Thermally stable oil-in-water microemulsion

An oil-in-water and microemulsion technology, which is applied in skin care preparations, cosmetics, cosmetics, etc., can solve problems such as cumbersome, unfavorable practical preparations, and complex formulas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

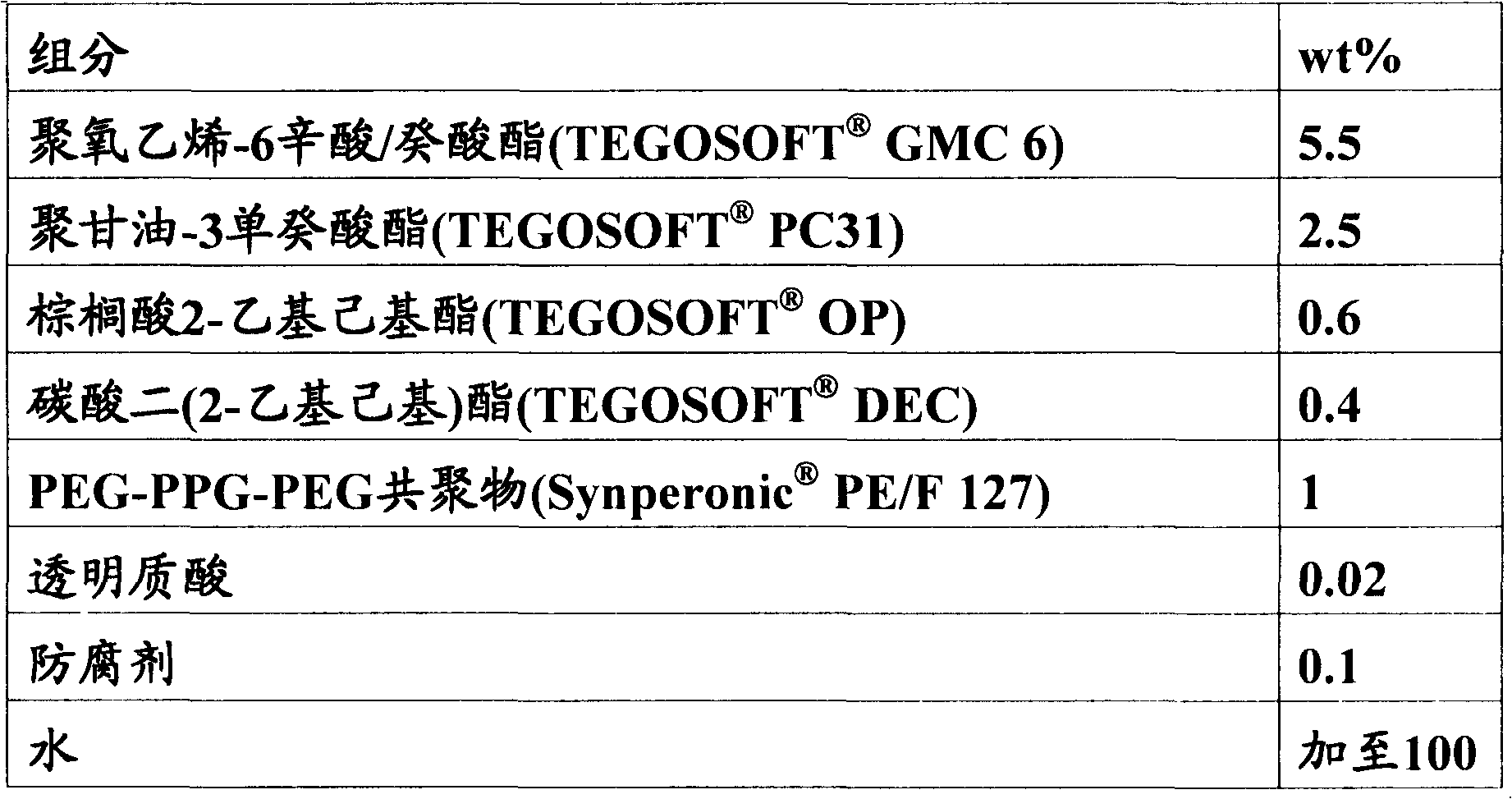

[0074] The formulation of Example 1 is shown in Table 1 below.

[0075] Table 1

[0076]

[0077] The components in the above Table 1 were stirred and mixed uniformly at 40°C, and then cooled to room temperature to obtain Product 1, which was completely transparent in appearance. The average particle diameter of product 1 measured by DELSA NANOS particle size distribution instrument of BECKMAN COULTER company is about 40nm, forming a microemulsion.

Embodiment 2

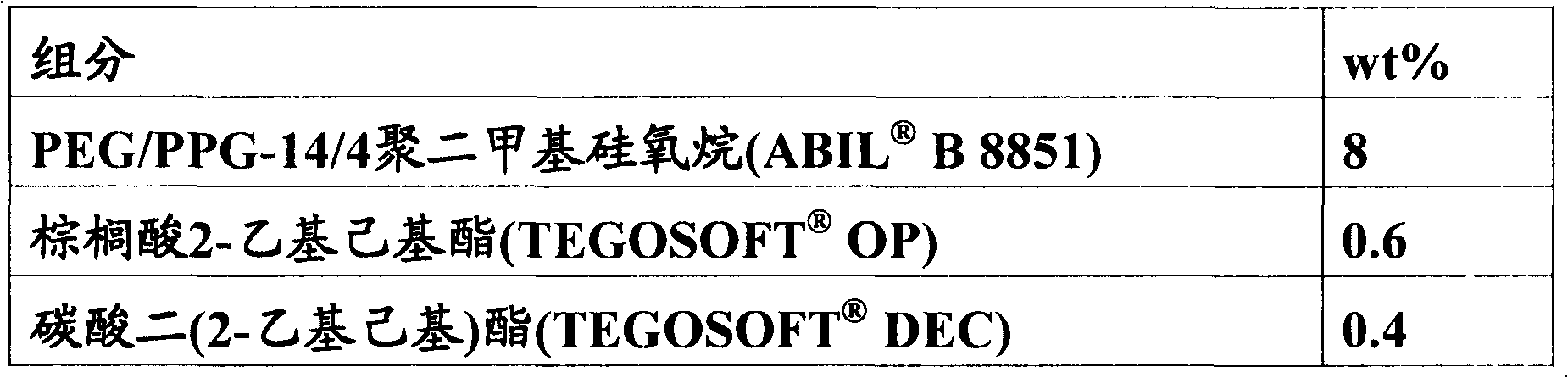

[0079] The formulation of Example 2 is shown in Table 2 below.

[0080] Table 2

[0081]

[0082]

[0083] The components in the above Table 2 were stirred and mixed uniformly at 40°C, and then cooled to room temperature to obtain product 2, which was completely transparent in appearance. The average particle diameter of product 2 measured by DELSA NANOS particle size distribution instrument of BECKMAN COULTER Company is about 89nm, forming a microemulsion.

Embodiment 3

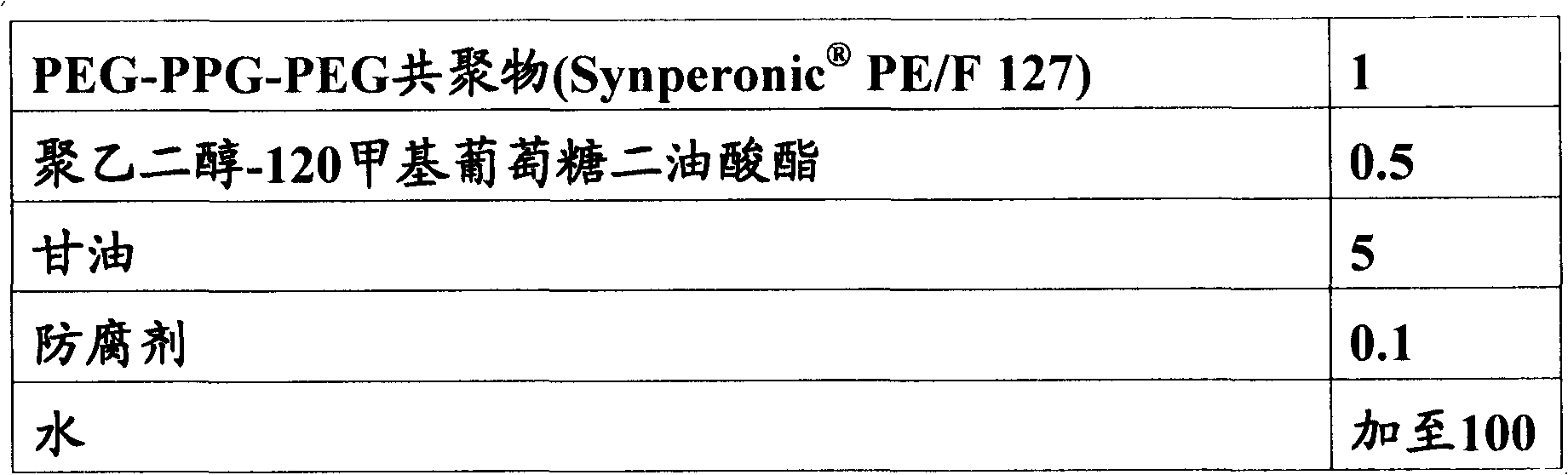

[0085] The formulation of Example 3 is shown in Table 3 below.

[0086] table 3

[0087]

[0088] The components in the above Table 3 were stirred and mixed uniformly at 40°C, and then cooled to room temperature to obtain product 3, which was completely transparent in appearance. The average particle diameter of the product 3 measured by DELSA NANOS particle size distribution instrument of BECKMAN COULTER Company is about 80nm, forming a microemulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com