Soft measurement method of reducing power quality index in process of calcinating lithopone

An achromatic, zinc-barium-white technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as increasing model complexity and increasing data noise sensitivity, reducing input dimensions, The effect of speeding up training and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

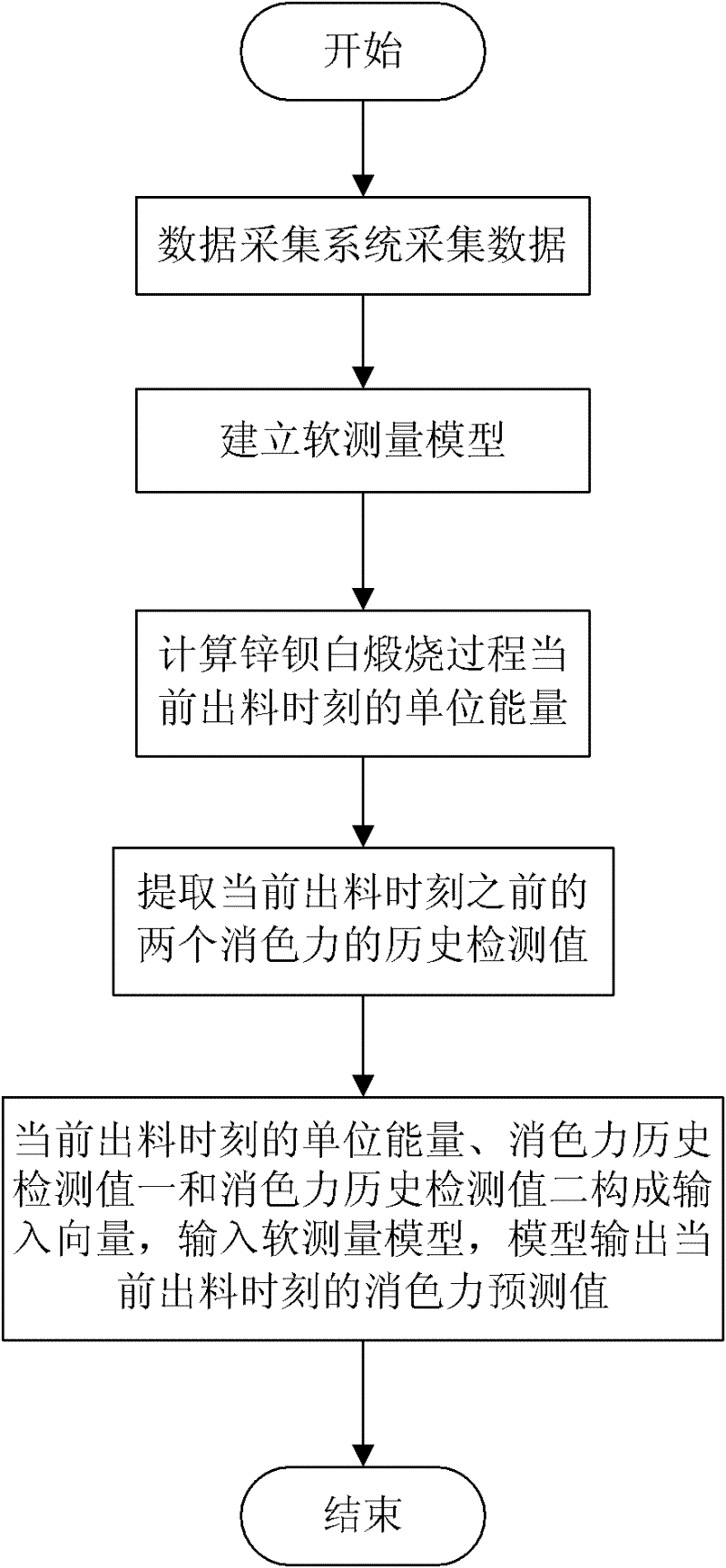

[0055] like figure 1 As shown, the soft measurement method of the color reduction power of the lithopone calcining process comprises the following steps:

[0056] (1) collect the calcining temperature data in the lithopone calcining process through the thermocouple in the data acquisition system, collect the calcining rotational speed data in the lithopone calcining process through the speed sensor in the data acquisition system, and The calcining temperature data and calcining speed data are saved to the data storage system in the control computer through the transmitter and the programmable logic controller; the historical detection values of the decolorization power are collected manually, and the history of the decolorization power is input into the data storage system detection value;

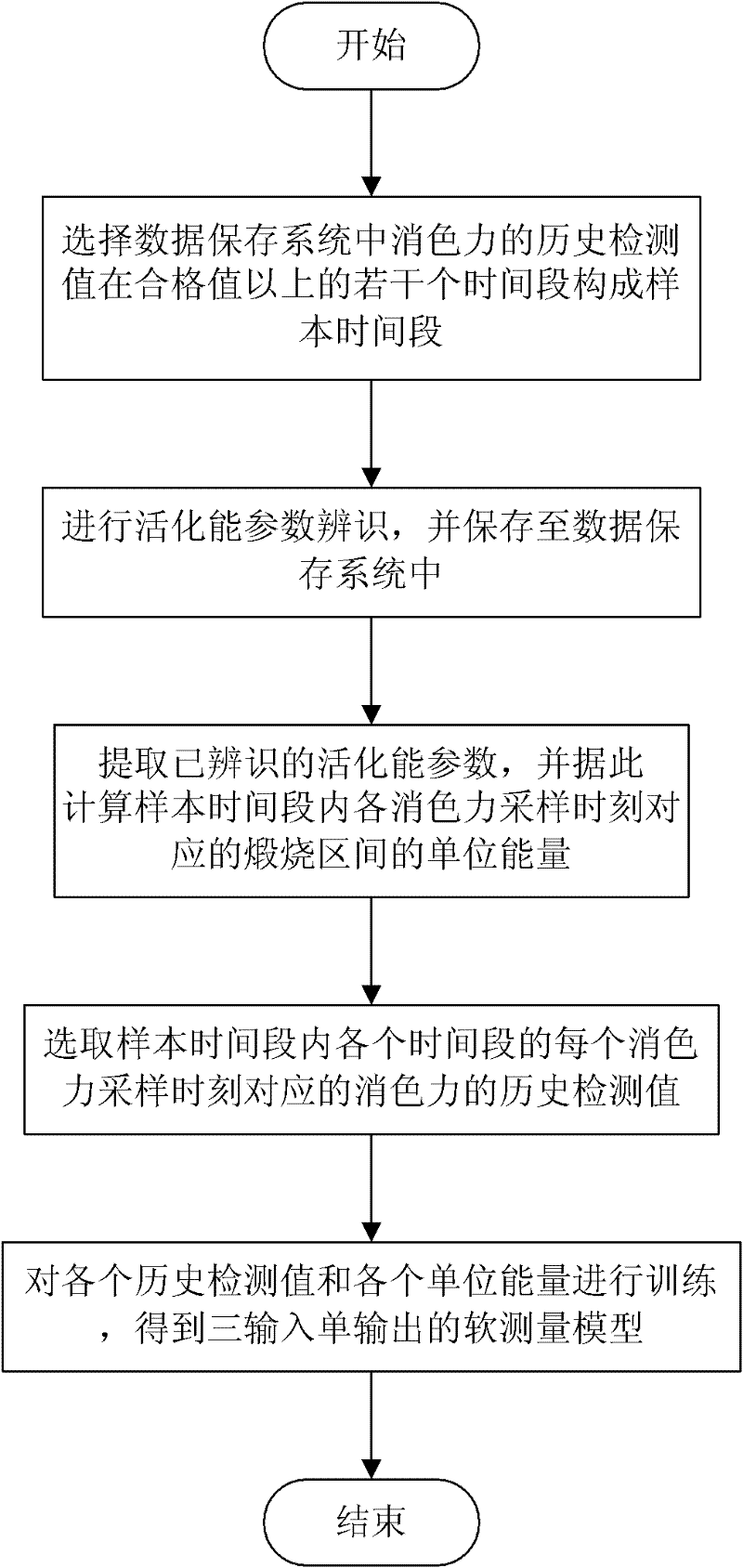

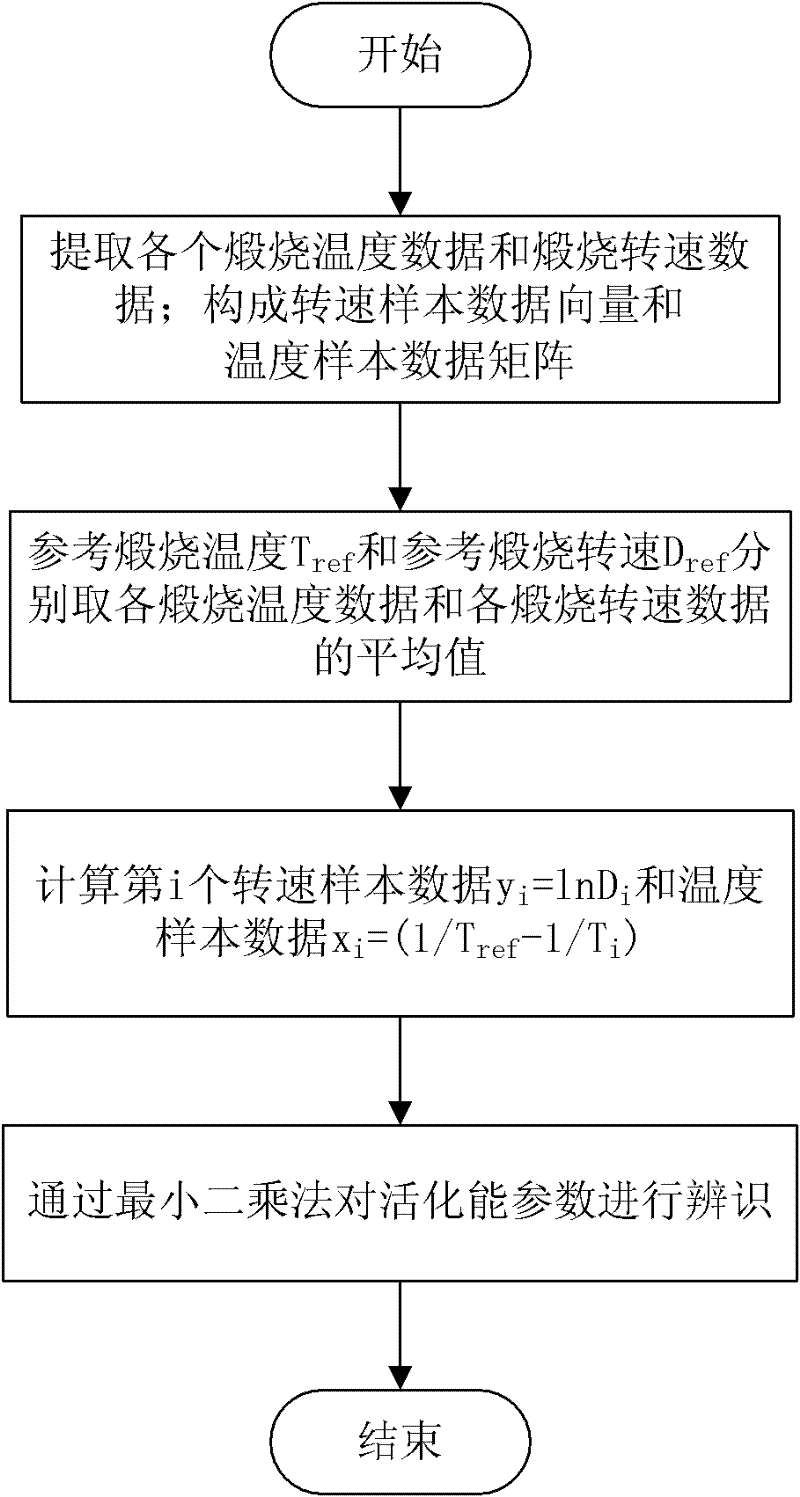

[0057] (2) Select the sample time period, through the unit energy of the calcination interval corresponding to each decolorizing power sampling moment in the sample time period and the ...

Embodiment 2

[0095] The features of this embodiment are the same as those of Embodiment 1 except for the following features: the sampling period for the manual collection of the historical detection value of the achromatic power is 2 hours, and the calcination temperature data and the calcination rotational speed data in the calcination process are The acquisition period was 5 minutes.

[0096] In the step (2-1), the sample time period is a sample time period composed of ten time periods in which the historical detection value of achromatic power in the data storage system is above the qualified value;

[0097] In the step (2-2-3), m is the total number of calcination temperature data or calcination rotational speed data, and m is taken as 200.

Embodiment 3

[0099] The features of this embodiment are the same as those of Embodiment 1 except for the following features: the sampling period for the manual collection of the historical detection value of achromatic power is 1.5 hours, the calcination temperature data and the calcination rotational speed data in the calcination process The acquisition period was 3 minutes.

[0100] In the step (2-1), the sample time period is a sample time period composed of twenty time periods in which the historical detection value of achromatic power in the data storage system is above the qualified value;

[0101] In the step (2-2-3), m is the total number of calcination temperature data or calcination rotational speed data, and m is taken as 160.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com