Large tonnage pile static loading test ballasting platform counter-force device and mounting method thereof

A reaction device and static load test technology, which is applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of large consumption of counterweight materials, difficulty in moving, and difficulty in meeting the strength requirements, so as to reduce loading and Transportation cost, installation method is simple and safe, and the effect of solving strength and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

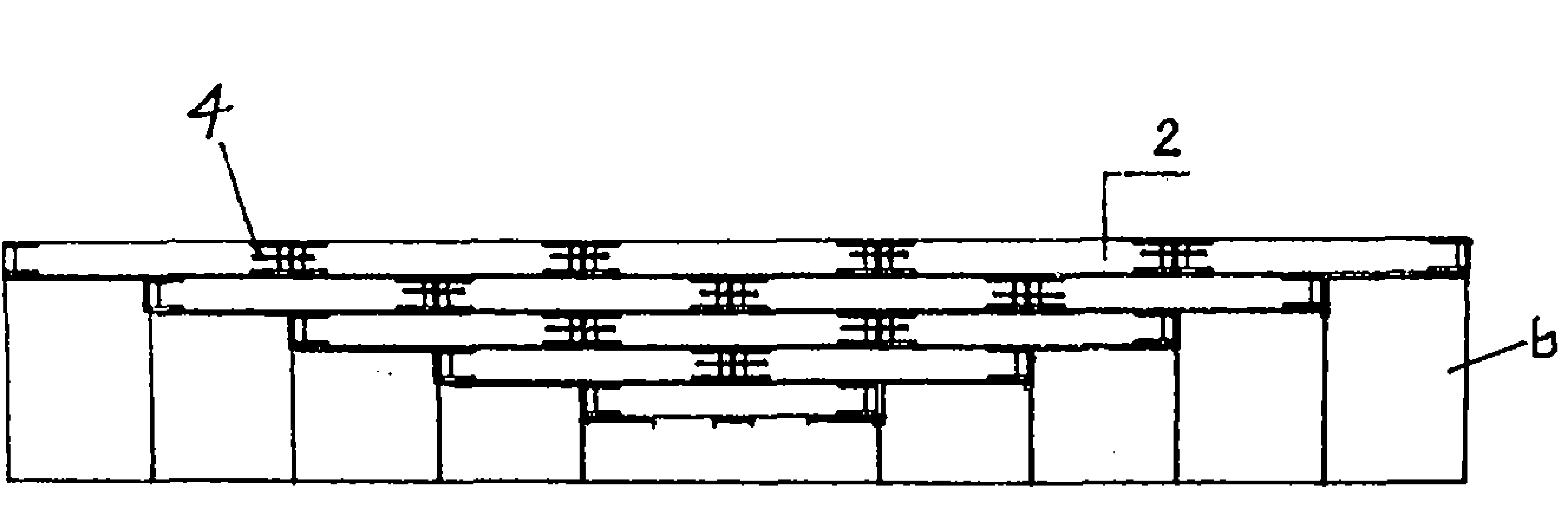

[0029] A construction project needs to carry out a 5000-ton pile foundation static load test, and it is required to use a steel-concrete load-bearing platform to form a counterforce device for the ballast platform.

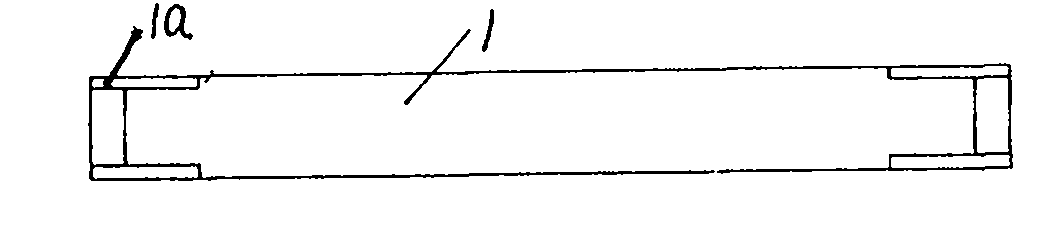

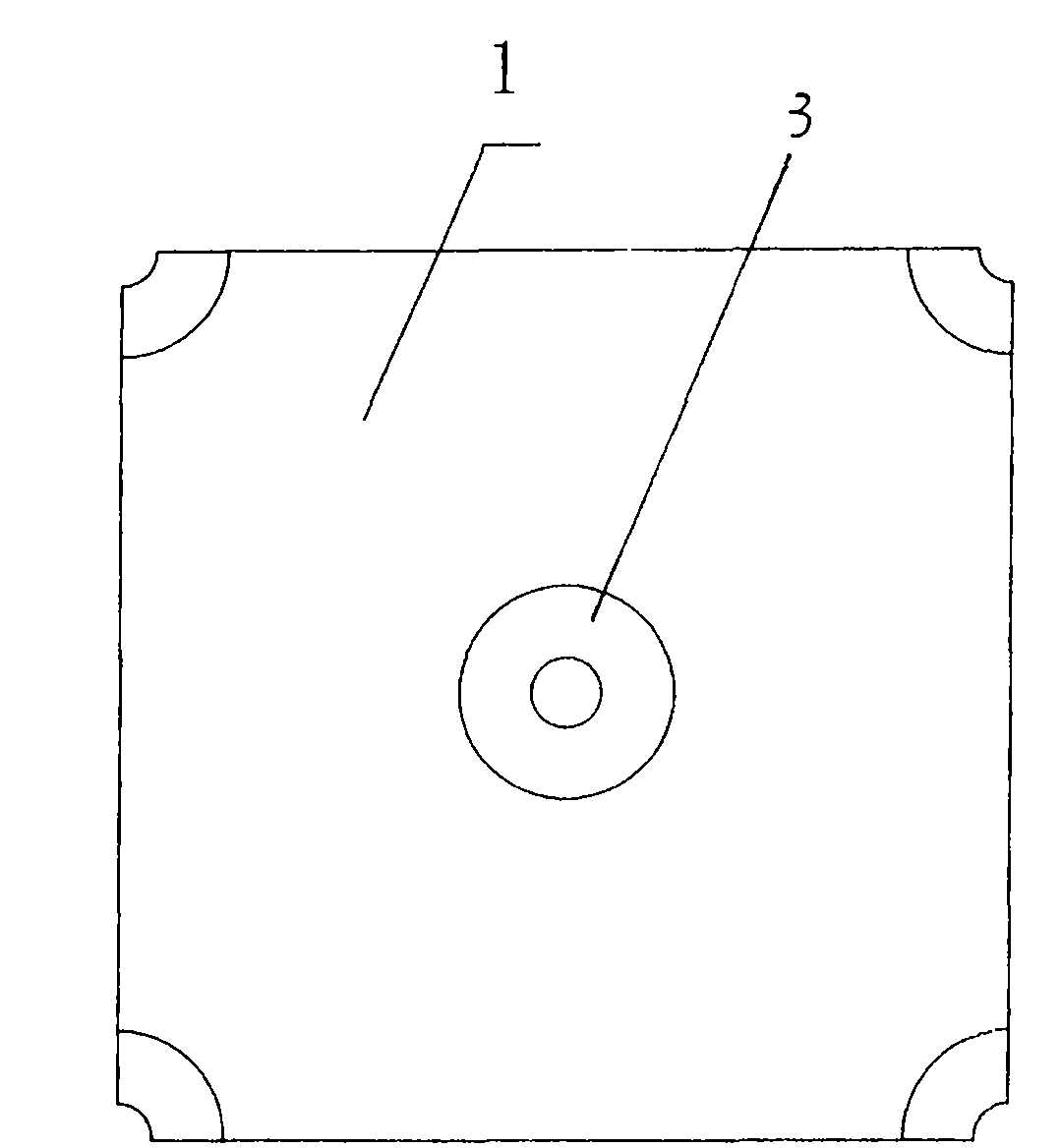

[0030] The steel-concrete load-bearing platform is manufactured using the existing technology, and the geometric dimensions (length×width×thickness) of the steel-concrete load-bearing platform are 4×4×0.5(m 3 ), the frame of the steel-concrete load-bearing platform and the load-bearing bars radiating outward from the central countersunk keyhole are made of industrial steel. After welding and forming, reinforced steel bars are added, and high-strength commercial concrete is poured and cured.

[0031] Using existing technology to make counterweight box 7 and static load-bearing support 6: according to the geometric dimensions of the steel-concrete load-bearing platform, the geometric dimensions (length × width × height) of the supporting counterweight box are also se...

Embodiment 2

[0040] A construction project needs to carry out a 7000-ton pile foundation static load test, and it is required to use a steel-concrete load-bearing platform to form a counterforce device for the ballast platform.

[0041] The fabrication of the device is the same as in Example 1.

[0042] The installation method is as follows:

[0043] (1) Foundation treatment of static bearing bearings. According to the different conditions of the construction site, it can be treated according to the method or combination of multiple methods stipulated in the industry standard of the People's Republic of China "Technical Regulations for Building Foundation Treatment" (JGJ 79). Design area of reaction device (400m 2 ) is required to reach 25T / m 2 No settlement deformation occurs.

[0044] (2) Static load bearing installation. According to the structure of the load-bearing platform reaction force device, on the treated flat foundation, the load-bearing supports are arranged in order fr...

Embodiment 3

[0050] A construction project needs to carry out a static load test of 10,000 tons of pile foundation, and it is required to use a steel-concrete load-bearing platform to form a pressure platform reaction device or to use a steel-concrete load-bearing platform to form an anchor-pressure joint reaction device.

[0051] The fabrication of the device is the same as in Example 1.

[0052] The installation method is as follows:

[0053] (1) Foundation treatment of static bearing bearings. According to the different conditions of the construction site, according to the method stipulated in the industry standard "Technical Regulations for Building Foundation Treatment" (JGJ 79) of the People's Republic of China and combined with reinforced CFG pile treatment (the CFG pile is considered to be 5m deep), according to the static load test tonnage of the pile foundation ( 10,000 tons) and the design area of the ballast platform reaction force device (400m 2 ), and considering the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com