Structured light stripe central point reliability evaluation method

A light bar center and evaluation method technology, applied in the direction of optical devices, special data processing applications, measurement devices, etc., can solve problems such as low precision, high algorithm complexity, and noise sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0117] Use the above-mentioned evaluation method to evaluate the reliability of the light strip image:

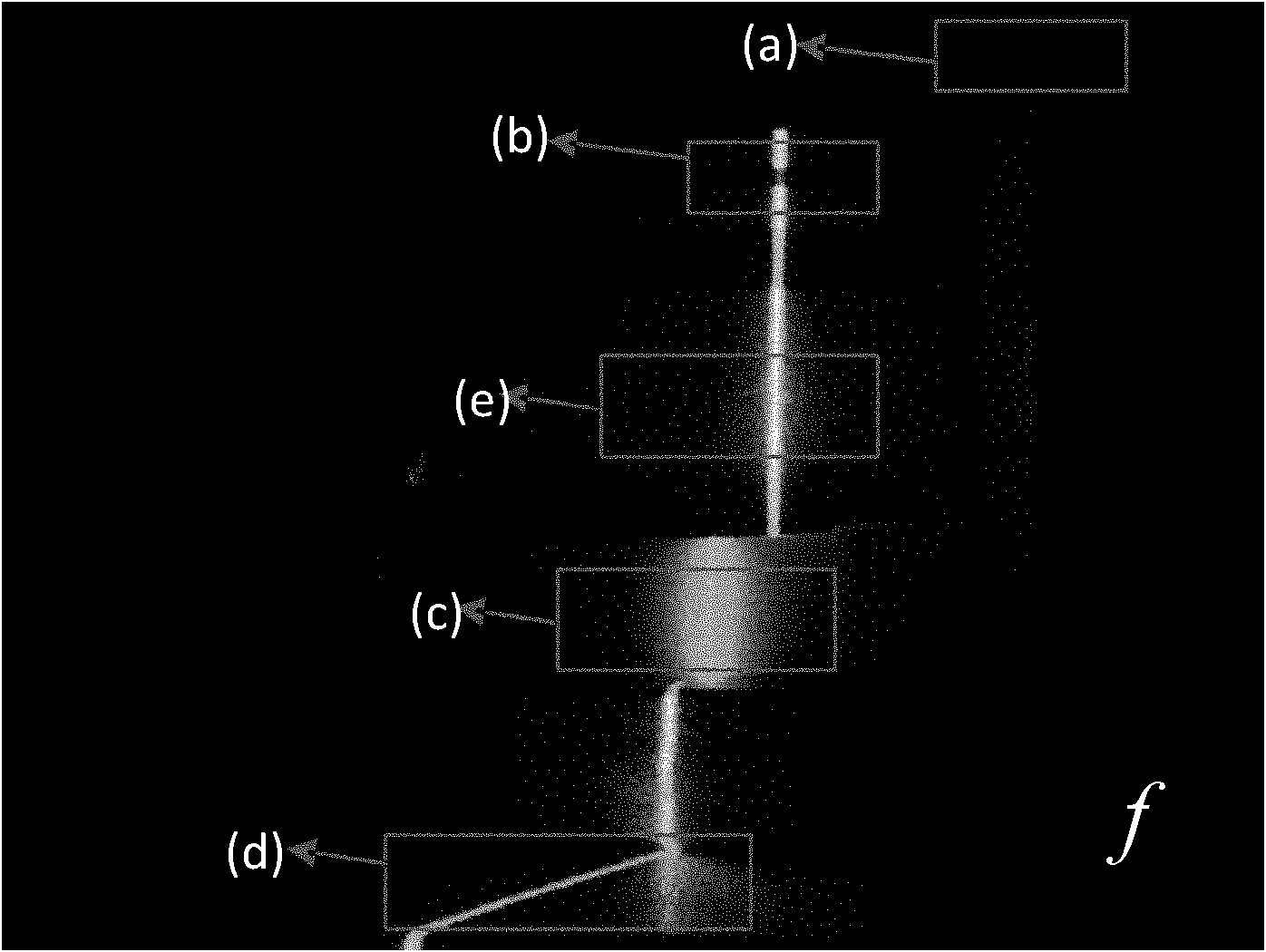

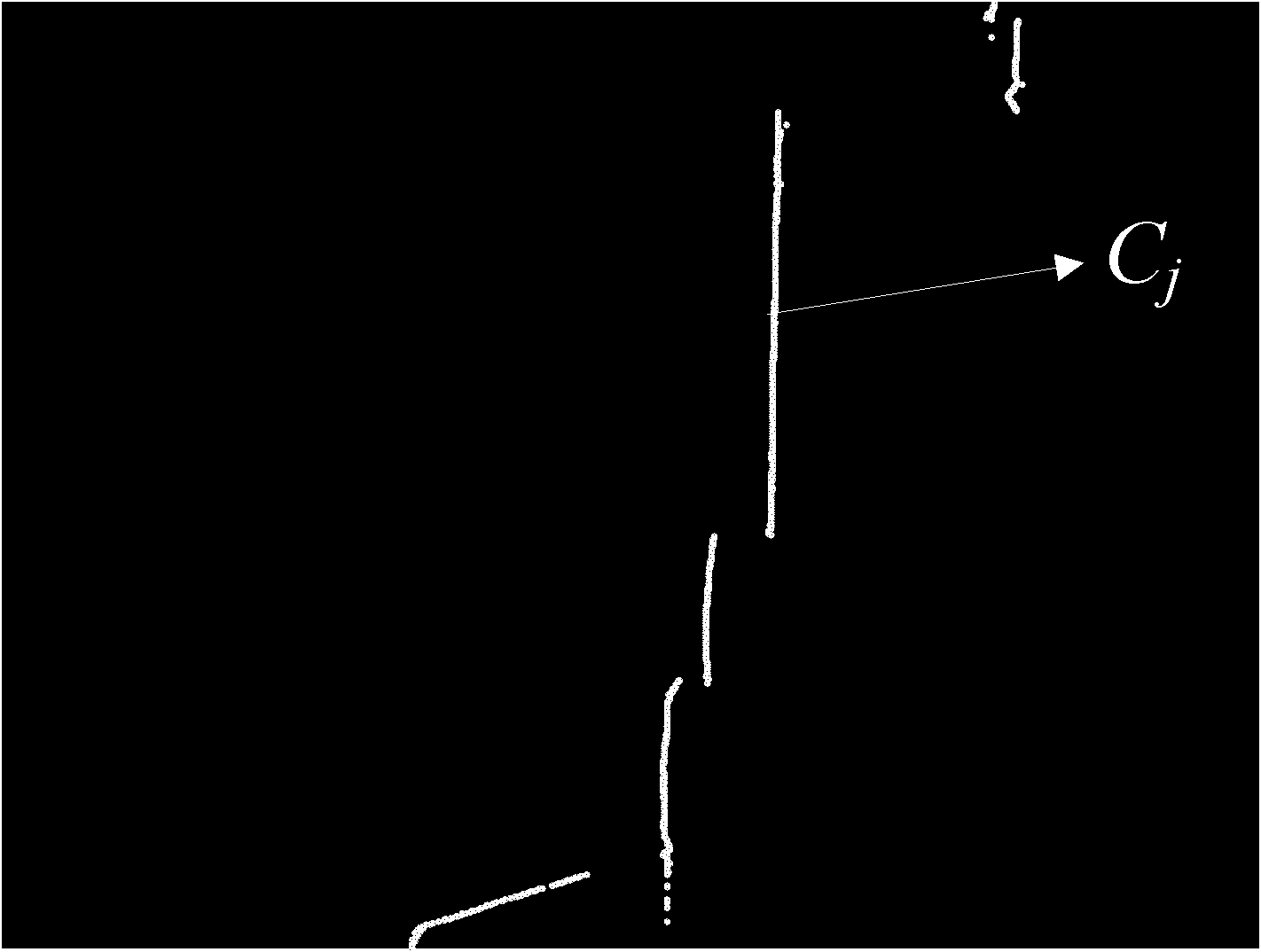

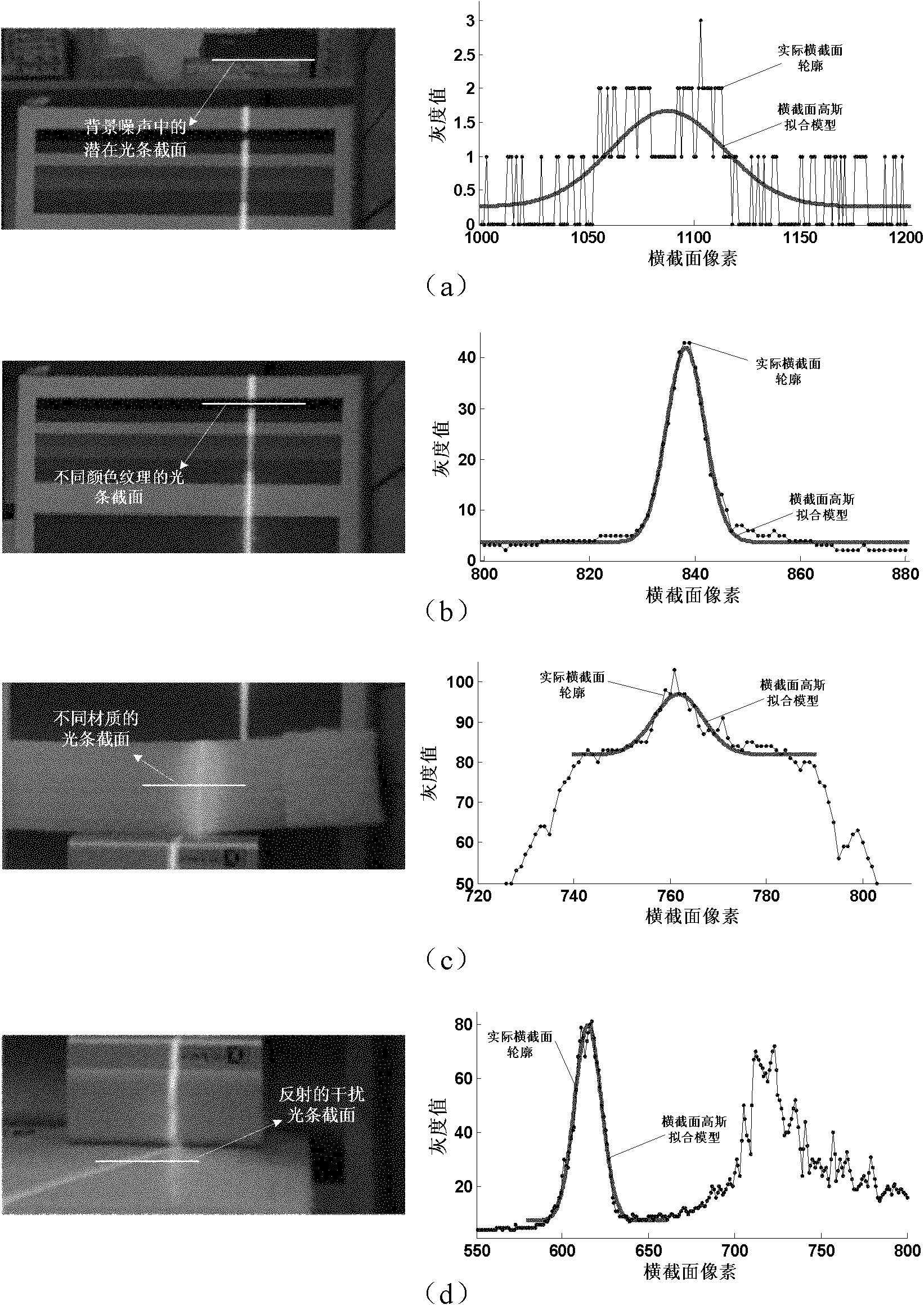

[0118] Such as Figure 8 shown in figure 1 As an example, the evaluation method of the present invention, and the original gray value of the center point and the second-order gradient value of the Hessian matrix are used as reliability evaluation criteria to evaluate figure 2 The center point of the light bar obtained above. in Figure 8 (a), (b), (c), (d) correspond to figure 1 In (a), (b), (c), (d) four cases, Figure 8 (e) is a Gaussian curve with a better shape, which is the most reliable. It is used as a reference for other situations. The qualitative analysis of the comparison results is shown in Table 1:

[0119] Table 1 Qualitative analysis results of various situations

[0120]

[0121] Note: ○ indicates that the evaluation results are more accurate and in line with the actual situation, △ indicates the next best, and × indicates the worst.

[0122] For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com