Wingtip cover mirror face part drawing processing method

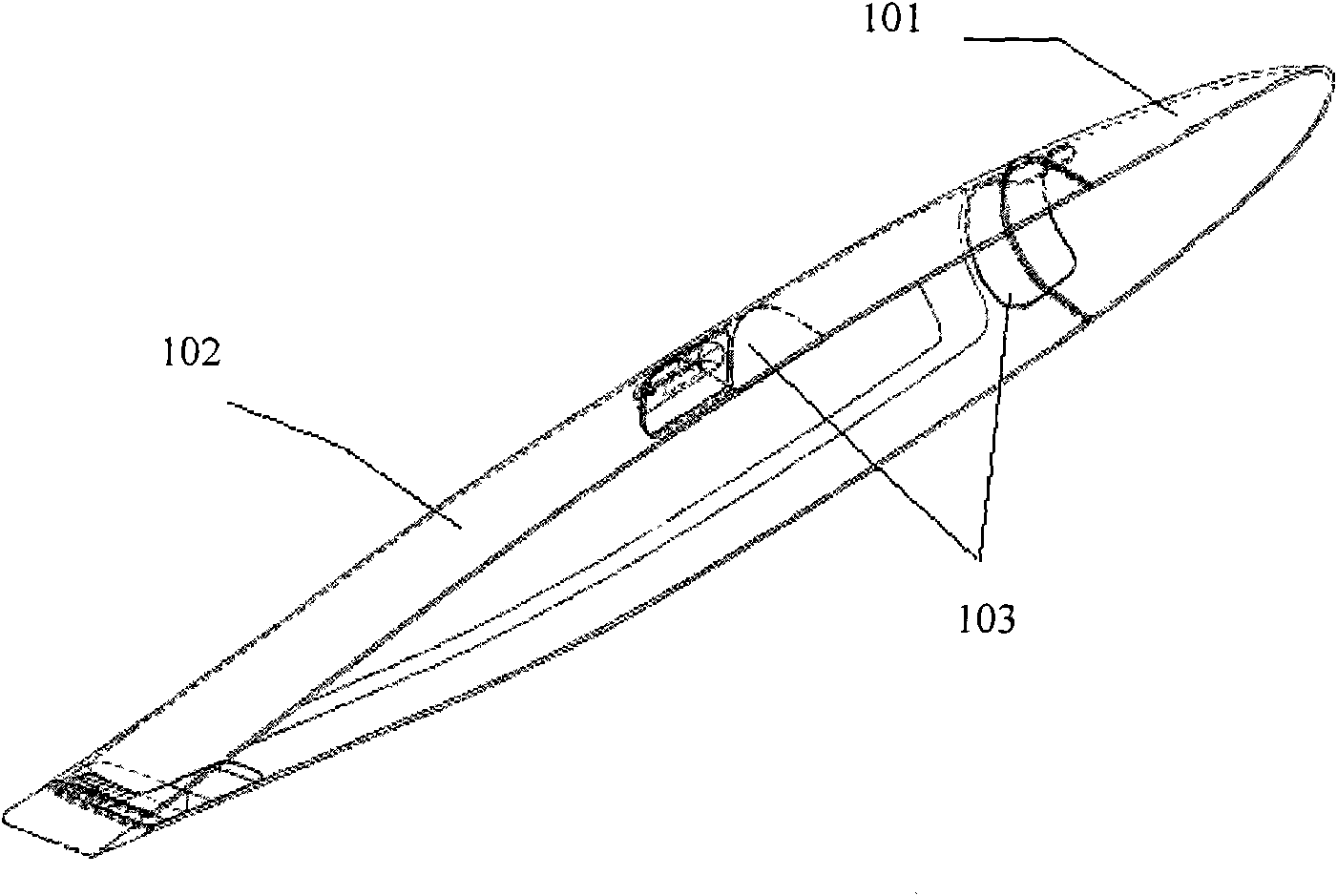

A processing method and a technology of parts, which are applied in the field of aircraft wingtip cover mirror parts using deep drawing dies and deep drawing processing, can solve the problems of difficult to guarantee the mirror surface, high scrap rate of parts, easy to scratch, etc., so as to ensure product quality , shape accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below through specific embodiments.

[0036] The method of the present invention is used for deep-drawing manufacturing of mirror material parts, that is, deep-drawing processing of mechanically polished skin materials. The so-called machine-polished skin material exhibits a high-quality reflective appearance, with uniform color grade, finish and reflectivity, for use on unpainted aircraft.

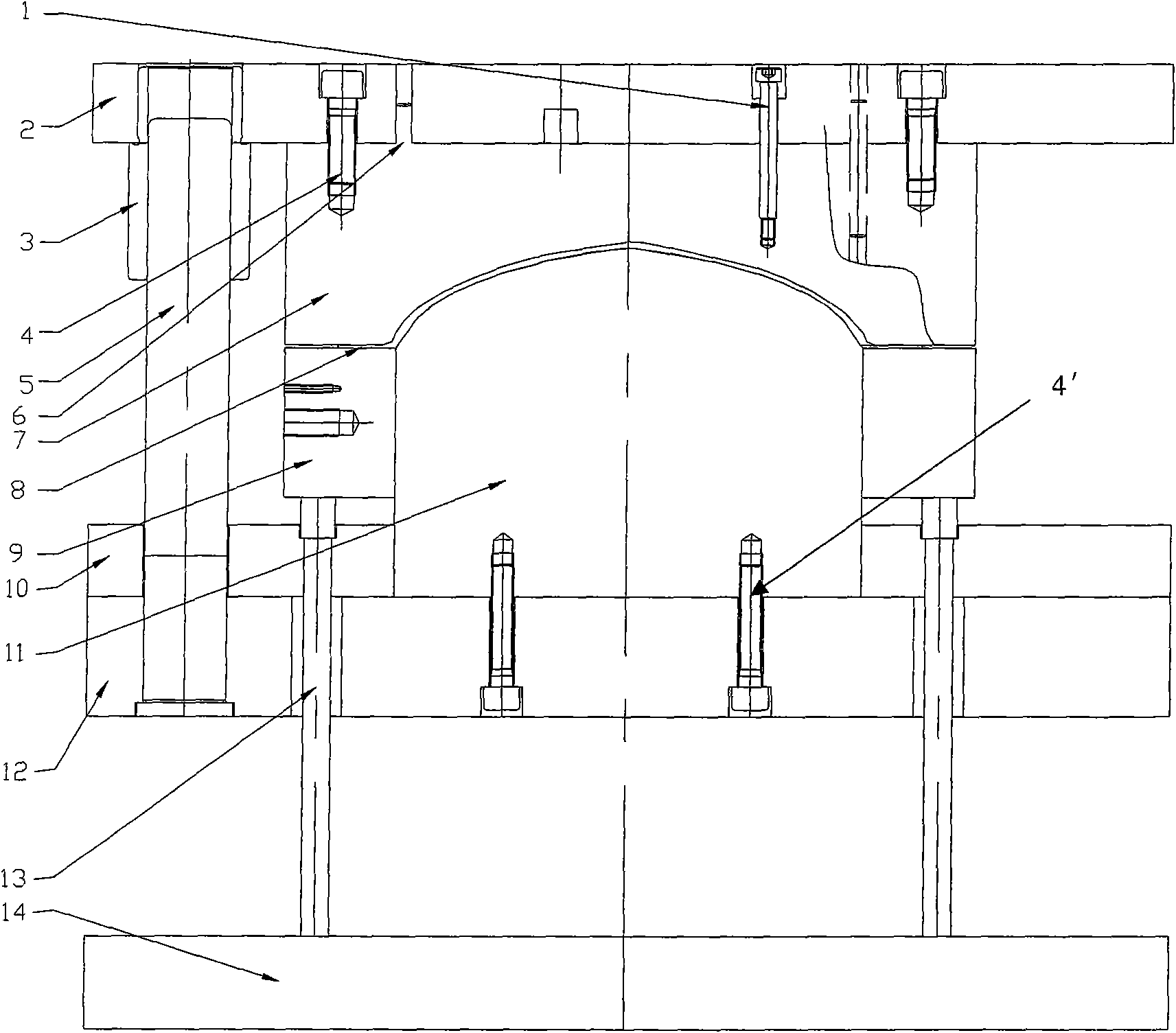

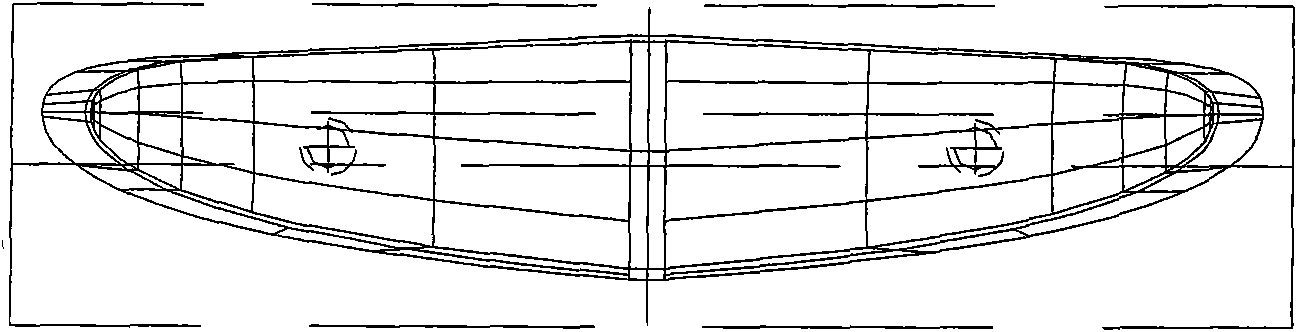

[0037] The basic structure of the drawing die used in the present invention is composed of two parts: a concave die and a punch; the structural form of the drawing die designed according to the structural characteristics of open left and right sides of the parts is one pressing two parts.

[0038] Such as figure 2 Shown is a schematic structural view of a specific example of a drawing die used in the present invention. The drawing die comprises: an upper formwork (2) and a lower formwork (12), the upper formwork (2) and the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com