Piston ring coping machine

A technology of trimming machine and piston ring, which is used in grinding machines, metal processing equipment, grinding/polishing equipment, etc. It can solve the problem of affecting the machining accuracy and product quality of the piston ring, and cannot guarantee the consistent closed gap of the piston ring and the processing speed of the piston ring. Slow and other problems, to avoid workpiece jamming, easy packaging and transportation, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A piston ring trimming machine of the present invention will be described in further detail below in conjunction with the accompanying drawings.

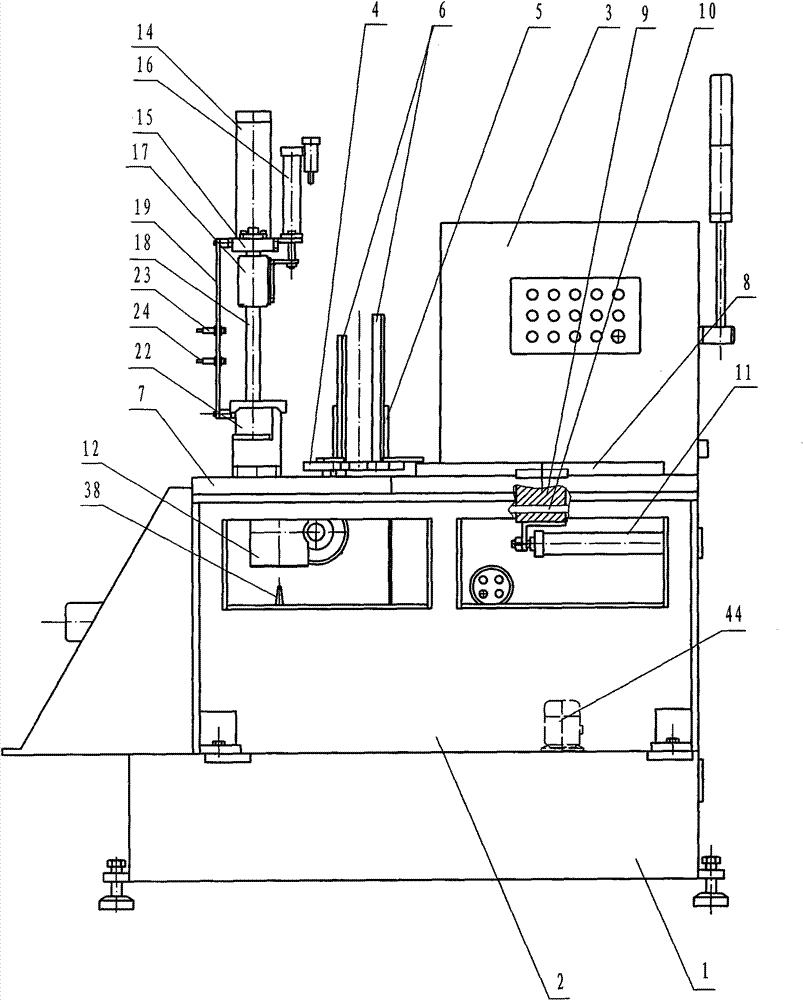

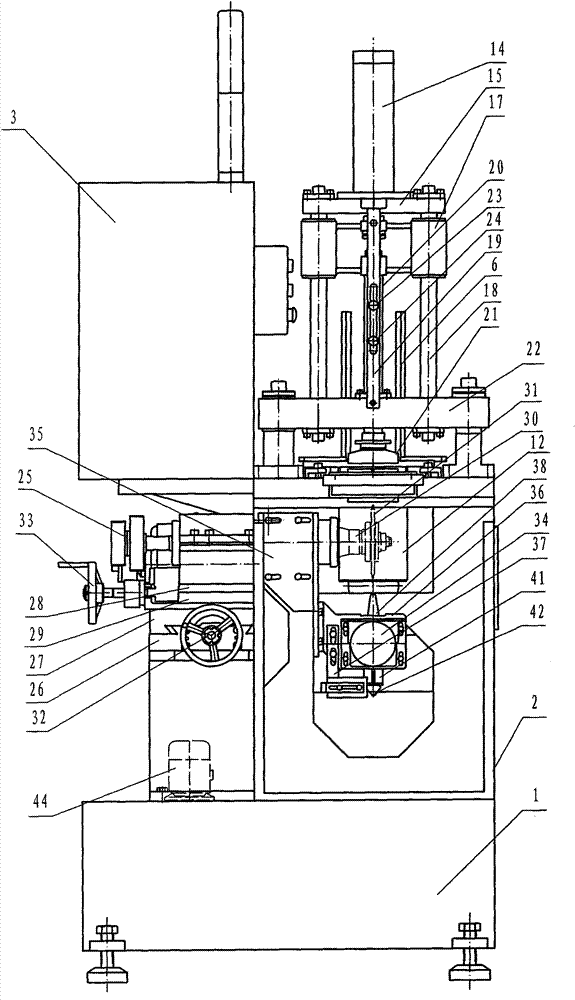

[0020] Depend on figure 1 ,Depend on figure 2 It can be seen that the present embodiment includes a base 1, a frame 2 fixed on the base 1, an electric control device 3 and a cooling device 44 fixed on the frame 2, and a feeding device, a feeding device, a pressing device, a grinding head device and ring device.

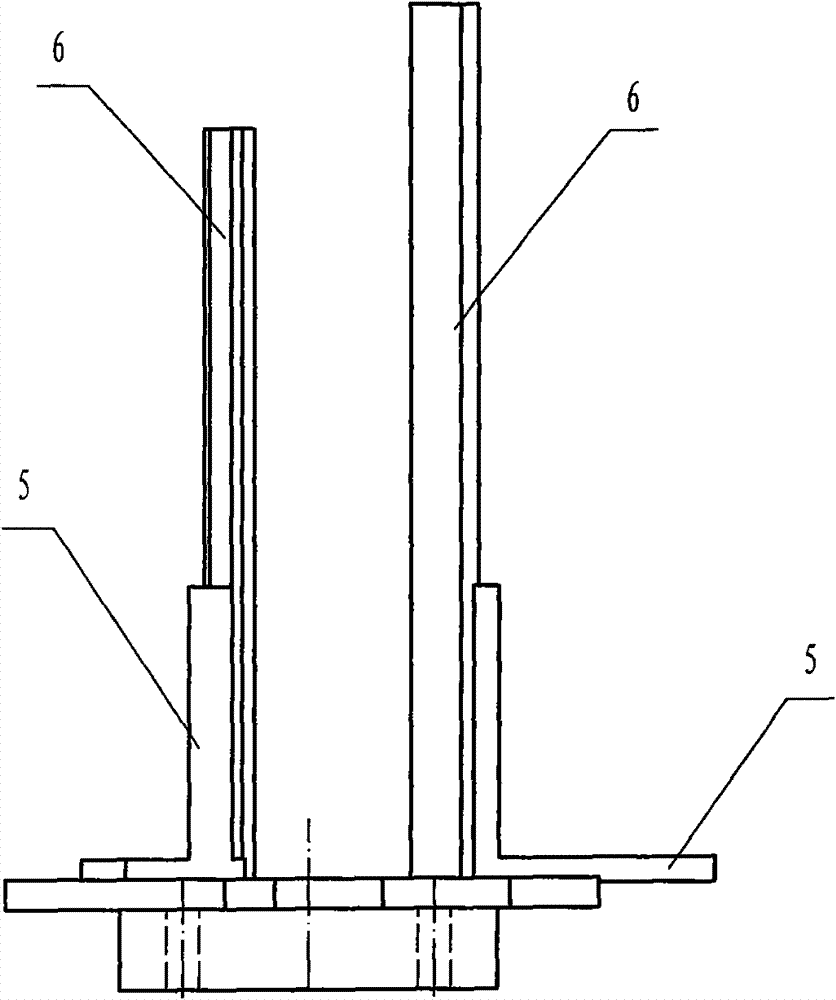

[0021] Depend on figure 1 , figure 2 , image 3 , Figure 4 It can be seen that in this embodiment, the feeding device is fixed on the workbench on the frame 2, which is composed of an annular bracket plate 4 with a hole in the middle, three "L" shaped adjustment frames 5 and three "L" shaped adjustment frames. "" shaped adjustment frame 5 is composed of three guide fixing rods 6 corresponding; three "L" shaped adjustment frames 5 are fixed on the ring bracket plate 4, and the transverse right-angled sides an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com