Functional keratin surfactant and method of producing simulated hair by using same

A surfactant and keratin technology, applied in wigs, applications, fiber processing and other directions, can solve the problems of curly hair being difficult to shape, poor product processing performance, and lack of promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

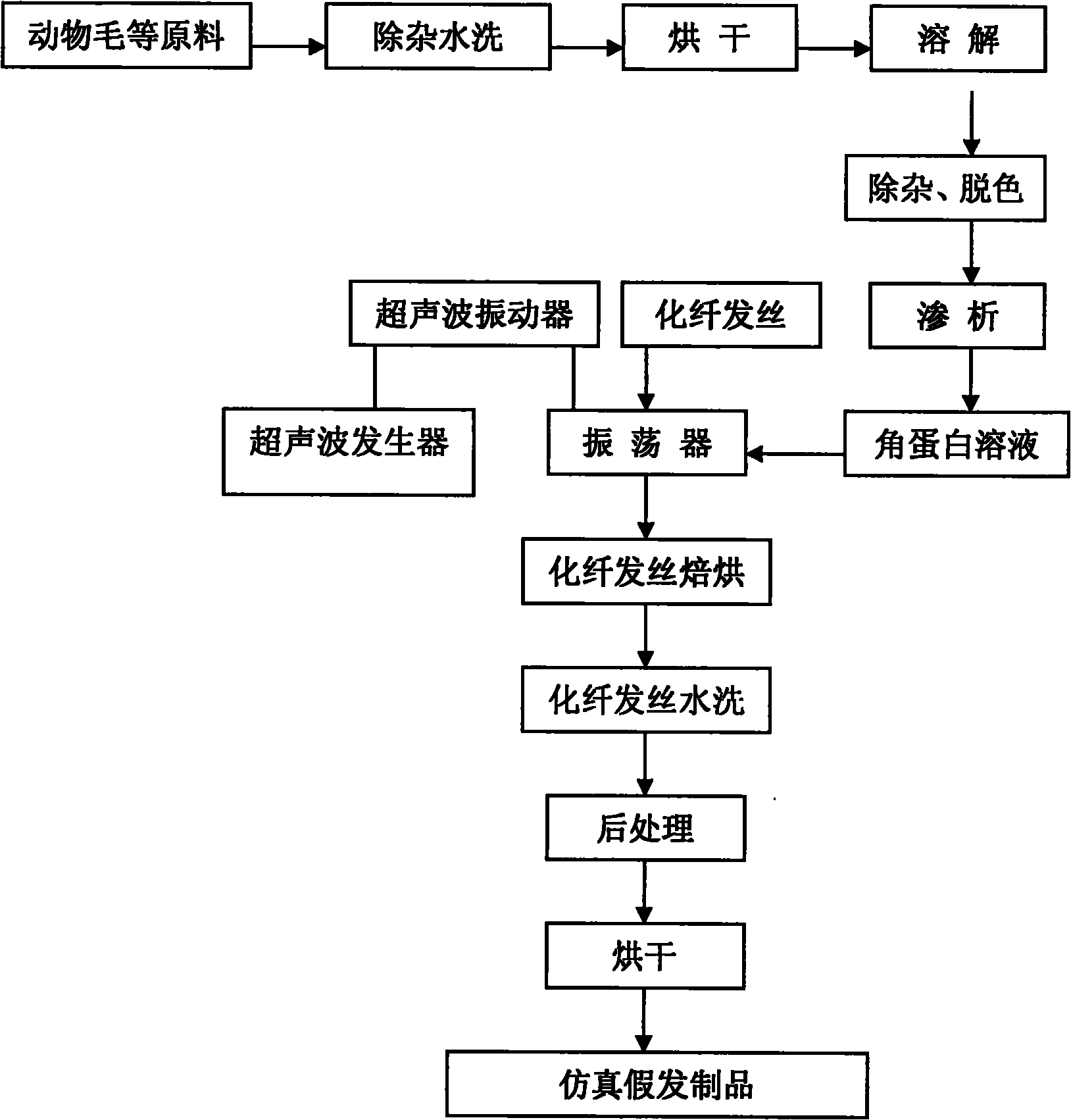

preparation example Construction

[0010] In the preparation of the functional keratin surfactant solution, the recycled human hair dregs, short human hair dregs, animal hair or horn hoof debris are used to dissolve them with an ionic liquid. lysate.

[0011] In the treatment of functional keratin surfactant liquid on the surface of chemical fiber hair, the functional keratin surfactant solution prepared above is absorbed on the surface of chemical fiber hair by using the principle of ultrasonic conduction and vibration, and improves The chemical reaction activation energy between the functional keratin surfactant solution and the surface of chemical fiber hair can increase the content of chemical fiber hair binding and adsorption keratin, so that the chemical fiber hair adsorption and binding liquid keratin can be evenly fixed on the surface of chemical fiber hair; Remove the chemical fiber hair that has been adsorbed and combined with the functional keratin surfactant solution from the solution, and immersed ...

Embodiment 1

[0012] Embodiment 1: as figure 1 Shown, a kind of functional keratin surfactant, is characterized in that: first add the sodium hydroxide of 130g and the sodium carbonate of 25g in the deionized water of 2000g, then add the human hair of 100g through impurity-removing washing and drying One of hair dregs, short human hair dregs, animal hair, and horned hoof debris, dissolve human hair dregs, human hair dregs, short human hair dregs, One of animal hair or horn hoof debris, the liquid obtained from this chemical reaction is filtered to remove impurities and decolorized, and then dialysis is performed twice through a dialysis device. The keratin solution is adjusted to pH and added with an appropriate amount of antibacterial agent to obtain a keratin surfactant.

[0013] A method for producing artificial hair with the above-mentioned functional keratin surfactant, which is characterized in that: using the conduction and vibration principles of ultrasonic waves, the chemical fibe...

Embodiment 2

[0014] Embodiment 2: as figure 1 Shown, a kind of functional keratin surfactant, is characterized in that: first add the sodium hydroxide of 145g and the sodium carbonate of 30g in the deionized water of 2000g, then add the human hair of 100g through impurity-removing washing and drying One of hair dregs, short human hair dregs, animal hair, and horned hoof debris, the human hair dregs, short human hair dregs, human hair dregs, short human hair dregs, One of animal hair or horn hoof debris, the liquid obtained from this chemical reaction is filtered to remove impurities, decolorized, and dialysis, and the keratin with too large molecular weight and too small molecular weight is removed through the dialysis device, and the keratin solution with moderate molecular weight is added to an appropriate amount Antimicrobial agents, namely derived keratin surfactants.

[0015] A method for producing artificial hair with the above-mentioned functional keratin surfactant, which is chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com