PFC (power factor correction) control method with high input power factor and control circuit thereof

A technology of power factor and control method, which is applied in the field of high input power factor PFC control method and its control circuit, can solve the problems of small output voltage ripple, low precision, complicated method, etc., and reduce the output voltage ripple , easy to achieve, simple control circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

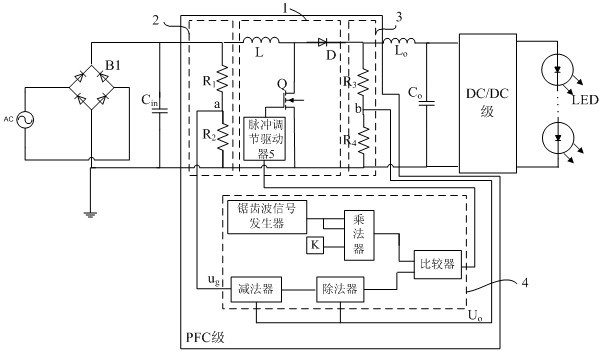

[0034] The following is an LED drive circuit with variable duty cycle control combined with PFC stage, as attached figure 1 , the specific implementation of the technical solution of the present invention will be further described in detail, but the implementation and protection scope of the present invention are not limited thereto.

[0035] The basic structure of the LED drive circuit is composed of input power supply, uncontrolled rectifier bridge, input filter, PFC stage, output filter, DC / DC stage, and LED lamp load.

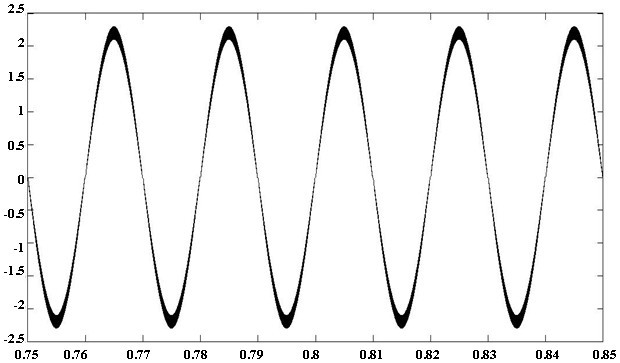

[0036] Let the input voltage be , then the output voltage of the uncontrolled rectifier bridge is .

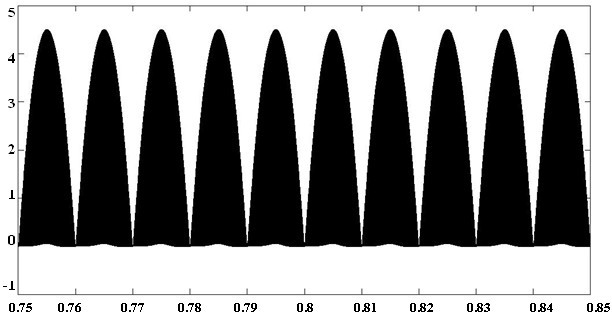

[0037] During one switching cycle, the peak value of the inductor current is:

[0038] (5)

[0039] in Indicates the switch conduction duty cycle.

[0040] From the equalization of volt-seconds across the inductor during each switching cycle:

[0041] (6)

[0042] in Indicates the duty cycle of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com