coaxial conjugated resonant coupling cavity, a high frequency generator 7, a quartz tube thermal reactor arranged in the coupling cavity, The receiving and unwinding mechanisms 1 and 10, the degumming furnace 2, the sizing mechanism 8, the drying furnace 9, and the ambient atmosphere maintenance system and cooling system matched with the heater and the quartz tube thermal reactor are arranged in sequence at both ends of the radio frequency heater. In the continuous batch production system, at least two independent radio frequency heaters 3A-3B, 4A-4B, 5A-5B are combined in series, and the processed carbon fiber 15 passes through each independent radio frequency heater 3A-3B, 4A in sequence - 4B, 5A-5B, a multi-position power output switch 6 is set between the radio frequency heater group and the high freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com