InP-based strained quantum well structure with pseudo-substrate and preparation method thereof

A quantum well and substrate technology, which is applied in the field of InP-based strained quantum well structure and preparation, can solve the problems of single-layer potential well or barrier layer thickness limitation, and achieve the effects of increasing critical thickness, good versatility, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

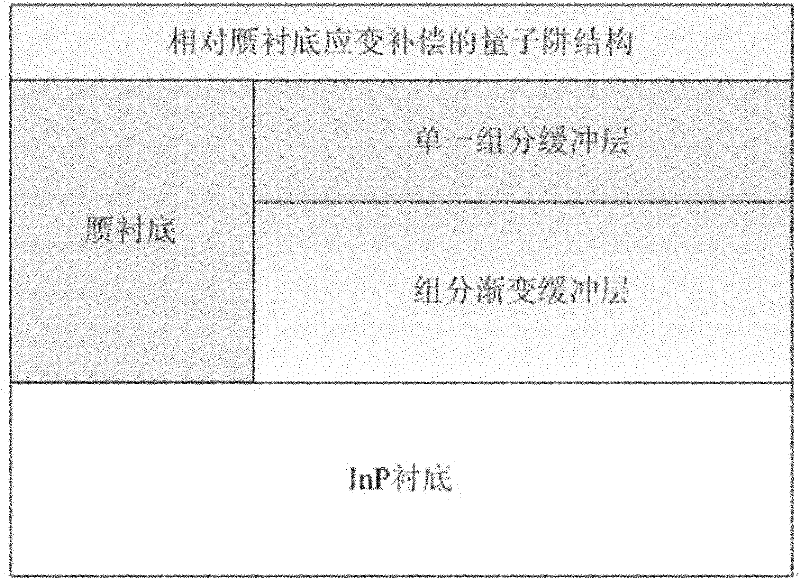

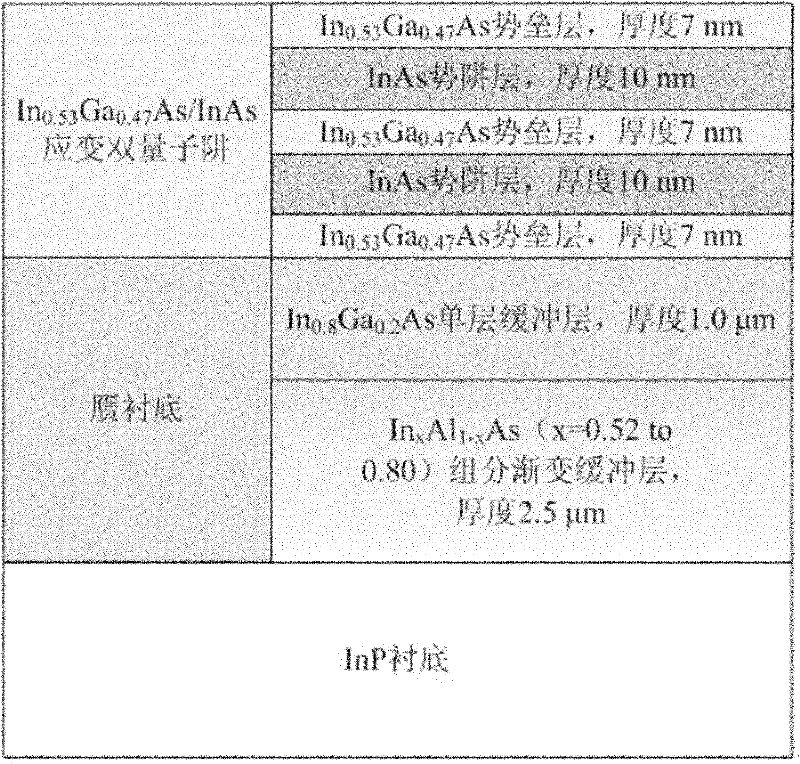

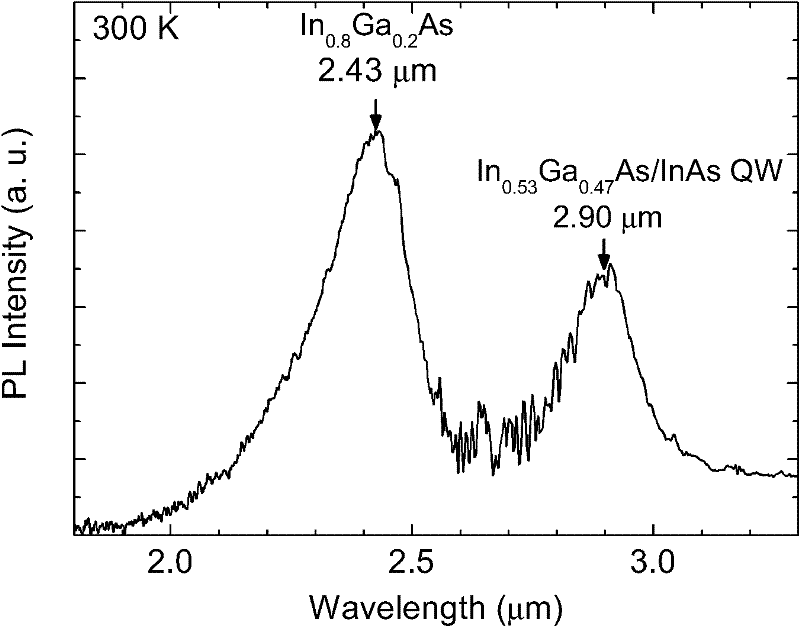

[0030] (1) Using molecular beam epitaxy to grow materials, such as figure 2 As shown, the thickness of the InAs potential well layer in the quantum well is 10nm, and the InAs 0.53 Ga 0.47 The thickness of the As barrier layer is 7nm, and the quantum well structure is relatively In 0.8 Ga 0.2 The As single-layer buffer layer constitutes strain compensation, and the number of quantum wells is taken as 2, that is, a double quantum well structure is grown. If the quantum well structure is grown directly on the InP substrate, since the potential well layer has a large mismatch with the substrate and the potential well is as thick as 10nm, the InAs potential well will relax and cause the material quality to degrade extremely, so A pseudo-substrate was constructed on an InP substrate with a gradient buffer layer and a single-component buffer layer. In x al 1-x The As buffer layer has a higher ratio than the In x Ga 1-x As buffer layer better performance and In x al 1-x As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com