Preparation and application of low-density full diphenyl-methane-diisocyanate (MDI)-base high-resilience polyurethane foam

A technology of foam plastics and polyurethane, which is applied in the application field of car seat materials, and can solve problems such as easy waste, large compression permanent deformation, and narrow process range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Preparation of component A:

[0097] According to the formula given in Table 1, stir evenly at normal temperature and get final product.

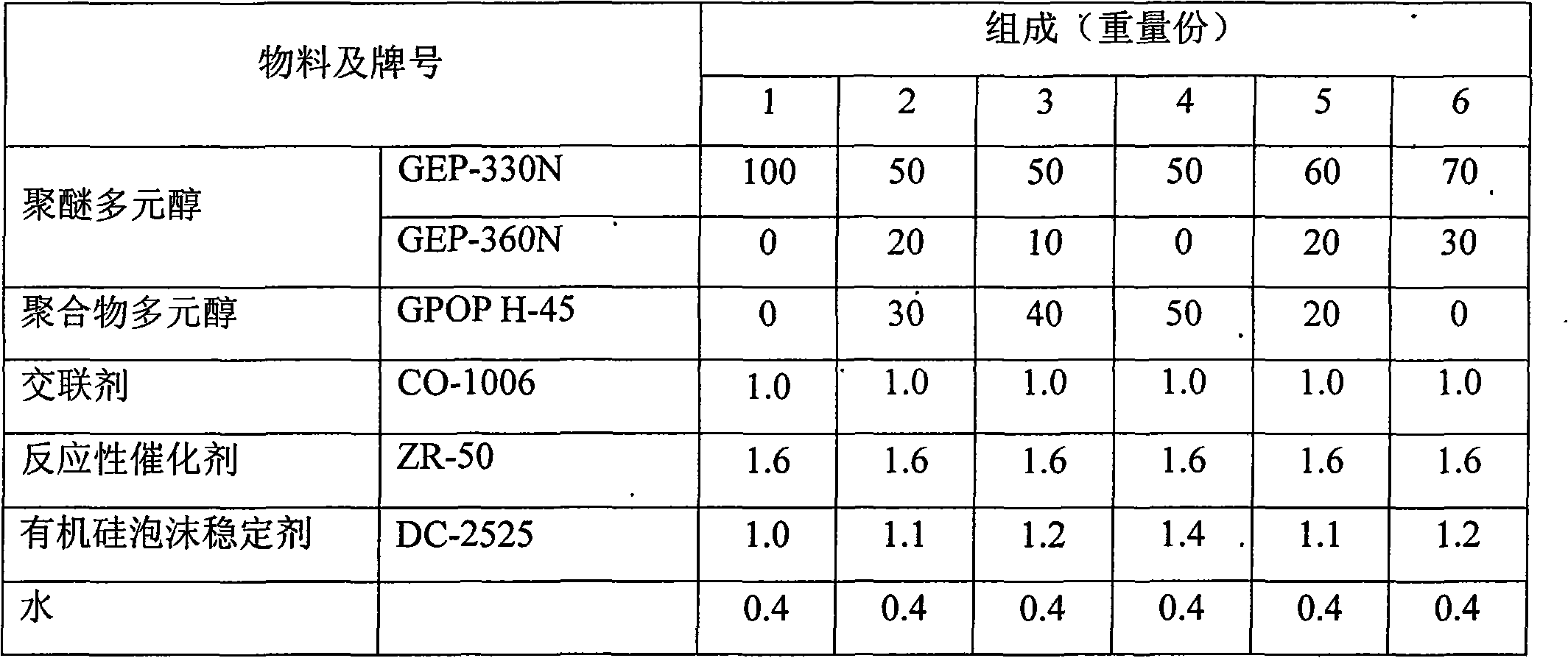

[0098] Table 1. Composition of Part A

[0099]

Embodiment 2

[0101] Preparation of Component B:

[0102] (1) Synthesis of carbamate modified MDI prepolymer (I):

[0103] (1) Dehydration of polyols: first put a sufficient amount of polyether polyol GEP-360N into a reaction kettle with a stirrer and a vacuum system, heat to 120°C under stirring, then vacuumize to -0.09MPa, dehydrate at 120 minutes, then cooled to room temperature.

[0104] (2) Preparation of carbamate-modified MDI prepolymer (I): 78 parts of 4,4'-MDI and 22 parts of 2,4-MDI / 4,4MDI mixture Put it into another reaction kettle, under the protection of nitrogen, stir and heat up to 60°C, then add 10 parts of the above-mentioned dehydrated GEP-360N polyether polyol in batches, and the feeding speed is based on the fact that the exotherm of the reaction mixture does not exceed 80°C The upper limit, after adding the polyol, continue to react for 4 hours, cool to room temperature, pack and store in a sealed container. Tested according to GB 12009.4-89, the NCO content is: 3...

Embodiment 3

[0111] Preparation of low-density all-MDI-based high-resilience polyurethane foam:

[0112] The process conditions for preparation are: component A: component B is equal to 100:65; the mold temperature is 50°C; the material temperature is 22°C and the injection pressure is 11Mpa. Mold size is 40*40*10cm 3 .

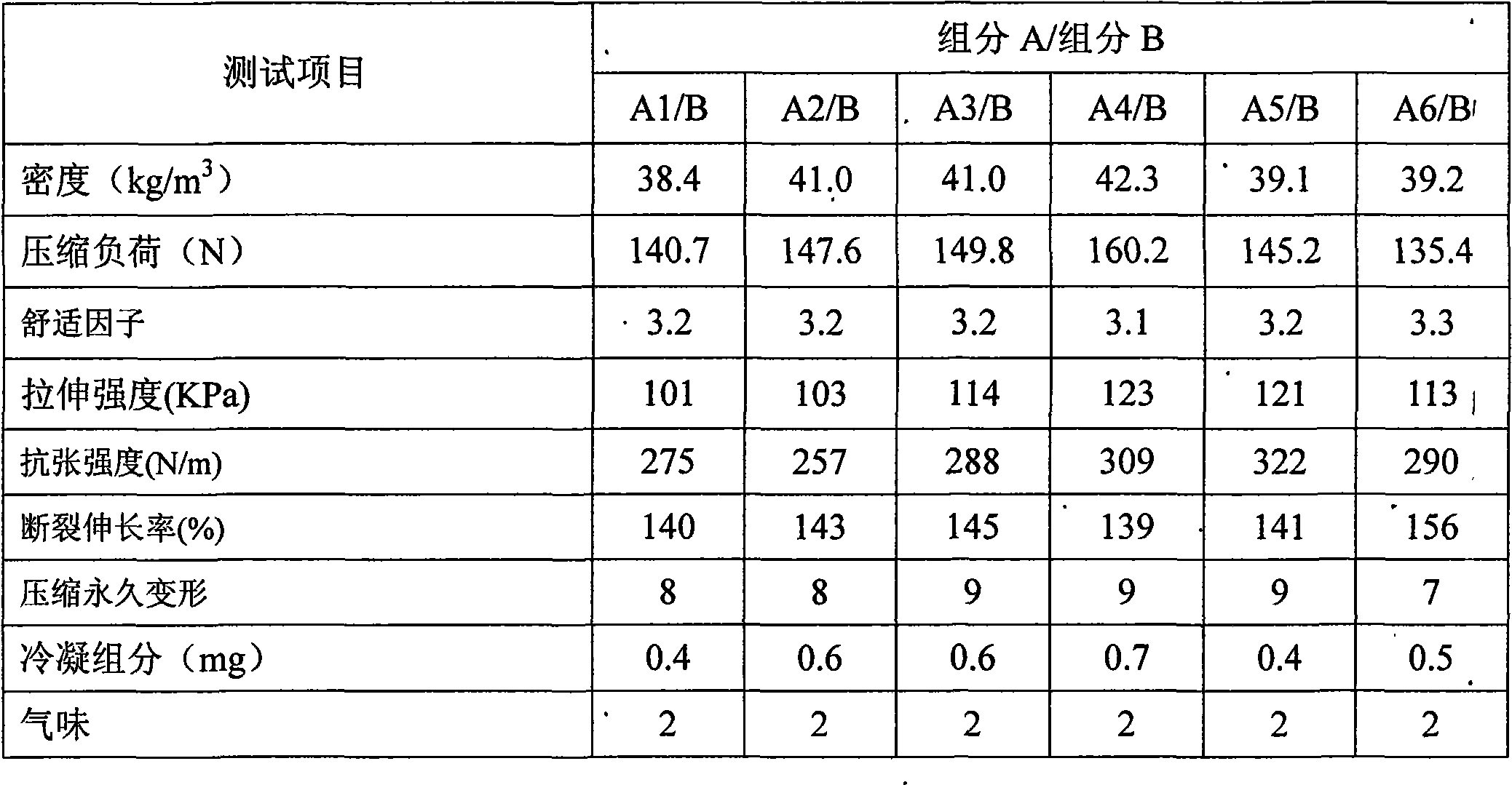

[0113] The technical properties of the high-resilience polyurethane foam formed by the corresponding compositions of component A of Example 1 and component B of Example 2 are listed in Table 2. A1 / B represents the high-resilience polyurethane foam formed by the casting foaming process of the formulation 1 of component A in Table 1 and component B in Example 2. Similarly, A2 / B represents the formula 2 of component A in Table 1 and the high-resilience polyurethane foam formed by component B in Example 2 through a pouring foaming process; A3 / B represents the formula of component A in Table 1 3 and the high-resilience polyurethane foam formed by pouring and foaming process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com